Amidst the dynamic landscape of laser technology, dye lasers emerge as a beacon of innovation and adaptability. Renowned for their ability to produce a wide spectrum of light through tunable wavelengths, these lasers have cemented their role as critical instruments in a myriad of scientific, industrial, and medical fields.

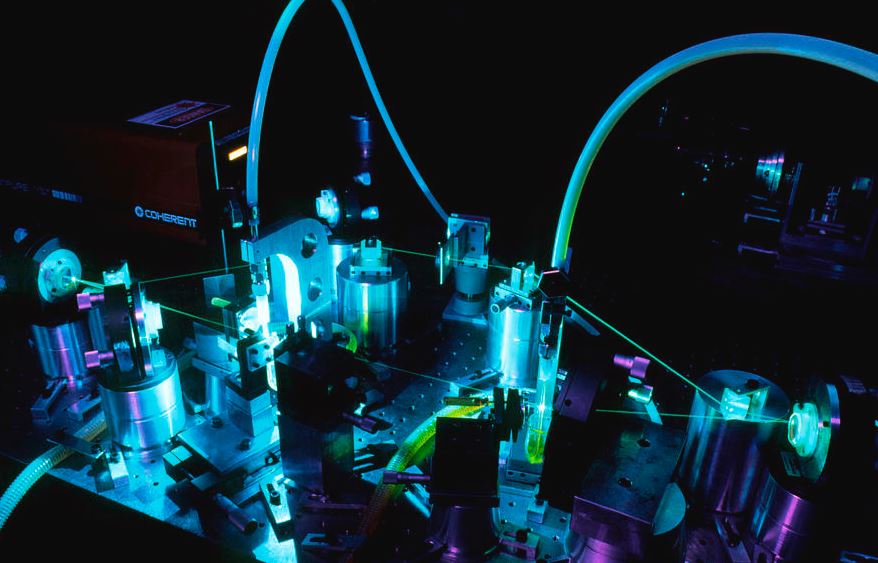

Peek inside the world of dye lasers: an operational dye laser reveals its core components and beams. Witness the fusion of precision engineering and advanced laser technology in action. Photo courtesy of fineartamerica.com

What We Cover: This guide serves as your comprehensive reference on dye lasers, addressing every facet from the basic principles to the cutting-edge applications. We dissect the technical aspects, elucidate the operational mechanics, and navigate through the diverse applications where dye lasers make a significant impact. Additionally, for those considering integrating dye lasers in their work, we provide practical insights and considerations for purchasing and implementation.

1. Introduction to Dye Lasers

Background: Since their inception in the 1960s, dye lasers have utilized the lasing properties of organic dyes to generate light, revolutionizing the way we approach light-based technology. Their versatility in wavelength generation has not only sparked considerable interest but has also propelled forward a wide array of research and technological advancements.

Scope of the Guide: This guide is meticulously crafted to demystify the world of dye lasers for engineers, scientists, and technologists. We explore the underlying principles, the sophisticated design, and the diverse applications that make dye lasers a cornerstone in contemporary technology. For those considering the integration of dye lasers into their work, this guide also provides invaluable insights and purchasing advice.

Importance: In an era where precision and customization in light sources are paramount, mastering dye lasers is essential. Their applications range from detailed spectroscopy to intricate holography, and even into critical medical diagnostics. This guide is designed to equip you with the knowledge to navigate these areas confidently and to inspire innovation in your field.

2. Basic Principles

Fundamentals of Laser Technology: Laser operation hinges on optical amplification via stimulated emission. The emitted light, coherent and monochromatic, typically exhibits characteristics like a narrow bandwidth (usually within 0.1 nm) and high beam collimation, producing intense, focused light.

Properties of Dye Lasers: Dye lasers are unique for their broad tunability, covering wavelengths from about 360 nm (ultraviolet) to 900 nm (near-infrared). They feature a wide gain bandwidth, allowing for fine-tuning across a spectrum, and can produce high peak power outputs, essential for applications requiring intense, short bursts of light.

