Compound eyes provide insects with a large field-of view and heightened sensitivity to motion. Courtesy of Stanford News.

Compound eyes provide insects with the ability to quickly react to danger. These eyes posses a much wider field-of-view, higher light sensitivity, and superior sensitivity to motion when compared to the single-lensed human eye. These qualities make the structure of compound eyes of special interest to optical scientists and engineers. Artificial compound eye technologies could have profound effects in a wide variety of applications including photography, medicine, and military. A research group at Xi’an Jiaton Univeristy in China believes they have devised a low-cost, low-maintenance solution.

The Optics of Compound Eyes

The curved surface of the compound eye consists of an array of thousands of tiny optical features called ommatidia. Each ommatidia includes a lens, crystalline cone, light-sensitive visual cells, and pigment cells that ensure only light entering parallel to the optic axis trigger nerve impulses. These pigment cells therefore ensure that each individual ommatidia gathers information from a single area in space. The brain pieces each element together like a mosaic to form a final image with a very wide field-of-view. In addition, nanostructures on the eye provide antireflective and water-repellant properties.

The Need for a New Approach

Researchers have proposed many different methods for fabricating bio-inspired compound eyes. A few techniques of note include reactive-ion etching, nanoimprint lithography, and laser-assisted etching. The Xi’an Jiaton team, however, believes most of these methods are too complex and expensive for large-scale manufacturing. Moreover, the team cites inconsistent performance due to structural degradation of the nanostructures that occurs when transferring the lens array to the curved surface. They suggest a “curvature-compatible” technique would preserve the nanostructures and maintain desirable hydrophobic and antireflective properties.

The above graphic shows the process of creating the template and mold for the array of convex microlenses. Courtesy of ACS Nano.

Forming the Eye with Laser Swelling and Crystal Growth

Their approach involves creating convex structures through a process of laser swelling. The team formed a template for the microlenses by first exposing a dual-layer of acrylic glass (PMMA) to a highly focused femtosecond laser. The beam penetrates into the sample and focuses just below the surface where heating causes doped martial to vaporize. This creates a convex dome-like shape in the acrylic. The team was able to control the dimensions of these structures by adjusting laser power and irradiation time.

The array is fixed into a thin elastomer to form a mold of the template which is then placed over a larger curved chamber. The team fills this chamber with an epoxy resin to reinforce the structure of the “compound eye”.

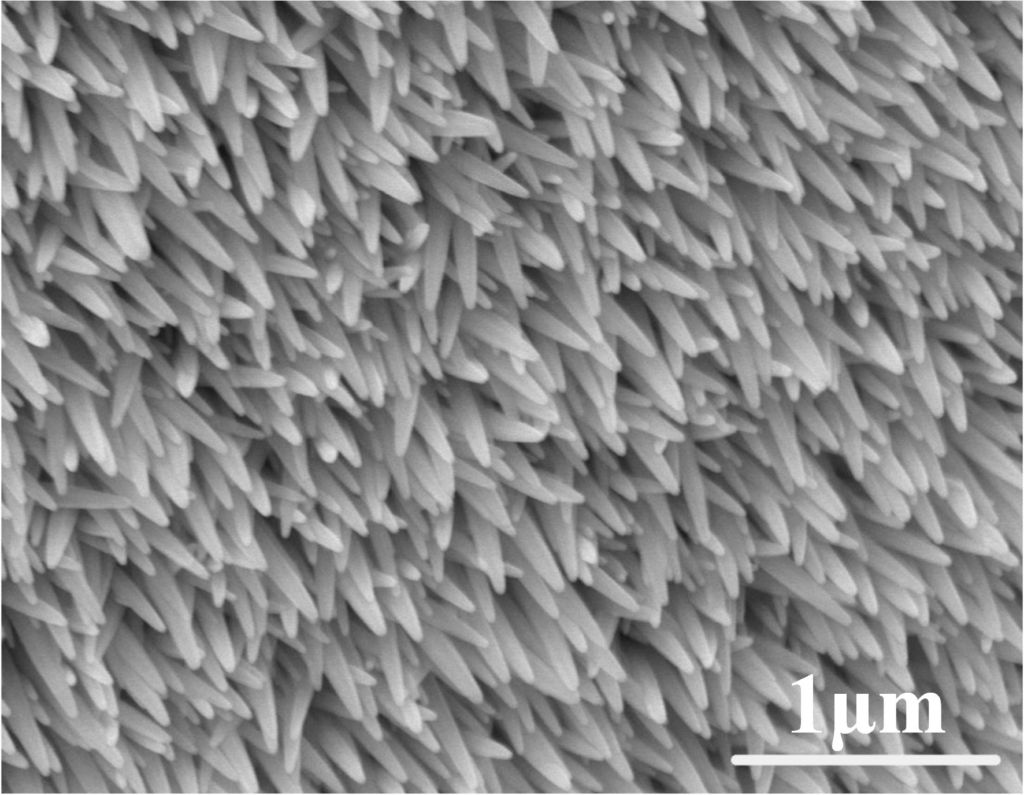

Finally, the team distributed nanostructures over the microlenses to attain performance-enhancing properties. Here they used a crystal growth method to deposit the structures onto the curved surface. The technique, developed by a separate research group in China, involves sputtering a seed layer of ZnO onto the surface of the microlenses and then immersing it in a solution that causes it to react and stimulate nanorod growth. The team thereby avoids nanostructure damage by forming the ZnO nanorods on the compound eye directly,

Nanostructures grown on the microlenses provide the eye with water-resistant and antireflective properties. Courtesy of Phys.org

Performance Results for the Complete Compound Eye

The researchers used a tungsten light source and a CCD camera to evaluate the optical performance of their artificial compound eye. The light source illuminated the eye, which was placed on a mechanical stage to adjust the angle of illumination. The CCD on the other side of the eye captured confocal images. Recorded intensity plots show that the eyes have high optical uniformity and produce very little distortion.

The team also used an optical microscope to compare performance of a single-lens to the compound eye. They found that the artificial eye exhibited superior focusing abilities while maintaining constant resolution with a changing illumination angle. Finally, they evaluated the effectiveness of the deposited nanostructures Measurements of contact angles and reflectivity show that the nano structured surface displayed high water repellence and low surface reflection, respectively.

The Takeaway

The research team at Xi’an Jiaotong University present an efficient, relatively low-cost method for fabricating artificial compound eyes. Their procedure is practical while also addressing the complexity of working with a curved surface. Tests show impressive optical performance and optimal hydrophobic and antireflective properties. The team believes their method could impact a diverse list of applications including surveillance imaging, light-field photography, and wide-angle communication.

For more detail on their technique for fabricating artificial compound eyes, find their study here. If you liked this article you might also like our latest article on Artificial Vision in Robotics.