Introduction

Diffractive Optical Elements (DOEs) represent a pivotal advancement in the realm of optics and photonics, revolutionizing the way light is manipulated and harnessed. These intricate optical devices utilize the principles of diffraction, a fundamental phenomenon in wave optics, to control the propagation of light waves. The inception of DOEs traces back to the confluence of theoretical insights and technological progress, making their mark in diverse fields such as imaging, telecommunications, and spectroscopy.

At their core, DOEs are designed to mold light by exploiting the wave interference patterns that arise when light encounters structures on a scale comparable to its wavelength. Unlike traditional refractive or reflective elements, DOEs operate on the principle of phase modulation. Enabling the precise manipulation of light intensity and direction. This introduction sets the stage for delving into the underlying principles, applications, and intricacies of DOEs, highlighting their significance as powerful tools that have transcended the conventional boundaries of optical design and fabrication.

Today's blog post is brought to you by Connet Laser Technology - the leaders in fiber lasers and optical fiber technologies.

Principles of Diffraction

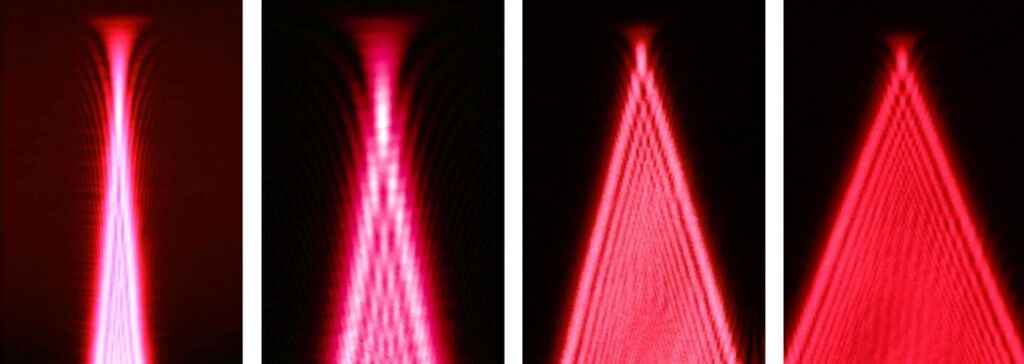

At the heart of DOEs lies the phenomenon of diffraction, a cornerstone of wave optics. Diffraction occurs when a wave encounters an obstacle or aperture, causing it to deviate from its expected path and form an intricate pattern– like the one above– of constructive and destructive interference. This behavior can be elucidated through the Huygens-Fresnel principle, which posits that every point on a wavefront acts as a source of secondary spherical waves. When these secondary waves superimpose, they generate complex interference patterns, resulting in the characteristic diffraction patterns observed in DOEs.

One of the fundamental manifestations of diffraction is observed in diffraction gratings. Where a periodic arrangement of slits or lines causes incident light to disperse into discrete orders. The key parameters influencing diffraction include the wavelength of the incident light, the size and shape of the diffracting elements, and the angle of incidence. Understanding these principles is crucial for the design and optimization of DOEs, as they enable engineers and researchers to precisely manipulate light to achieve desired outcomes. By harnessing the intricate wave behavior associated with diffraction, DOEs offer a platform to mold light with unprecedented precision, ushering in a new era of optical innovation across a spectrum of applications.

Basic Characteristics of DOEs

Diffractive Optical Elements stand apart from conventional optical components due to their distinctive characteristics, which arise from their mode of operation based on diffraction. Unlike refractive and reflective elements that rely on the interaction of light with material interfaces, DOEs manipulate light through the modulation of its phase. This unique approach grants DOEs the capability to finely control the intensity and direction of light propagation. One of the primary advantages of DOEs is their ability to produce complex intensity profiles, enabling tailored illumination patterns that are challenging to achieve with traditional optics. Moreover, DOEs excel in the creation of non-symmetric and non-circular beam shapes, which find applications in laser materials processing, lithography, and biomedical imaging.

