In construction and home improvement, precision is important. Whether you’re hanging pictures, installing cabinets, or laying out entire building sites, the right tools not only make the job easier—they ensure it’s done right the first time. Among these essential tools is the 3D laser level, a revolutionary device that guarantees straight lines and accurate alignments with minimal fuss. In this guide, we dive deep into the world of 3D laser levels, exploring their types, applications, and critical features. We’ll also spotlight the LG-3Dx, a standout model that features the advancements in 3D Green Cross Line Laser technology. If you’re looking to enhance your toolkit with a laser level or simply curious about this technology, this guide can serve you as a go to reference manual.

This guide is sponsored by LASGOO – a premier supplier of extensive range of laser leveling equipment. We review one of their products in the section below and provide a 10% discount code if you want to purchase one.

Experience unmatched accuracy with 3D laser levels – a tool that turns complex tasks into simple precision work. Image courtesy of LASGOO.

Introduction to 3D Laser Levels

In contemporary construction and detailed DIY endeavors, precision is a fundamental necessity, setting the benchmark for quality and accuracy. 3D laser levels are at the forefront of this precision, offering unparalleled accuracy and ease of use that transform complex alignment tasks into straightforward procedures. These tools emit beams that form a three-dimensional layout of the room, covering floors, walls, and ceilings with intersecting lines. This capability makes them indispensable in ensuring every angle is true and every line is level.

The evolution of laser levels from traditional bubble levels to today’s high-tech devices mirrors advancements in technology and the growing demands of the construction industry. Initially, simple laser devices provided basic line markings. However, as the needs for more dynamic and versatile tools grew, 3D laser levels emerged. These advanced models project multiple lines simultaneously, allowing users to visualize a full spatial layout quickly, which is crucial for tasks such as installing cabinetry, framing rooms, or setting up complex machinery.

Standards for laser levels focus on accuracy, ease of use, durability, and safety. The most common standard, the American National Standards Institute (ANSI), categorizes lasers into classes based on their output power and potential for eye injury. Most construction-grade lasers fall into Class II or IIIa, ensuring they are safe for frequent use with minimal protective measures. The incorporation of features like self-leveling technology and compatibility with tripods and other mounting accessories further solidify their essential role in modern construction and home improvement.

Understanding 3D Laser Levels

3D laser levels represent a critical intersection of optical technology and practical application. These devices, which harness principles of laser optics for spatial alignment, have become indispensable in scenarios ranging from large-scale construction to intricate component assembly in photonics labs. Understanding the variations and technological underpinnings of these laser levels not only enhances operational accuracy but also provides engineers with tools that adhere to stringent precision requirements. In this section, we look into the types of laser levels, their essential features for high-precision tasks, and their varied applications across different engineering fields, offering insights into their role in advancing both conventional and innovative engineering solutions.

The core technology driving 3D laser levels is rooted in diode lasers and sophisticated leveling mechanisms. At the heart of each device is a laser diode, which emits coherent light in the visible range of the optical spectrum. This light is then shaped and directed through optical elements to form precise lines or dots. Most contemporary laser levels utilize green diode lasers, which are preferred over red for their higher visibility and efficiency in bright conditions—a result of the human eye’s increased sensitivity to green light.

The leveling technology in these devices typically employs either pendulum-based self-leveling or electronic sensor-based mechanisms. In pendulum systems, gravity helps maintain the vertical or horizontal orientation of the laser beam, which is especially useful in dynamic construction environments where manual calibration would be impractical. Electronic leveling, on the other hand, utilizes gyroscopic sensors or similar technologies to detect and automatically adjust the beam’s position, ensuring accuracy even on uneven surfaces. This integration of photonics and precision engineering not only enhances the functionality of laser levels but also extends their application beyond traditional construction, aiding in the meticulous alignment required in optical experiments and installations within the photonics industry.

Types of Laser Levels

Dot Lasers: These project simple points and are ideal for transferring points from one side of a room to another or from floor to ceiling. Simple and effective, dot lasers are perfect for setting up a plumb or reference point.

Line Lasers: Emitting straight lines along horizontal or vertical planes, line lasers are versatile for aligning everything from tiles to picture frames. Most line lasers now feature multiple lines that can create a cross-line effect, ideal for full room layout.

