Laser beam parameters are the subject of this post. Choosing the type of laser for your experiment or project may be a daunting task. With so many beam parameters to select from, how do you know where to start? One of the best ways to tackle any task is to identify what exactly you need, and what is available. Here, we will first proceed with the most common beam parameters in order to address broad situations. These parameters are crucial to the success and failure of your projects. Knowledge of these factors can help you reproduce results more uniformly and accurately. It will make things more manageable and reduce problems that could ultimately become stress for you. We all want our experiments to run more efficiently and within your budget. Studying these parameters can help you achieve that goal, and more with your projects.

With these parameters in mind, choosing the right tool for usage may be confusing at the start. This is the first article in a series where we will explore how to choose different tools for detecting light. As mentioned previously, we will start in this article with an introduction to the most common laser beam parameters to consider. With this guidance, the question of when and how to use each tool should quickly become more clear.

Primary Laser Beam Parameters

The primary laser beam parameters people consider are power and wavelength. First, power determines how much energy is incident upon the material the laser is pointed at. If the laser’s power is higher than the ideal level, it will waste resources or damage the sample. However, if the power level is lower, the project will take longer to complete or might not produce results at all.

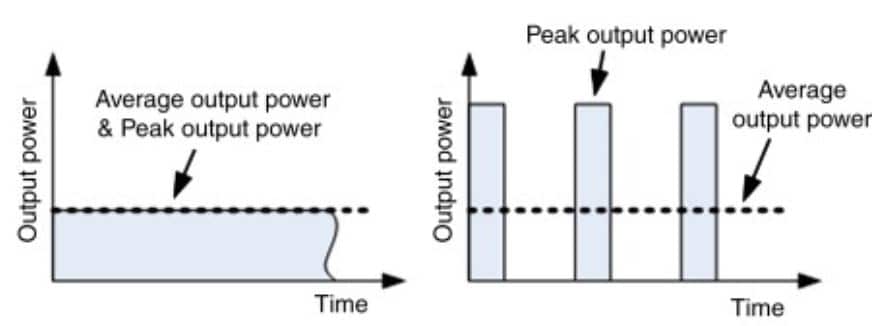

Another important aspect of power is the operation modes. There are two main operation modes for lasers, pulsed and continuous. Pulsed modes act as their name suggests, and their peak power is what determines accurate results. On the other hand, in a continuous wave lasers, maintaining the high or low power states stably is very important. Often people consider other parameters called intensity and energy. However, these parameters are closely related to power and for this simple introduction we will leave them out as extra reading.

Next, we have the wavelength of a laser. This parameter is determined by the photon energy level in the beam. To clarify, shorter wavelengths mean higher energy levels and longer wavelengths correlate to lower energies. Additionally, shorter wavelengths give higher resolutions and focalization. In a good laser, the wavelength shouldn’t vary too much over time and should be very consistent.

Illustration of the peak output power and the average output power of a CW laser beam (left) and pulsed laser beam (right). Courtesy of Zhang et al.

Other Common Beam Parameters: Beam Diameter and Profile

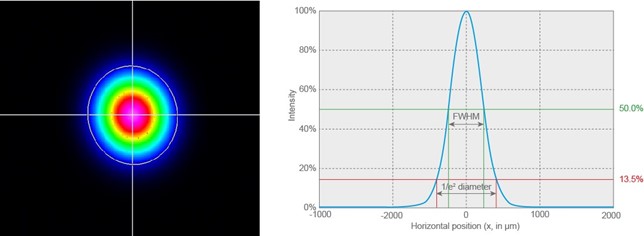

The next most common laser parameters besides power and energy are beam diameter and beam profile. First, the beam diameter is defined as twice the radius of the beam. However, this radius is often hard to measure for lasers. This is due to how vague the edges of a laser beams are. To illustrate, measuring the exact diameter of a beam is like trying to measure the exact border of a cotton ball. Thus, some definitions are different from others, but there are two commonly used ones. One says that the diameter of the beam is where the peak intensity reduces by a factor of 1/e². Another definition says the diameter is determined by the full width at half-maximum (FWHM) length. At this point, the beam has 86% of its original energy. You should use the definition that fits best with your specific operation and laser.

Secondly, the profile parameter (aka spatial intensity distribution) accounts for a beam’s mechanical, thermal and electromagnetic properties. Intensity profiles can help tune lasers and diagnose issues or errors. To clarify, this is because power distribution in a laser beam depends on many different aspects. First and foremost, the power depends on the modes that propagate within the laser cavity. These modes can be refracted and distorted by a series of surfaces and other apertures, which in turn affect the power distribution. Due to this nature, it is complicated and difficult to determine just one cause of a perturbation. Thus, looking at this setup through holistic measurements, with a beam profiler, helps bring more clarity to the situation.

Left image showing color gradient representing density of photons in laser beam section. Right graph shows two definitions of beam diameter measurement. Courtesy of Gentec.

Divergence and Beam Quality Factor

Third, the divergence of a laser beam measures the rate of beam expansion as it moves in space. In other words, beam divergence is the derivative of the radius with respect to the axis in the far field. Of course, this definition depends on how the radius is defined, which we mentioned can vary. Furthermore, divergence can also be measured through a camera based beam analyzer. Namely, this requires a lens or confocal mirror in the laser path. Along with that, the sensor or sensor’s reach should be placed right at the focal length of this lens. Following, a far field image of the beam can be captured. It should be noted that the sensor placement determines whether or not the user gets a correct measurement. In addition, small divergences have constant beam diameter, producing collimated beams. These have a variety of uses from X-rays to displays.

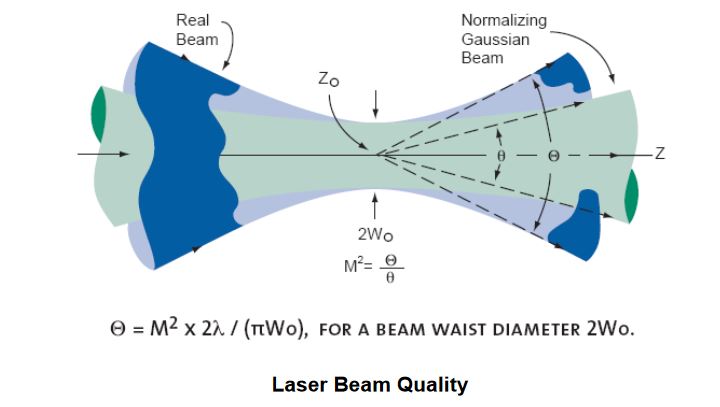

The fourth and last parameter is the beam quality factor, a.k.a. beam parameter product M². This factor is a measurable quantity and characterizes mixed-mode beams. Mixed mode beams are M² times larger than perfect Gaussian beams. To illustrate, M² for perfect Gaussian lasers is equal to 1. For other beams, M² is greater than 1. In the real world, this factor is never exactly one due to perturbations from refraction, imperfect or dirty apertures and other components.

Diagram showing non-Gaussian beam over a perfectly Gaussian beam. Beam parameter product is the ratio of the two angles created by these beams with respect to the z axis. Courtesy of Coherent.

Conclusion

As we have discussed, there are many parameters to consider when choosing a laser or detector. It is important to keep this in mind to keep costs and processing time down, both of which may determine your success. In the next article in this series, we will take a look at several different tools. Taking it on a case by case basis, we will introduce how and when to use these tools. The goal of this series is to help someone find the next tool that will lead them on the right path.

This post was sponsored by Gentec Electro-Optics, Inc. - world leader in laser beam measurement solutions