A research team designed a new deformable mirror to optimize passively Q-switched laser performance. Courtesy of Flexible Optical.

Researchers at Tsinghua University look to optimize the performance of passively Q-switched lasers by confronting effects of thermal distortion. Their solution, a customized deformable mirror, proves to be a powerful fix that could greatly impact high-energy laser design.

Current Limits of Passively Q-Switched Lasers

Passively Q-switched (PQS) lasers use a saturable absorber to create short energetic pulses. While many Q-switched devices use an active modulator to create optical loss in a resonator, PQS defers to the absorber to build up pulses. This method is typically more cost-effective than active Q-switching and produces pulses with comparable repetition rates. PQS lasers are a common choice for applications such as micro-machining, remote sensing, and even novel methods of engine ignition.

Unfortunately, the performance of current PQS lasers is most limited by thermal effects such as thermal lensing. At high pumping powers, these effects can worsen beam quality, lower output power, and in some cases completely stop oscillation. Researchers have proposed a variety of deformable mirrors to compensate the thermal effect. Suggestions have included piezoelectric, micro-machined, and pneumatic actuation deformable mirrors. These devices, however, have their own limitations that often keep them from being successfully implemented into a PQS system. The options have been unable to address parameters of the PQS lasers including short cavity, small laser mode diameter, and large thermal mode.

In their paper published in the April edition of Optics Express, the Tsinghua research team presents a new deformable mirror to correct effects of thermal distortion in PQS lasers.

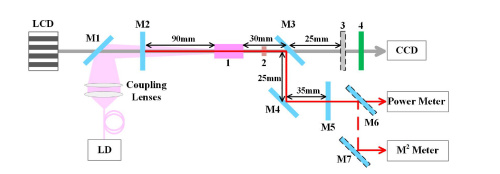

The research team designed and built their own PQS laser cavity for testing.Courtesy of OSA Publishing.

Determining Thermal Distortion

The picture above shows the schematic diagram of the team’s original PQS laser. The setup includes a fiber-coupled laser diode, a heating thermoelectric cooler (TEC) for diode temperature control, coupling lenses, a gain crystal, and 5 mirrors within the 180 mm cavity. Note that items 6 and 7 are prism-mirrors used only for measurement purposes. The PQS pulses are 50 nanoseconds and emit at 1064 nanometers.

The researchers observed the laser performance while increasing the pump current. Increasing pump current increases gain, therefore introducing severe thermal lensing effects. Average output power from the laser reaches maximum at pump current of 3.2 Amps. At this point, the output power begins to sharply decrease as the beam quality diminishes. The team then replaced the fourth mirror in the system with their custom designed deformable mirror to improve pulse performance at higher pumping currents.

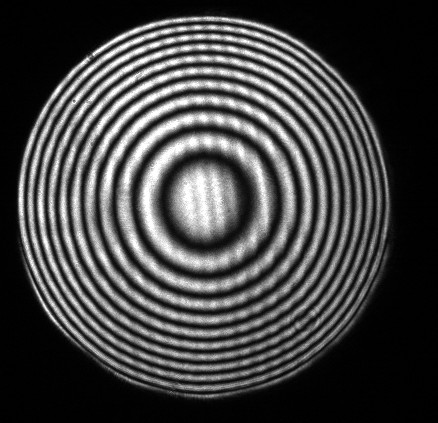

The team used a technique called active deflectrometry to measure the severity of thermal distortion in their system. This method includes a LCD, CCD camera, calibration board, filter, and a computer. Light from the PQS laser produces a distorted fringe pattern in X and Y directions as it emits through the gain medium with increasing pump current. This fringe pattern is then analyzed by a phase-shift algorithm to help reconstruct the wave front, resulting in a highly-precise account of thermal distortion.

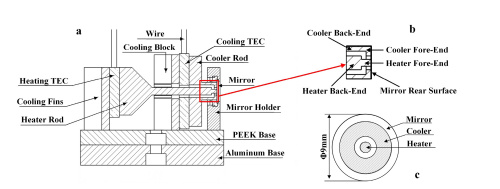

This image shows the heating and cooling units that adjust the rods responsible for deforming the mirror surface. Courtesy of OSA publishing

Deformable Mirror Schematic

The new deformable mirror consists of the mirror unit, a heating unit, a cooling unit, and a base. The mirror is compact to account for typically small PQS laser cavities. The heating and cooling units are each attached to one TEC so that heat will transfer to corresponding heating and cooling rods that are in contact with the mirror surface. The lengths of the rods change with applied heat, thus controlling the surface shape of the deformable mirror. The team designed their deformable mirror so that its target surface shape corrected distortion at 3.9 Amps, where thermal effects were most severe in their PQS laser testing.

Optimization of the beam quality at 3.9 A pump current using the deformable mirror. Courtesy of OSA publishing.

The Results

The team found significant improvements in beam quality and overall performance after replacing only a single mirror with their deformable mirror unit. Though the researchers modeled the mirror to offset distortion effects at the 3.9 Amps pumping current, the mirror proves to also improve performance at lower currents. The above figure shows just how much of an impact the deformable mirror makes on beam quality as the system stabilizes.

The custom-designed deformable mirror successfully compensates for thermal effects in a PQS laser. By simulating these effects to optimize mirror surface shape, the research team was able to eliminate the threat of severe distortion. The impressive improvement in beam quality and output power at high pump currents proves that the team has created a simple, cost-effective method for greatly improved PQS lasing.

For more information on this impactful deformable mirror, click here.