Working Principle of Dye Lasers: In dye lasers, a liquid dye medium (e.g., Rhodamine 6G, with a tunable range of 570-650 nm) is excited, typically by a flashlamp or another laser (like a Nd:YAG laser at 532 nm). This excitation propels dye molecules into an excited state, from which they emit photons to produce a coherent output.

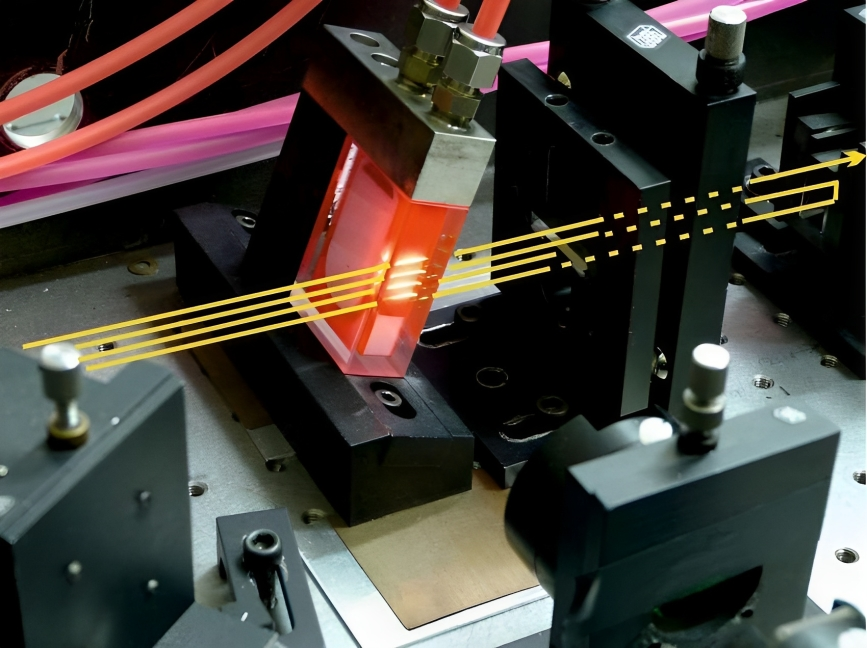

Inside the Heart of a Dye Laser: A detailed view of a dye cell, where science meets precision. Follow the journey of light, traced in this close-up, revealing the complexity and elegance of dye laser technology.

Laser Medium: The laser medium comprises dyes like Coumarin, which operates in the 450-500 nm range, and Stilbene, effective in the 400-450 nm region. These dyes, dissolved in solvents like ethanol or methanol, determine the laser’s emission wavelength and efficiency.

Pumping Mechanism: Different pumping sources impact dye laser performance. Flashlamps, with a broad emission spectrum, provide extensive wavelength tunability. In contrast, laser pumping, such as with an argon-ion laser, offers more precise control over the excitation wavelength, optimizing the output for specific applications.

Optical Resonator: The resonator’s design, including mirror and grating configurations, is key for wavelength control. For instance, a Littrow configuration, using a diffraction grating at around 1200 lines/mm, can precisely select wavelengths within the dye’s emission range, offering tunability and efficient output.

3. Types of Dye Lasers and Their Characteristics

Overview: Dye lasers, classified into two primary types based on their operational mode – Continuous Wave (CW) and Pulsed – cater to a wide range of applications. Each type boasts unique features suited to specific requirements in scientific and industrial domains.

Continuous Wave (CW) Dye Lasers:

CW dye lasers deliver a consistent, uninterrupted laser beam, making them invaluable in scenarios where beam stability and continuous operation are paramount.

- Operational Mechanism: These lasers typically utilize a dye solution like Rhodamine B, enabling a stable output in the 580-600 nm range. A continuous pumping source, such as an argon-ion laser, maintains the dye in an excited state to ensure steady lasing.

- Applications: Their precise and stable beam output is critical in high-resolution spectroscopy, where even minor fluctuations can affect measurement accuracy. CW dye lasers are also extensively used in atomic cooling and trapping, where maintaining specific wavelength and beam intensity is crucial.