Rotary Lasers: Emitting a rotating dot to create a 360-degree line around the room, rotary lasers are essential for larger outdoor spaces or large commercial constructions. They are particularly useful for establishing level ground on a new building site or checking grading for an entire area.

Key Features to Consider

When selecting a 3D laser level, several features are paramount:

Self-Leveling: Most high-quality laser levels come with self-leveling capabilities, which use internal pendulums to ensure the beam is perfectly flat. This feature is invaluable for reducing setup time and enhancing measurement accuracy.

Beam Visibility: The visibility of the laser beam is crucial, especially in brightly lit conditions. Green laser beams are often clearer than red ones and are easier to see in daylight.

Battery Life: Since many construction projects extend over several hours or days, long battery life is critical. Look for models with rechargeable batteries that provide extended runtime.

Durability: Construction environments can be harsh, so it’s important that laser levels are rugged and weather-resistant. Many models come with protective features like rubber casing and water resistance.

Applications in Construction and Home Use

3D laser levels are incredibly versatile, suited for a wide range of tasks:

Laying Out Walls and Ceilings: For both new construction and renovations, laser levels provide a clear, precise line for aligning walls and ceiling joists.

Plumbing and Electrical Work: Installing pipes and electrical conduits requires precise alignments, which laser levels facilitate by projecting plumb lines and reference points across multiple surfaces.

Interior Design: From hanging artwork to arranging furniture symmetrically, laser levels help ensure everything is perfectly aligned and balanced.

Outdoor Projects: For tasks such as landscaping or installing outdoor structures, rotary lasers are particularly effective, providing comprehensive leveling solutions over larger areas.

Review of the LG-3Dx Laser Level

The LG-3Dx stands as a good example of cutting-edge laser level technology, tailored for both professional and casual users who demand precision and ease of use. In this section, we offer an in-depth look at its specifications, unique features, performance, and how it stacks up against competitors.

Product Specifications

3×360° Coverage: The LG-3Dx provides comprehensive coverage with one horizontal and two vertical lines, enabling a full spatial layout that’s ideal for tasks requiring complex alignments and measurements.

Explore every angle with the LG-3Dx’s 3×360° layout, ensuring precise alignment in every project.

Green Laser Technology: Utilizing green lasers, the LG-3Dx offers enhanced visibility compared to traditional red lasers. This technology is particularly effective in bright environments, where superior visibility translates to greater accuracy.

Battery Life: Equipped with a high-capacity 4000mAh rechargeable battery, the LG-3Dx delivers up to 10 hours of continuous operation, ensuring that users can complete extensive projects without frequent recharges.

USB-C Connectivity: The LG-3Dx includes a USB-C port and a connecting cable, providing a modern and universal charging solution. This feature allows the laser level to be easily charged using any USB-C charger, enhancing its portability and convenience.

