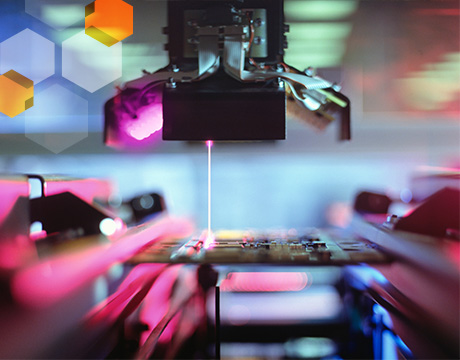

Ultrafast lasers emit ultrashort light pulses with incredibly short durations, allowing very high precision for many applications. Courtesy of Diamond Vision.

Introduction to Ultrafast Lasers

The ultrafast laser is a category of laser that emits ultrashort light pulses with time spans of femtoseconds or picoseconds. To put this in perspective, ultrafast lasers pulse light for around 100-trillionth of the time it takes for the average human to blink just once. Such minuscule durations approach the timescales of fundamental atomic and molecular processes and chemical reactions once unobservable by mankind. Today, their ability to deliver energy at unimaginable speeds allows ultrafast lasers to easily probe fragile structures and perform minute modifications at record speeds.

Operating Principle

While there are several types of ultrafast lasers, such as titanium-sapphire and diode-pumped based, ultrafast lasers constructed on pulsed fiber laser technology are one of the most common. A fiber laser is a type of laser utilizing optical fibers doped with rare-earth elements as their active gain medium. Fiber lasers provide a stable and reliable platform for the generation of the incredibly short pulses exhibited by ultrafast lasers.

Three important factors that govern the performance of ultrafast and pulsed fiber lasers are the duration of the pulse, repetition rate of the pulse, and the energy and average output power of the pulse. Ultrashort lasers utilize mode-locking, which is the driving method used to obtain ultrashort pulses from lasers. A simple laser cavity includes an arrangement of optical components allowing a light beam to circulate in a closed path. In this cavity, electromagnetic waves oscillate independently. Because the relative phases of these waves are random, the output of the laser displays random fluctuations, like noise, that continue to repeat each time waves travel though the cavity.

However, using the mode-locking operation, which can be achieved using a number of methods, the phases of these waves are “locked.” This results in constructive interference, or the event in which two or more waves of equal frequency combine to form a single wave with an amplitude equaling the sum of the individual waves. Interference will occur periodically and results in a train of intense pulses that repeat corresponding to the time it takes for the waves to travel through the cavity.

Advantages Over Other Laser Types

As mentioned previously, fiber lasers are a sound technology that provide a strong foundation for the development of ultrafast lasers. In comparison to other laser types, such as solid state lasers, ultrafast fiber lasers present a variety of advantages. One of these advantages is a high power output; fiber lasers can support kilowatt levels of continuous output power. Due to the long, thin nature of gain fibers and high surface area to volume ratio, cooling is much more efficient. Additionally, fiber lasers offer high optical quality provided through wave-guiding properties that reduce thermal distortion of the optical path.

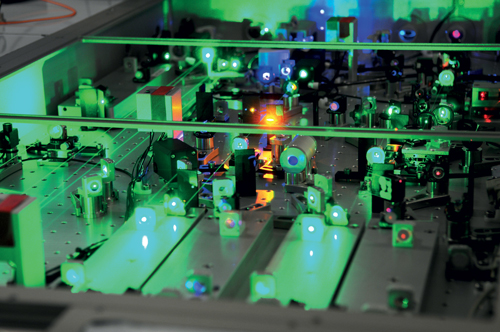

Laser machining utilizes ultrafast laser systems for more efficient and cost effective manufacturing. Courtesy of The American Society of Mechanical Engineers.

Furthermore, fibers can be bent and coiled, allowing for a compact size compared to gas lasers of similar power. They are reliable through high temperatures, have vibration stability, an extended lifetime, and are relatively easy to maintain. With a low cost of ownership, they are becoming more and more accessible to a variety of industries. In addition, they are versatile, as they can operate in the infrared, visible, and shorter ultraviolet range. Their high peak power and nanosecond pulses prove to be useful for effective marking and engraving, providing clean cut edges and faster cutting speeds in the field of laser machining. Unlike lasers with longer pulse widths, ultrafast lasers result in minimal residual damage or stress in the material.

Applicationshttps://www.findlight.net/lasers/gas-lasers/co2

Ultrafast laser systems can measure and manipulate atoms and molecules and explore the nature of chemical bonds, vibrations and reactions. Above all, ultrafast laser systems have enabled scientists and engineers to understand the world like never before. With new understanding comes the ability to produce and manufacture products with higher quality and relevance to today’s society.

One of the most common uses of ultrafast lasers is in laser machining. From manufacturing extremely thin films to industrial manufacturing of cars, aircraft, ships and robots, laser machining has truly endless applications. Utilizing ultrafast lasers in laser machining and processing allows for a carefully controlled, non-contact process.

Because ultrafast lasers deliver a precise light concentration over such short durations, no heat damage occurs to the surrounding material. This also correlates to minimal residual debris. Thus, the high power laser provides a clean final product that does not require the secondary finishing processes that traditional machining does. This saves companies considerable amounts of time and money. In fact, the amount of time the ultrafast laser is in contact with a material is typically three to six orders of magnitude less than conventional laser processes.

Ultrafast lasers are ideal for manufacturing tiny medical devices, such as cardiovascular stents. Courtesy of Industrial Laser Solutions.

Laser machining is also crucial in medical device fabrication for manufacturing cardiovascular stents, balloons and catheters. Ultrafast lasers can process metal or plastic with great precision. Thus, they are in high demand for the production of medical devices constructed of such materials. Approved by the FDA in 2001, laser eye surgery for vision correction also utilizes ultrafast lasers. Using this technology, surgeons are now able to create precise flaps in the cornea, providing better patient safety and a quicker recovery time.

Market Size

In the next five years, experts predict a growth rate of about 6% for ultrafast laser technology. Additionally, they expect this to exceed $17 billion in value by the year 2020. The predicted growth is driven by expanding use of laser processing in advanced manufacturing industries like aerospace, automotive, and biomedical.

With devices becoming smaller and more complex, the demand for precise, accurate and efficient manufacturing technology is thriving. Ultrafast lasers may be just steps away from solving fundamental engineering questions currently limiting the progress of several different technologies. The applications for ultrafast and pulsed fiber lasers continues to expand as researchers dive deeper into unexplored areas of knowledge.

Experts predict the ultrafast laser market to grow steadily as technology continues to advance. Courtesy of Electro Optics.

For example, a recent study investigates the use of lasers to create brand new materials not yet observed by humans. These brand new materials could potentially exhibit unique properties that open the door to new discoveries in the near future. In medicine, ultrafast lasers are still under investigation for bone and cartilage repair, tissue engineering, dermatology, intra-operative diagnostics and more. Lastly, the need for higher-capacity batteries has risen with the awareness of climate change and call for technologies such as all-electric cars. In order to develop such batteries, engineers need to better understand the electrochemical reactions involved before they can solve the cost, performance and capacity issues that currently limit the technology.

Overall, ultrafast lasers offer a sophisticated tool to the developing world as the demand for improved technology increases. The high power, high precision, and excellent quality offered by these systems strives to meet these demands, while also paving the way for new innovations and research.

Your blog is very useful and provide tremendous facts. It is going to change the way one think by a sharp angle.