Introduction

The construction industry has always been at the forefront of innovation and advancement, constantly finding new ways to improve efficiency and reduce waste. In recent years, the introduction of 3D printing technology has sparked a revolution in the industry, offering various benefits previously unimaginable. From the ability to create highly customized designs, to the potential for on-demand production and on-site construction, 3D printing can completely transform how we think about building and constructing structures. In this blog post, we will explore how 3D printing is revolutionizing the construction industry.

3D Printing

Additive manufacturing, or 3D printing, is a process of creating a physical object from a digital model by building it up layer by layer. Smaller-scale 3D printers, such as those used for hobbyist or prototyping purposes, typically use molten plastic as the building material. These printers deposit the plastic, layer by layer, onto a level platform using stepper motors to position the heated head. The printer creates the model within a few hours by following the instructions of a 3D Computer-Aided Design (CAD) “drawing,” which specifies the shape and dimensions of the object to be printed.

For more on 3D Printing visit: 3D Printing: Brief Introductory Guide

3D Printing in the Construction Industry

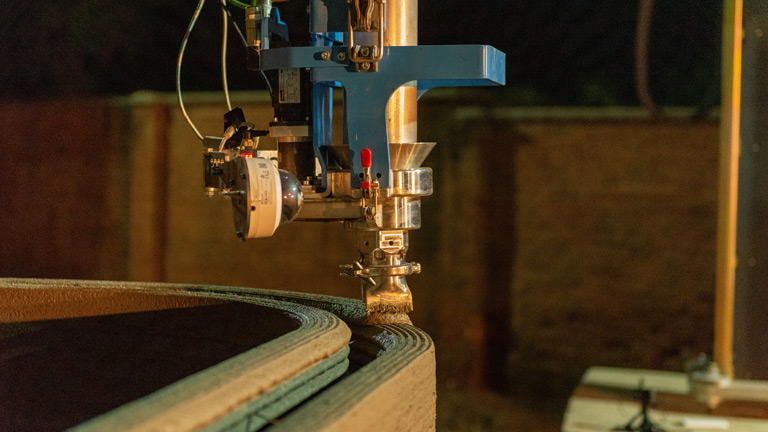

3D printing in the construction industry can be described as large-scale 3D printing, as the printers used are designed to handle the size and weight of building materials and print structures on a much larger scale than traditional 3D printers. These large-scale 3D printers are equipped with a nozzle or a print head that dispenses the building material, which can be a variety of substances such as concrete, a composite material, or even something like mud.

Benefits

Time Reduction

One way that 3D printing is changing the construction process is by enabling the use of a single machine to print entire structures, rather than relying on multiple trades and craftsmen to individually fabricate and assemble different parts of a building. This not only reduces the amount of labor required but also eliminates many of the coordination and scheduling challenges that can arise when working with multiple parties.

In addition to the on-site construction, 3D printing also allows for increased collaboration and design freedom. With the help of software such as BIM(Building Information Modeling) that allows for accurate simulation of the project, 3D printing enables the architect to take on multiple roles within the design process, such as the role of engineer or contractor. This leads to more direct communication, less time spent waiting for responses and faster completion of the project.

The printers alone are more time-efficient than manually constructed projects. Some printers can produce a 400 to 800-square-foot house in just 24 hours, while it traditionally takes a few months for a house of the same magnitude to be built with traditional construction methods.

It’s important to note that the time-saving factor experienced with 3D printing is highly dependent on the project, the printer, the material used, and other factors, however, in almost all cases the technology has the potential to significantly decrease the time and costs associated with traditional construction methods.

Low Material Waste

With the printer capable of precisely placing material layer by layer, minimal material waste is seen. Also, the digitalized model created using CAD software serves as the blueprint for the 3D printer, which eliminates the need for a physical, scale model. This not only reduces the environmental impact of construction but also makes construction more cost-effective by reducing the amount of materials required. The recycling capability of the technology allows for the repurposing of leftover materials for a different project, this feature is beneficial both financially and environmentally.

Design

Traditional building methods often face limitations in design options, but the integration of 3D printing technology in the construction industry opens up the possibility for creating unconventional structures. Architects can create complex, inorganic shapes that would be pretty much impossible to achieve with outdated methods.