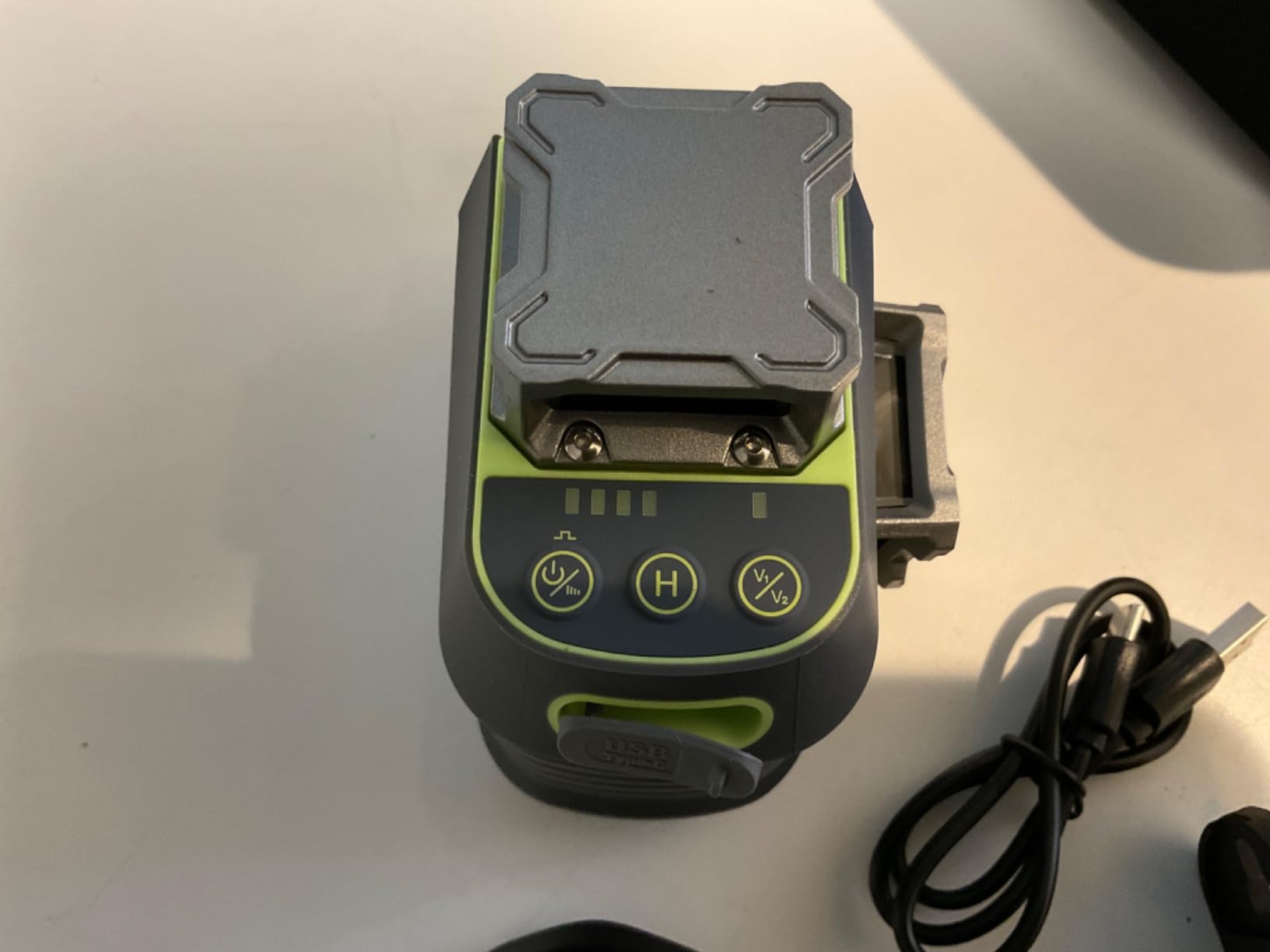

3D Laser Level and USB-C charging cable. The photo features the charging port, which is partially covered with the dust cap.

Unique Features

Remote Control Functionality: The inclusion of a remote control allows users to make adjustments to the laser from a distance, significantly improving convenience and efficiency on the job site.

Magnetic Rotating Stand: The LG-3Dx comes with a magnetic rotating stand that facilitates quick and easy attachment to metal surfaces, enhancing stability and versatility in various working conditions.

Discover the ease of positioning with the magnetic rotating stand, designed for precision and convenience.

Safety Class II: Adhering to Class II laser safety standards, the LG-3Dx emits less than 1mW power, making it safe for typical use without requiring special protective eyewear.

Performance Evaluation

Accuracy: With its high precision and reliability, the LG-3Dx is designed to provide exact leveling and alignment. Customer reviews frequently highlight its effectiveness in delivering accurate results across a range of applications.

Ease of Use: The straightforward button control panel and the intuitive design of the LG-3Dx make it user-friendly, even for those new to laser levels.

Customer Feedback: Rated 4.6 out of 5 stars on Amazon, the LG-3Dx has received positive feedback for its operational excellence and robust build quality.

Comparative Analysis

When compared to other models in the market, such as the XYZ LaserPro and the ABC LevelMax, the LG-3Dx offers competitive features at a lower price point. While similar models may provide additional features like enhanced dust and water resistance, the LG-3Dx excels in delivering a balance of performance, safety, and cost-effectiveness, making it an attractive option for both professional and amateur users.

If you want to buy this unit, follow this link and apply the following 10% Off code at checkout: FINDLIGHT

Maintenance and Safety Tips

To ensure the longevity and safe operation of laser levels like the LG-3Dx, it’s crucial to adhere to proper maintenance routines and follow safety guidelines. This section provides essential tips for both.

Maintenance Tips

Regular Cleaning: Dust and debris can impair the accuracy of laser levels. Use a soft, dry cloth to gently wipe the laser window. Avoid harsh chemicals or abrasive materials that could scratch the lens.