- Advantages: The key advantage lies in their ability to produce a uniform output with minimal fluctuations, essential for experiments requiring long-term stability and precision.

Pulsed Dye Lasers:

Pulsed dye lasers are designed to emit laser light in short, high-intensity bursts, making them suitable for applications that require high peak power.

- Operational Mechanism: These lasers often employ dyes like Coumarin, which are efficient in producing short-wavelength pulses (e.g., 450-500 nm range). Pulsing mechanisms, such as Q-switching or mode-locking, allow for the generation of pulses typically ranging from 5 to 20 nanoseconds.

- Applications: Pulsed dye lasers are fundamental in time-resolved spectroscopy, where they enable the study of rapid physical and chemical processes. They are also critical in laser-induced fluorescence techniques and photodynamic therapy, where controlled, intense bursts of light are necessary for precision treatments.

- Advantages: The primary benefit of pulsed dye lasers is their capacity to deliver high-energy pulses, allowing for detailed analysis and manipulation of fast-paced reactions and processes.

4. Dye Laser Components

The following are the key components of a typical dye laser:

Laser Dye and Solvents

Common Dyes and Their Properties: Dye lasers utilize a range of organic dyes, each offering unique lasing properties. For instance, Rhodamine 6G, a popular choice, operates efficiently in the 570-650 nm range, ideal for green to yellow-orange outputs. Coumarin dyes cover the blue to green spectrum (450-510 nm), while Stilbene dyes are used for near-ultraviolet wavelengths (around 400 nm). Each dye’s photostability, quantum efficiency, and absorption spectrum are crucial in determining its suitability for specific applications.

Colors of Innovation: A vivid display of laser dye solutions, each cuvette a window into the diverse world of dye laser technology. Image courtesy of PhysicsOpenLab.

Solvent Selection Criteria: The choice of solvent impacts the dye’s solubility, fluorescence lifetime, and lasing wavelength. Common solvents include ethanol, methanol, and ethylene glycol. The key factors in solvent selection are the dye-solvent compatibility, the impact on the dye’s photophysical properties, and the operational temperature range of the laser system.

Pump Sources

Flashlamps: Flashlamps, typically xenon or krypton arc lamps, provide broad-spectrum pumping, suitable for wide tunability of the dye laser. They are favored for their high energy output, making them suitable for high-power, pulsed dye lasers. However, their efficiency can be lower compared to other pumping sources.

Laser Pumps: Laser pumps, such as argon-ion or frequency-doubled Nd:YAG lasers, offer more precise and efficient pumping. They allow for better control over the excitation wavelength, leading to higher efficiency and stability in dye laser operation, especially beneficial for continuous-wave dye lasers.

Optical Components

Mirrors: Mirrors in dye lasers are critical for reflecting and directing the laser beam. High-reflectance mirrors are used at specific wavelengths to ensure efficient light amplification within the laser cavity. These mirrors must withstand high-intensity light without degrading.

Diffraction Gratings: Diffraction gratings serve as wavelength selectors, crucial for tuning the output wavelength of the dye laser. By adjusting the grating angle, different wavelengths can be selectively amplified, providing the dye laser’s characteristic tunability.

Wavelength Selectors: Besides diffraction gratings, other wavelength-selective components like prisms or birefringent filters are used to refine the laser output. These components allow for precise control over the emitted wavelength, essential for applications requiring specific laser lines.

Cooling Systems

Dye lasers generate significant heat, necessitating efficient cooling systems. Water or air-cooled systems are commonly employed to maintain operational stability and prevent thermal damage to the dye and optical components. The choice of cooling system depends on the laser’s power output and operational duty cycle.

5. Design and Fabrication

In dye lasers, the art and science of design and fabrication are central to achieving excellence in performance. In this section, we delve into the complex process of constructing a dye laser, where precision in every component is key to its success. From the initial design stages to the meticulous assembly, we discuss the critical considerations and techniques that shape a dye laser’s functionality and effectiveness. We also emphasize essential safety measures, ensuring not just the optimal operation of the laser but also safeguarding the well-being of its operators. This exploration is not merely about assembling a device; it’s about crafting a precision tool that rises to the challenges of advanced scientific and technological applications.

