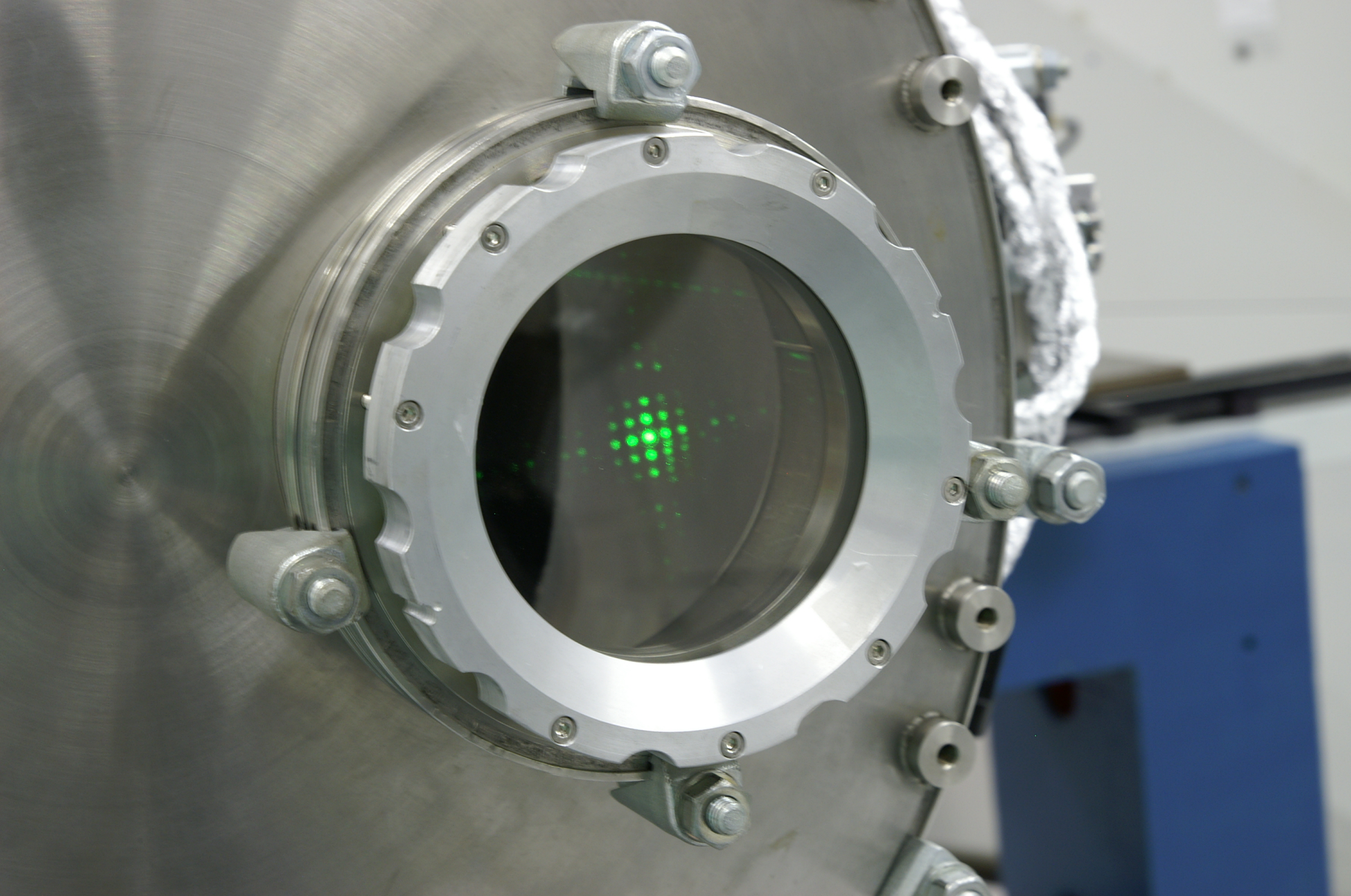

The compactness and efficiency of DPSS laser systems provide a powerful tool for many different scientific applications. Courtesy of Tom Zagwodzki.

Basics of Operation

There are many different types of lasers available in todays photonics market, however, Diode Pumped Solid State (DPSS) laser systems are a reliable and widely-used technology. Simply speaking, a laser is basically a machine that forces billions of atoms to pump out great amounts of light particles, or photons, in a way that forms an extremely concentrated beam. For example, where a flashlight beam expands as the distance from the source increases, laser beams will stay relatively constant.