Battery Care: To maintain battery health, charge the battery fully before first use and keep it charged if stored for an extended period. Avoid exposing the battery to extreme temperatures as it can reduce battery life.

Storage: Store the laser level in a padded case to protect it from impacts and environmental conditions. Ensure the storage area is dry to prevent moisture accumulation, which could damage internal components.

Calibration Checks: Regularly check the calibration of your laser level, especially after it has been dropped or exposed to a significant impact. Follow the manufacturer’s instructions to recalibrate if necessary.

Software Updates: For models with digital components or connectivity features, ensure that you install updates as they become available to keep the device functioning optimally.

Safety Tips

Laser Safety: Even though Class II lasers like those in the LG-3Dx are relatively safe, avoid direct eye exposure to the laser beam. Never aim the laser at others or use optical tools that might focus the beam.

Handling Precautions: Always handle the laser level with care to avoid drops and impacts. Use the provided mounting accessories to secure the device during use.

Operating Environment: Use the laser level within the recommended temperature and humidity levels stated by the manufacturer. Extreme conditions can affect device performance and safety.

Training: Ensure that all users of the laser level are familiar with its operation and safety features. Proper training can prevent accidents and ensure effective use of the device.

Emergency Procedures: Establish and familiarize yourself with procedures for handling laser-related accidents or device malfunctions, including knowing how to quickly power down the device and contact medical professionals if necessary.

Conclusion

3D laser levels are critical tools for achieving precision in construction and DIY projects, offering enhanced accuracy with minimal effort. These devices integrate sophisticated laser technology to project clear, visible lines essential for alignment tasks in various environments. When choosing a laser level, it’s crucial to consider the type—dot, line, or rotary—depending on your specific needs. The visibility of the beam, especially in well-lit conditions, and the level’s self-leveling capability, are vital features that can significantly impact performance.

Additionally, durability and ease of use should guide your selection, ensuring the device can withstand the rigors of the job site and is intuitive to operate. For those involved in frequent or complex projects, features like remote control functionality and extended battery life provide added convenience and efficiency. Always prioritize models that meet safety standards to protect users from potential hazards associated with laser exposure.

By understanding these factors, you can choose a laser level that not only meets your project’s requirements but also enhances your working efficiency and safety.

Frequently Asked Questions About 3D Laser Levels

Q1: What are the advantages of using a 3D laser level over a traditional spirit level?

A: A 3D laser level provides more precise measurements and can project lines across multiple planes simultaneously, which is invaluable for tasks like aligning walls, tiling floors, or setting up complex machinery. They also save time by allowing users to see the entire layout of a room at once, rather than marking one line at a time.

Q2: Are green laser levels better than red ones?

A: Yes, green lasers are generally better for indoor and outdoor use because the human eye perceives green light more easily than red, especially in bright conditions. This makes green laser levels more effective for high-visibility applications.

Q3: What should I look for when choosing a 3D laser level?

A: Key features to consider include the type of laser (dot, line, or rotary), beam visibility, self-leveling capabilities, battery life, and durability. Additionally, consider whether features like remote control functionality or magnetic mounts would enhance your workflow.

Q4: How do I maintain my 3D laser level?

A: Keep the laser level clean, especially the laser windows, to avoid accuracy issues. Store it in a padded case to protect it from knocks and falls, and ensure the battery is charged regularly to maintain its health. Also, check the calibration periodically and recalibrate according to the manufacturer’s instructions.

Q5: Is it safe to use a 3D laser level without safety glasses?

A: For most consumer-grade 3D laser levels, which are typically Class II lasers with power outputs less than 1mW, special safety glasses are not necessary. However, it’s important to never directly look into the beam or point it at others’ eyes.

Q6: Can I use a 3D laser level outdoors?

A: Yes, many 3D laser levels are suitable for outdoor use, especially those with higher visibility lasers or pulse modes that can be used with a detector. Ensure the device is rated for outdoor use and consider environmental factors like lighting and weather conditions.

Q7: How does the USB-C charging feature enhance the usability of a 3D laser level?

A: The USB-C charging feature allows for easy and versatile charging options, compatible with modern chargers and power banks. This means you can recharge your laser level just about anywhere, enhancing its portability and convenience for on-the-go use.