Design Considerations

Wavelength Tunability: One of the primary design objectives for dye lasers is achieving a broad range of wavelength tunability. This is accomplished by selecting appropriate dye types and optical components like diffraction gratings and wavelength selectors. The design must facilitate easy adjustment of these components to enable smooth tuning across the desired wavelength spectrum.

Power Output: The power output of a dye laser is a critical parameter, especially for applications requiring high-intensity light. Designers must balance between the dye concentration, pump power, and optical cavity design to optimize output power while preventing dye degradation and ensuring the longevity of the laser system.

Beam Quality: Beam quality, encompassing factors like beam divergence, coherence length, and spatial uniformity, is paramount. The design must ensure minimal optical aberrations and high beam stability. This involves precise alignment of optical components, high-quality mirrors, and careful design of the laser cavity to produce a clean, stable laser output.

Fabrication Techniques

Fabrication of dye lasers involves intricate processes to assemble various components like the dye cell, pumping system, and optical resonators. The use of materials that resist corrosion by the dye solvents and that can withstand high thermal loads is essential. Precision in the alignment of optical components is crucial for optimal performance, often requiring specialized equipment and expertise.

Safety Measures and Precautions

Dye Handling: Many laser dyes can be toxic or carcinogenic, and solvents often pose fire hazards. Safe handling procedures, including the use of gloves, protective eyewear, and proper ventilation, are essential.

Laser Safety: Given the high intensities and potential for eye damage, adhering to laser safety standards is critical. This includes using protective eyewear specific to the laser’s wavelength, securing the laser area, and training users in safety protocols.

Heat Management: Dye lasers generate significant heat, especially in high-power or continuous-wave operations. Incorporating efficient cooling systems and thermal management strategies is vital to prevent overheating and to ensure stable laser operation.

6. Applications of Dye Lasers

Dye lasers find numerous applications from scientific to industrial uses. Let’s look into some of the most common applications of dye lasers:

Scientific Research: Dye lasers play a crucial role in advanced scientific research due to their tunable wavelength capabilities. They are extensively used in areas like atomic and molecular spectroscopy for precise measurements of atomic and molecular energy levels. In quantum optics, dye lasers facilitate the study of quantum phenomena by providing highly coherent and controlled light sources.

Medical Applications: In the medical field, dye lasers have transformative applications. They are particularly effective in dermatology for treating skin conditions like port-wine stains and other vascular lesions, as their tunable wavelengths allow for targeted treatment of affected areas without damaging surrounding tissues. In ophthalmology, dye lasers are used for selective photocoagulation in treating retinal disorders.

Industrial Uses: In industry, dye lasers serve in various roles, from materials processing to quality control. Their ability to produce a range of wavelengths makes them suitable for tasks like precision cutting and welding of different materials. Additionally, dye lasers are employed in the semiconductor industry for photolithography, where they enable the creation of intricate patterns on semiconductor wafers.

Spectroscopy and Metrology: Dye lasers are invaluable in spectroscopy and metrology, providing essential tools for chemical analysis and measurement. They are used in Raman spectroscopy for studying molecular vibrations, rotations, and other low-frequency modes in a system. In metrology, their precise wavelength control aids in the calibration of measurement devices and in the determination of physical constants.

Telecommunications: In the field of telecommunications, dye lasers have a niche yet significant role. Their tunable nature allows for flexibility in optical communication systems, particularly in the testing and development of new communication technologies. They are used for aligning and testing fiber optic components, and in some cases, as tunable light sources in research and development of optical networks.