However, DOEs are not without limitations. One of the main challenges lies in optimizing their efficiency, as a portion of incident light can be lost due to diffraction effects. Additionally, DOEs can be sensitive to variations in wavelength and incident angle, posing challenges in maintaining consistent performance across a range of operating conditions. Manufacturing precision also plays a pivotal role; minute errors in the fabrication of phase profiles or surface structures can significantly impact the final output. Despite these challenges, continuous advancements in design algorithms, fabrication techniques, and computational capabilities have mitigated many of these concerns.

The unique characteristics of DOEs have positioned them as indispensable tools in various fields. Their ability to tailor light patterns with unprecedented precision has paved the way for applications in laser-based manufacturing, optical trapping, and holography. Furthermore, DOEs have contributed to advancements in emerging technologies like augmented reality displays and compact optical communication systems. By pushing the boundaries of traditional optical design, Diffractive Optical Elements continue to play a pivotal role in shaping the future of optics and photonics.

Design and Fabrication

In the realm of optics, Diffractive Optical Elements (DOEs) stand out as powerful tools capable of manipulating light in intricate ways. Let’s look into the key considerations for their design, fabrication and engineering:

Design Principles

The following are the key design principles that employed in the design of diffractive optical elements.

- Iterative Algorithms: Through systematic algorithms, phase profiles of DOEs are optimized. This iterative approach ensures the desired output patterns are achieved.

- Fourier-based Methods: These methods help in the transformation of desired intensity distributions into relevant phase profiles.

- Phase Retrieval Techniques: When provided with intensity patterns, these techniques decipher the inherent phase information, bridging the gap between observation and theory.

- Practical Applications: The design methodologies empower the creation of DOEs for beam shaping, splitting, and generating complex intensity patterns.

Fabrication Techniques

Fabrication of DOEs relies on a few common techniques that have become the modern standards in manufacturing diffraction optics.

- Lithography: This process involves etching patterns onto a substrate. Using a spatial light modulator or a photoresist-coated substrate, patterns are exposed with precision.

- Pattern Transfer: Techniques like etching or ion milling are employed to transfer these patterns onto substrates, making them permanent.

- Electron-beam Lithography: For designs demanding higher resolution, electron-beam lithography allows the creation of sub-wavelength feature sizes, ensuring the fidelity of the final DOE.

Engineering Considerations

For a DOE to function optimally, several factors are taken into account during its design and fabrication:

- The desired diffraction pattern.

- The wavelength of the incident light.

- The angle at which light is incident.

A primary objective is to achieve maximum diffraction efficiency, ensuring efficient energy utilization and stray light minimization.

Types of DOEs

Diffractive Optical Elements encompass a diverse array of designs tailored to specific light manipulation tasks. These designs leverage the principles of diffraction to mold light in intricate ways, offering a versatile toolkit for various applications.

- Beam shapers and homogenizers are designed to transform irregular or non-uniform beams into smooth, uniform intensity distributions. This is crucial in applications like laser materials processing, where even energy delivery is paramount.

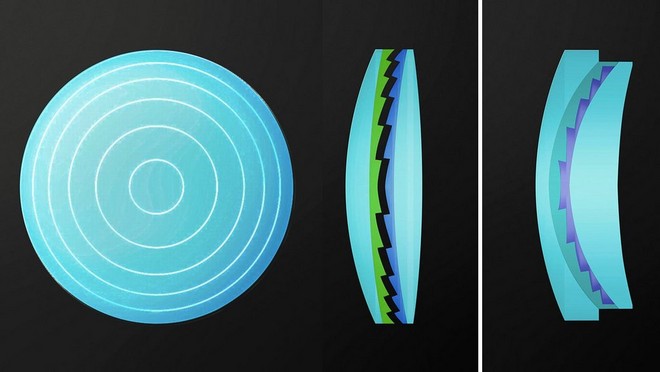

- Diffractive lenses and axicons replace traditional refractive lenses, offering benefits such as lightweight and compact designs. Axicons, in particular, generate a unique Bessel beam profile with applications in optical tweezers and laser drilling.

- Holographic optical elements encode complex phase information to replicate the wavefronts of desired optical systems. These are main components of head-up displays, holographic storage, and optical interconnects.