Software

CAD

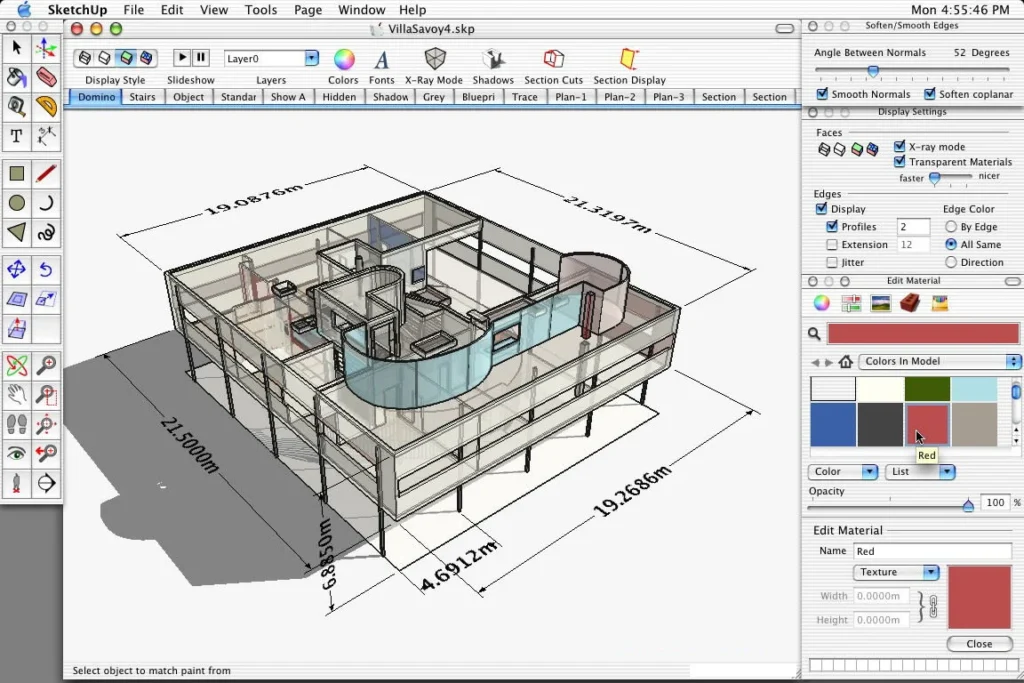

CAD, or Computer-Aided Design, allows for the creation and manipulation of 2D and 3D models, schematics, blueprints, drawings, etc. With the software, architects gain the ability to simulate and test the structural integrity of a building before it is constructed, further ensuring that the structure is stable and safe. Specific performance parameters: energy efficiency, weight distribution, and thermal insulation can be optimized through this software as well. To master these capabilities, many professionals find Autodesk training courses invaluable, especially when working with industry-standard tools.

There are many options for CAD software available for use in the industry, with the most popular being: AutoCAD, Solidworks, Rhino, and Sketchup.

BIM

BIM (Building Information Modeling), is quite similar to its CAD counterpart but tends to yield more accessible information that can be illustrated in 2D, 3D, or data tables. These models are usually more than 3D models of the project, they contain the dimensions and properties of the components in the project, which are stored in a BIM database.

The popular options for BIM software are Revit, ArchiCAD, Vectorworks, and Tekla.

Slicing Software

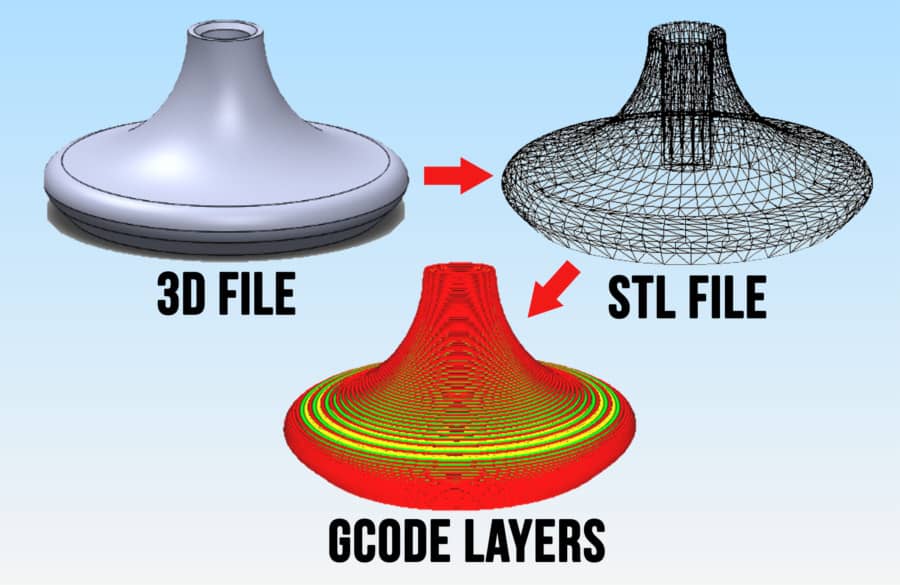

Photo courtesy of the 3Dbros.com

Slicing software is used to generate the G-code, which can be described as instructions that tell the printer how to place the material in the printing process. This kind of software takes the 3D model design and “slices” it into 2D layers, making the printing possible to be placed layer-by-layer. There is a variety of slicing software available, each differing in features and capabilities.

Within the G-code generated by the slicing software, there is information about the position, temperature, and needed speed of the extruder. The software specifically tells the printer how and when to move the extruder, where to place it on the build plate, and with how much material.

Embedded in the software is the ability to generate support structures, either by automatic or manual placement. Adhesion options are also available, specifically brim and raft.

Conclusion

In conclusion, 3D printing technology in the construction industry has the potential to revolutionize the way we approach building and construction with benefits such as time reduction, low material waste, and precise and accurate designs. The use of CAD, BIM, and slicing software in conjunction with 3D printing allows for a more efficient, cost-effective, and environmentally friendly construction process. The technology has the potential to change the future of building and construction as we know it.

External Sources

Guide to 3D printing in Architecture and Construction

Read more about how 3D printing is transforming the industry

https://www.technologycards.net/the-technologies/construction-3d-printing

This article is brought to you by Gentec EO, a leading developer and manufacturer of detectors and laser measurement solutions