7. Performance and Optimization

As we venture into the operation of dye lasers, understanding and mastering their performance and optimization becomes paramount. in this section we shed light on the intricate balance between efficiency, output power, wavelength stability, and the longevity of dye solutions – elements that are foundational to the operational excellence of dye lasers. We delve into the nuances of optimizing these facets, discussing how even minor adjustments can lead to significant improvements in performance. From fine-tuning the laser components to implementing advanced techniques for enhancing efficiency and stability, this part of the guide is dedicated to empowering users with the knowledge to not only operate dye lasers at their peak but also to extend their operational lifespan. Here, we unravel the best practices that underpin the high-performance functioning of dye lasers.

Efficiency and Output Power

Maximizing the efficiency and output power of a dye laser is fundamental for its effective operation. Efficiency largely depends on the match between the pump source’s emission spectrum and the dye’s absorption spectrum. Optimizing the dye concentration and ensuring proper alignment and focusing of the pump beam are key to enhancing output power. Additionally, minimizing losses in the optical resonator through high-quality mirrors and coatings can significantly boost overall efficiency.

Wavelength Stability

Wavelength stability is crucial for applications requiring consistent and precise light outputs. Factors affecting stability include environmental conditions like temperature and mechanical vibrations, as well as the quality of the dye and solvent. Employing stable mechanical setups, temperature control systems, and high-purity, stable dyes and solvents are effective strategies for maintaining consistent wavelength output.

Lifespan of Dyes

The operational lifespan of laser dyes is a critical consideration, as it impacts both performance and maintenance costs. Photodegradation of dyes, often accelerated by higher laser powers and prolonged usage, is the primary cause of reduced lifespan. Selecting dyes with high photostability, using optimal dye concentrations, and implementing efficient cooling systems can extend the lifespan of the dye. Regularly monitoring and replacing the dye solution when signs of degradation appear is also essential for sustained performance.

Techniques for Performance Enhancement

There are several techniques to enhance the overall performance of dye lasers:

- Pump Source Optimization: Selecting the most suitable pump source and optimizing its alignment can greatly improve efficiency.

- Resonator Design Tweaks: Adjusting the resonator design, such as modifying mirror placements and incorporating wavelength-specific coatings, can enhance beam quality and output power.

- Dye Circulation Systems: Implementing advanced dye circulation systems can help maintain dye stability and reduce thermal effects, leading to improved performance and longer dye life.

- Wavefront Correction: Employing adaptive optics or wavefront correction techniques can rectify beam aberrations, improving beam quality and efficiency.

8. Maintenance and Troubleshooting of Dye Lasers

Efficient maintenance and adept troubleshooting are vital for the seamless operation and longevity of dye lasers. In this section, we focus on the essential practices that ensure dye lasers function at their optimal capacity. We’ll cover regular maintenance routines, from cleaning to checks of critical components, and dive into troubleshooting common issues that can arise in the course of operation. Additionally, we address the crucial aspects of replacing and safely disposing of dye solutions, emphasizing both user safety and environmental responsibility. This guidance is designed to equip users with the knowledge to effectively maintain their dye laser systems and quickly resolve any operational challenges they encounter.

Regular Maintenance Practices

Routine Checks and Cleaning: Regular maintenance is key to ensuring the long-term performance of dye lasers. This includes routine checks of the laser medium, optical components, and pump source. Regular cleaning of the laser cavity, mirrors, and optical elements is crucial to prevent dust accumulation, which can degrade laser performance.

Dye Solution Maintenance: Monitoring the dye solution’s condition is essential. This involves checking for signs of degradation, such as color changes or decreased efficiency, and ensuring the dye concentration remains optimal for lasing.

Cooling System Upkeep: Maintaining the cooling system, whether it’s water or air-based, is critical. Regular checks for leaks, ensuring proper coolant flow, and cleaning cooling components help prevent overheating and potential damage to the laser system.

Common Issues and Solutions

Reduced Laser Output: A common issue is a decrease in laser output, often caused by dye degradation or misalignment of optical components. Replacing the dye solution and realigning mirrors and gratings can resolve this.

Fluctuating Wavelength Output: If the laser’s wavelength output fluctuates, it could be due to temperature variations or mechanical instability. Implementing better environmental controls and ensuring stable mechanical setup can help stabilize the output.