- Gratings, another class of DOEs, find application in spectral dispersion, separating light into its component wavelengths for spectroscopy and hyperspectral imaging.

- Beam splitters and combiners built upon DOEs can split or combine multiple beams with high precision. This is essential for interferometry and parallel processing applications.

- Binary phase DOEs consist of discrete phase levels, simplifying fabrication, while continuous phase DOEs offer greater flexibility but demand more complex manufacturing processes.

The applications are boundless. DOEs enable the creation of dynamic 3D displays, optimize light delivery in medical devices, and enhance the efficiency of solar concentrators.

Each type of DOE requires a specific design approach and fabrication method, tailored to its intended function. While DOEs present certain challenges their adaptability and unique capabilities make them indispensable tools for modern optics and photonics. As researchers and engineers continue to explore novel applications and refine fabrication techniques, the versatility of Diffractive Optical Elements will undoubtedly continue to expand, shaping the future of optical innovation.

Applications of Diffractive Optical Elements

DOEs have found a multitude of applications across a wide spectrum of scientific, industrial, and technological domains, revolutionizing the way light is harnessed and manipulated.

- In laser beam shaping, DOEs play a pivotal role in transforming Gaussian beams into tailored intensity profiles. This finds use in materials processing, enabling precise cutting, welding, and engraving in industries ranging from automotive to electronics.

- Imaging and microscopy benefit from DOEs that create structured illumination patterns, enhancing resolution beyond the diffraction limit. Fluorescence microscopy and super-resolution imaging, with applications in cell biology and medical diagnostics, owe their advancements to DOEs. Apart from more scientific applications, they offer unparalleled quality for personal photography, as illustrated below via a Canon DOE.

- Optical trapping and manipulation leverage DOEs to create multiple optical traps for precise manipulation of micro- and nano-scale objects. This is essential in fields like biophysics and nanotechnology,

- The display industry has embraced DOEs in holographic displays and head-up displays, introducing immersive 3D experiences and enhancing augmented reality applications.

- Spectroscopy and hyperspectral imaging capitalize on DOEs for spectral dispersion, enabling detailed analysis of complex materials and chemical compositions.

- Optical communication systems benefit from DOEs as compact and efficient components for beam steering, shaping, and combining, enhancing data transmission efficiency and enabling novel free-space optical communication concepts.

- DOEs have even found their way into space exploration, optimizing the performance of spaceborne instruments and telescopes.

- In the medical field, DOEs benefit ophthalmic devices for vision correction, as well as in diagnostic and therapeutic lasers.

As DOEs continue to evolve, their applications will undoubtedly expand. Research is ongoing to integrate DOEs into quantum optics systems, enabling novel advancements in quantum communication and computing.

The breadth and depth of applications underscore the profound impact of Diffractive Optical Elements across numerous scientific and technological domains. By providing unprecedented control over light, DOEs have not only enhanced existing fields but also paved the way for entirely new avenues of exploration and innovation.

Challenges and Future Directions

While Diffractive Optical Elements have revolutionized optical design and manipulation, they are not without challenges and ongoing areas of exploration. Addressing these challenges is pivotal for unlocking their full potential and expanding their applications.

One of the primary challenges in designing DOEs is optimizing their efficiency. Unwanted diffraction orders can lead to energy losses, impacting the overall performance of the optical system. Researchers are constantly exploring novel approaches to enhance efficiency, including advanced optimization algorithms and innovative phase modulation techniques.

Manufacturing precision is another critical aspect. Even small errors in the fabrication process can lead to deviations in the intended phase profiles. Ultimately affecting the final output of the DOE. Advancements in nanofabrication technologies are helping to overcome this challenge, enabling the creation of DOEs with sub-wavelength features and intricate phase profiles.

DOEs are often sensitive to variations in wavelength and incident angle. This sensitivity can limit their performance under different operating conditions. Future research may focus on developing DOEs that are more robust to these variations, making them more versatile and reliable in real-world applications.

As DOEs continue to find new applications, there’s a growing need for more comprehensive design and simulation tools. Researchers are working on developing software and algorithms that allow for the accurate modeling of DOEs in various scenarios, facilitating the design process and reducing the need for extensive trial-and-error experimentation.

