Laser beams are notable for their small size and long range focusing capabilities. These qualities have been used in medicine for precision surgery, and in industry for precision cutting. However, change in the beam quality not perceptible to the eye can cause poor use of laser output. In these situations, beam profilers become an invaluable tool to constantly monitor the beam quality. It ensures that the device is operating at its highest level at any point in time. This article discusses some of the common beam parameters to look out for, the effect of beam quality for performance characteristics, and the different beam profiler types to use.

Beam characteristics

Laser beams can be analyzed at a single region to give a beam profile, or across regions in the direction of the beam propagation to give the beam characteristics.

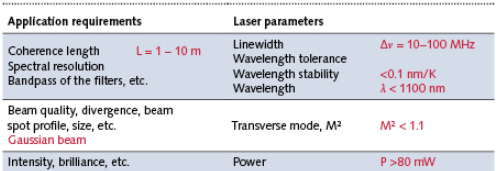

Common laser parameters to consider.

Beam profile and width: Ideal beam shapes are Gaussian or flat top types. Gaussian beams give a higher intensity at the center of the beam which can be used for nonlinear applications among others. Flat top beams are used where a uniform intensity is needed across a surface, such as in medical applications. The beam profile is monitored at a given plane in the direction of the beam propagation. The profiler must be moved to monitor different profiles along the beam. Additionally, multi-mode beams can be detected with multiple peaks in the profile.

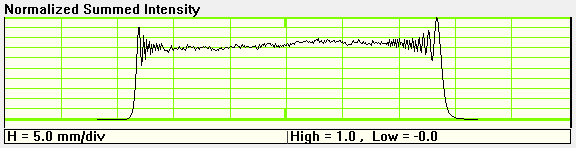

![]()

2D line laser beam profile (top) and a cross section along the long axis showing the nearly flat top intensity distribution. Image courtesy of DataRay Inc.

Beam jitter and astigmatism: Beam jitter refers to the random motion of the center of the beam. Astigmatism in this case refers to beams having different waist along horizontal and vertical directions. This is detected in the profiler camera by seeing that the beam width has a different minimum for horizontal and vertical profiles. Beam jitter can occur due to a number of minor factors in the lasing medium, and also from the optical bench setup. Jitter can affect proper alignment in systems, especially when trying to couple light efficiently into an optical fiber.

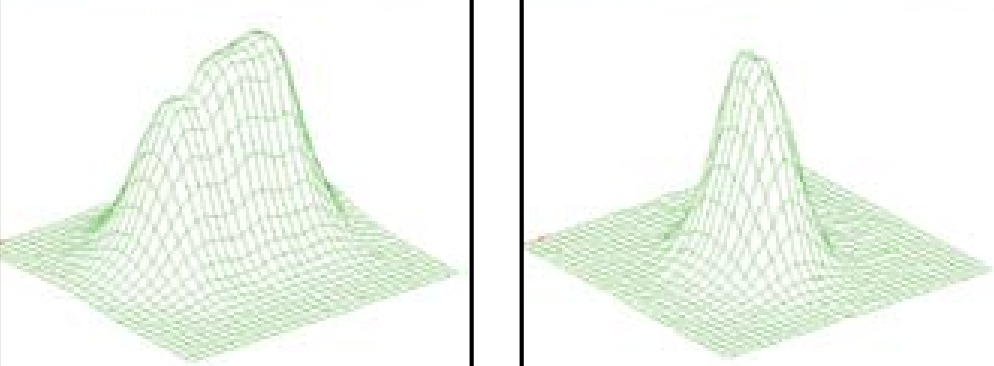

Left: Mismatched beam profile from a laser diode through a lens. Right: Corrected beam profile. Image courtesy of Ophir Opttronics.