Aside from systems such as semiconductor lasers and fiber lasers, many types of lasers require a gain medium, or a load of atoms that can be stimulated to release photons. This medium can be either a solid, liquid, or gas. In the case of DPSS lasers, this medium is a solid, hence the name “solid-state.” The solid gain medium in a DPSS laser typically involves crystals or glasses altered with rare earth metal ions, transition metal ions or semiconductor lasers. Additionally, lasers require a source, like a lamp or another laser, to stimulate these atoms for a process called pumping. DPSS laser systems are categorized as “diode-pumped” because they utilize a laser diode as their atom stimulation source.

By stimulating the medium, atoms absorb energy as their electrons jump to a higher energy level. As the electrons return to their original energy level, the atoms give off light through the process of spontaneous emission. Sometimes, photons excite an already stimulated atom. This results in an increase of photons emitted from the atom. This process, called stimulated emission, allows for the amplification of light. The laser’s partial mirror permits only some of these photons to escape, thus producing a concentrated beam of powerful light.

Advantages Compared to Other Lasers

The laser has come a long way since it was invented almost 60 years ago. For example, a centimeter-long DPSS lasers can produce over 60 watts of power, while still maintaining excellent efficiency. While many types of lasers exist, DPSS lasers hold several different advantages over other laser types. This is mainly due to their high power density, excellent beam quality, and high efficiency.

In comparison to lasers utilizing other gain mediums, such as gas, solid-state lasers offer compact size, allowing for easy implementation into standing infrastructure. Whereas gas lasers require systems to be assembled around the laser source itself, solid-state lasers require far less space and are much more flexible in placement. Additionally, energy consumption of solid-state lasers tends to be considerably cheaper than that of gas, resulting in lower operating costs.

DPSS lasers offer high beam quality, compactness, and high energy efficiency. Courtesy of HiLASE.

Contrasting from another type of laser system, laser diodes, DPSS lasers generally have a higher beam quality. Furthermore, they have the ability to reach very high powers while still maintaining decent beam quality. In contrast, laser diodes can only reach a few hundred milliwatts before losing quality. In addition, diode lasers tend to have a larger beam diameter and divergence, making them less desirable for certain applications.

Other key advantages of DPSS lasers worth mentioning are their high electrical to optical conversion efficiency, stable output of laser power, low maintenance, long diode lifetime of up to 10,000 hours, and compactness.

Applications

Due to characteristics like superior efficiency and highly concentrated light beams, DPSS lasers find use in a wide variety of industrial, military, aerospace, and research applications.

Industrial settings commonly use DPSS lasers for tasks such as alignment and position, cutting, drilling, welding, laser trimming, and more. The DPSS laser has excellent performance when paired with materials including plastics, metals, and some types of ceramics. The latest advancements in DPSS laser systems offer advantages including low power consumption, minimal heat generation, compact packaging, and reliability that meet the needs of today’s manufacturing processes.

The military finds applications for DPSS lasers in communication, defensive countermeasures, long range audio spying, target designation, and weapons research. One interesting example is the AN/AQS-20A Mine Hunting System, which utilizes DPSS lasers as a means to detect and classify mines from the sea floor to the surface. This military laser system is towed underwater from a helicopter and provides real-time, sonar images to operators for observing and recording mine-like objects.

NASA utilizes DPSS lasers to determine the distance of satellites, position of spacecrafts, and improve knowledge on lunar characteristics. Courtesy of NASA.

Another example that showcases just how powerful DPSS laser systems can be is the Lunar Reconnaissance Orbiter (LRO) Satellite Ranging. One goal of LRO is to create accurate maps of lunar surfaces in preparation for NASA’s return to the moon. The ground station, Goddard’s Laser Ranging Facility, incorporates DPSS lasers to determine the range of the satellite and spacecraft position. This technology is currently improving the knowledge of the moon’s orientation and gravity, which is a crucial component of understanding the moon’s structure and how to navigate it.

Market Growth

Thanks to recent advancements in technology and manufacturing, the DPSS laser has slightly decreased in cost and has become more commercially available to growing industries. Some experts predict that the ultrafast laser industry, which includes DPSS lasers, will reach $7.1 billion by 2021. This comes as no surprise as these lasers continue to offer benefits in research, material processing, and health care.

Experts predict that the ultrafast laser, which includes DPSS lasers, will continue to grow for years to come. Courtesy of Laser Lines.

According to one report, one of the most significant reasons behind this prediction stems from the increased market for laser cutting machines. The rapid industrialization of countries like India and China will soon require advanced laser cutting machines in years to come. Additionally, recent applications in the health care sector call for the increased use of laser cutting machines for micro-cutting processes. Lastly, manufacturing in many industries, including automotive, aerospace and defense, continue to require high-quality fabrication of metal parts. The increasing acceptance for innovations made in DPSS and laser cutting technologies contributes to the overall projected growth of the ultrafast laser industry.