Moreover, the integration of DOEs with other optical and photonic technologies is an area of active exploration. Combining DOEs with metasurfaces, plasmonics, and adaptive optics can potentially lead to new functionalities and enhanced performance.

The future directions for DOEs are promising. Research is pushing the boundaries of their capabilities, from achieving ultra-high efficiencies to expanding their applications in emerging fields like quantum optics. As the challenges are gradually overcome and new innovations emerge, Diffractive Optical Elements are poised to continue their journey as essential tools for shaping the future of optics and photonics.

Comparison with Other Optical Elements

DOEs stand as a distinct category within the realm of optical components. They offer unique advantages and trade-offs when compared to traditional refractive and reflective elements.

Refractive optics utilize the bending of light through materials with varying refractive indices. While simple to design and manufacture, they are limited by chromatic aberrations, limiting their effectiveness in broadband applications. Reflective optics, on the other hand, use surface mirrors to manipulate light. They suffer from fewer chromatic aberrations but can be bulky and complex, particularly for applications requiring intricate beam shaping.

DOEs, however, circumvent some of these limitations. They can correct for chromatic aberrations through precise phase manipulation, facilitating multi-wavelength applications. Moreover, DOEs are inherently lightweight and compact, making them valuable in space-constrained environments.

However, DOEs are not without challenges. As we mentioned above, the efficiency is a prime concern, as a significant portion of incident light is often lost to unwanted diffraction orders. Moreover, DOEs are often sensitive to variations in incident angle and wavelength, making them less tolerant to changes in operating conditions compared to refractive optics.

The choice between DOEs and traditional optics depends on the specific application. For tasks demanding complex intensity distributions or non-traditional beam shapes, DOEs offer unparalleled capabilities. Traditional optics, while simpler in some aspects, might struggle to achieve the same level of precision and versatility.

In many scenarios, hybrid systems that combine DOEs with refractive or reflective elements are preferable. This approach capitalizes on the strengths of each type, mitigating their respective weaknesses. Such systems find use in laser systems, displays, and lithography equipment, where precise control over light distribution is crucial.

Ultimately, the decision between DOEs and traditional optics hinges on the requirements of the application. Taking into account factors such as efficiency, size constraints, and desired performance characteristics. As DOEs continue to advance and their design and fabrication techniques improve, their position in optical system design will become even more prominent, challenging and complementing traditional optical elements in innovative ways.

Conclusion

Diffractive Optical Elements have emerged as a cornerstone of modern optics and photonics, reshaping the landscape of light manipulation and optical design. By harnessing the intricate phenomenon of diffraction, DOEs offer a revolutionary approach to controlling light, enabling applications that were once deemed unattainable with traditional optical elements.

From their inception, DOEs have transcended the boundaries of conventional optics. They have proven to be indispensable tools in diverse fields, ranging from laser beam shaping for industrial processes to enabling groundbreaking advances in microscopy and imaging. DOEs have also penetrated emerging technologies like augmented reality displays and quantum optics systems. This is where their unique capabilities find new dimensions of utility.

While DOEs come with their own set of challenges, including efficiency optimization and sensitivity to operating conditions, ongoing research, and technological advancements continue to mitigate these limitations. Innovations in design algorithms, fabrication techniques, and computational resources are propelling DOEs into new realms of possibility.

As the realm of optical design and fabrication continues to evolve, DOEs will remain at the forefront of innovation. Their ability to sculpt light with unprecedented precision and flexibility offers a tantalizing array of opportunities across scientific, industrial, and technological domains. The synergy between theoretical insights and engineering prowess is shaping the future of optics. DOEs hold the promise of pushing boundaries of what’s possible and unlocking solutions to challenges that were once considered insurmountable.

In this ever-evolving landscape, the journey of DOEs is far from over. As researchers and engineers delve deeper into their potential, we can anticipate that DOEs will continue to illuminate our understanding of light, forging new paths for technological advancements and reshaping the course of scientific discovery.

Interested in purchasing Diffractive Optical Elements? You can start your comparison shopping here at FindLight.