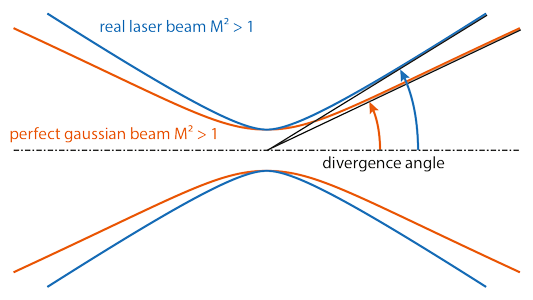

Propagation characteristics (M^2): The beam propagation product(BPP) is used to measure the nature of beam propagation. It is given as the product of the beam waist and the divergence angle. This is at a minimum for a Gaussian beam, with a value of wavelength/pi. The M^2 value is the ratio of the measured BPP to a Gaussian BPP. The M^2 value is independent of wavelength, and is a measure of how far the beam is from the ideal Gaussian beam characteristics. Thus keeping M^2 close to 1 is desired for good focusing.

Perfect and real beam M^2 comparison. All beams have M^2 greater than 1. Courtesy of SillOptics.

Beam quality measurement

Two main techniques are popular for beam profiling: camera methods, and knife-edge techniques (also known as “scanning slit”).

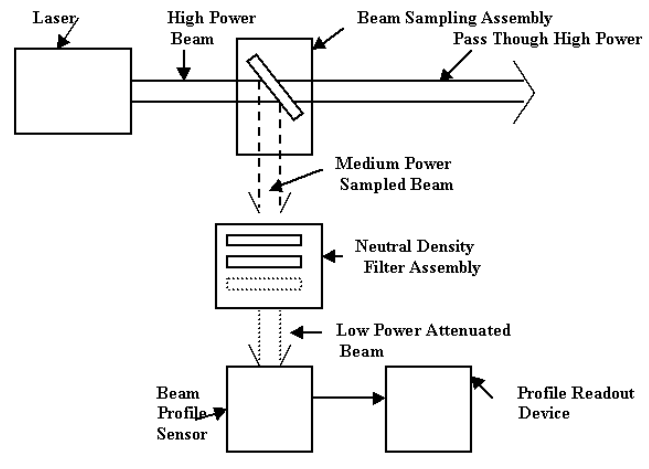

Measurement of beam quality by sampling the beam. Only a portion of the power is used for measurement. Courtesy of Spiricon.

Camera techniques: Camera techniques involve an array of pixels to record and display the beam profile. The advantage of this technique is that, it can display any beam profile which operates in the continuous or pulsed mode. The disadvantage is the size of the pixels limiting the measurement of the resolution of small beams to around tens of um. Another disadvantage is the saturation and damage threshold at high intensities.

Scanning slit laser beam profiler. Courtesy of DataRay Inc.

Knife-edge and Scanning edge techniques: Knife-edge techniques only measures a portion of the beam not blocked by the blade. Scanning edge scans the beam periodically to collect information. The advantage of this technique is the measurement of high intensities with very good SNR, and higher resolutions down to 0.1um. For best results, Gaussian beams are used, unlike in camera methods.

Special Applications

Non-linear optical effects rely on having high intensity at the center of Gaussian beams to increase efficiency of higher order processes. These intensities can be reached for instance in fiber optic cables with Gaussian beams. Efficient coupling of the Gaussian beam into the fiber is necessary to reach this. Beam profilers can be very useful here, by checking for beam jitter.

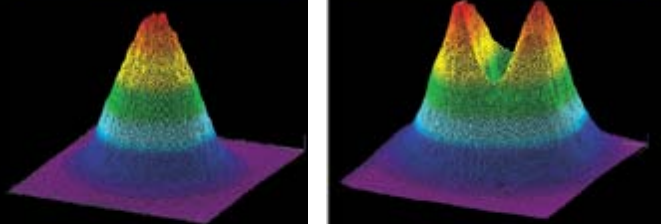

Left: Single mode lasing in Nd:YAG. Right: Multi-mode lasing causing a drop in the center intensity, noticeable at the output. Courtesy of Ophiropt.

Having a flat beam shape is necessary in photorefractive LASIK surgery. If there is a 50% tilt in the flat top, the correction in the eye can be 4 diopters ( diopter = 1/meter) to one side, and 2 diopters to the other side. This can cause the patient to end up with a non-correctable vision after the operation. Flat-top beams are crucial in this case, and constant monitoring with beam profilers is very important.

Laser beam profilers can be used in many applications to make sure you are getting the output beam profile and propagation that you need. Constantly monitoring the beam makes sure you are using the beam for your needs efficiently. Check out beam characterization solutions on FindLight for devices at different wavelengths to suit your needs.