Beam Quality Degradation: Degraded beam quality might result from dirty or damaged optical components. Regular cleaning and, if necessary, replacement of these components can restore beam quality.

Replacement and Disposal of Dye Solutions

Safe Replacement Procedures: When replacing dye solutions, it’s crucial to follow safety protocols due to the potential hazards of some dye chemicals. Proper handling, including the use of gloves and eye protection, is essential.

Environmentally Responsible Disposal: Disposing of used dye solutions requires attention to environmental and safety regulations. Many dye solutions must be treated as hazardous waste. Consulting with environmental safety guidelines and disposing of waste according to local regulations is important to prevent environmental contamination and adhere to safety standards.

9. Buying Guide for Dye Lasers

In this section we provide a thorough and practical guide for potential buyers of dye lasers, covering all aspects from initial needs assessment to installation and training, ensuring a well-informed purchasing decision.

1: Determining Your Needs

- Assessing Application Requirements: The first step in purchasing a dye laser is to thoroughly assess your specific application needs. This includes understanding the wavelength range, power output, and pulse characteristics required for your work. Consider factors like the nature of your experiments, the materials involved, and the precision needed.

- Long-term Goals: Look beyond immediate requirements and consider your long-term goals. Anticipate the potential for future projects or expansions that may require additional features or capabilities from the dye laser.

2: Application-Specific Requirements

- Scientific and Research Needs: For scientific research, prioritize lasers with high precision, tunability, and stability. Consider lasers that offer a wide wavelength range if your research spans multiple disciplines.

- Industrial Applications: In industrial settings, durability and reliability take precedence. Look for lasers that offer robust construction and can withstand prolonged operational periods.

- Medical Applications: For medical applications, ensure that the laser meets all safety and regulatory standards. Lasers used in medical settings should offer precise control over output to ensure patient safety and treatment efficacy.

3: Budget Considerations

- Initial vs. Long-term Costs: Consider not only the initial purchase price but also long-term costs such as maintenance, consumables like dyes, and potential upgrades. A more expensive system might offer lower overall operating costs due to higher efficiency and durability.

- Funding and Grants: Explore funding opportunities or grants, especially in academic or research settings, which can influence the budget available for your purchase.

4: Key Features to Look For

- Wavelength Range and Tunability: Ensure the laser covers the necessary wavelength range for your applications. The ease of tunability is also a crucial factor for versatile applications.

- Power Output and Beam Quality: Evaluate the power output and beam quality requirements. Higher power might be necessary for industrial applications, while beam quality is more critical for precision tasks.

- Cooling and Stability: Consider the cooling mechanisms (air or water cooling) and overall system stability, especially for continuous operation.

5: Vendor Evaluation and Selection

- Reputation and Reviews: Research vendors’ reputations and customer reviews. Experience and reliability in manufacturing dye lasers are key indicators of quality.

- Support and Service: Look for vendors who provide strong customer support, including installation, maintenance, and troubleshooting services.

- Warranty and Parts Availability: Check the warranty period and availability of replacement parts. A longer warranty and readily available parts can be indicative of a reliable product.

6: Installation and Training

- Professional Installation: Ensure professional installation is part of the purchase. Proper installation is crucial for optimal performance and safety.

- Training Programs: Seek vendors that offer comprehensive training programs for your team. Adequate training ensures safe and efficient operation of the laser system.

10. Future Trends and Developments

The field of dye lasers is continually evolving, driven by technological innovations and emerging applications. Advanced research is leading to enhancements in dye laser technology, focusing on increasing efficiency, reducing size, and extending the lifespan of dye materials. Innovations like new dye formulations with higher stability and efficiency, and advancements in pump sources, are pushing the boundaries of what dye lasers can achieve. These developments promise more compact, powerful, and versatile dye laser systems, suitable for a broader range of applications.

Emerging applications of dye lasers are expanding into diverse fields. In the medical sector, there’s ongoing research into using dye lasers for more precise and less invasive treatments. The telecommunications industry is exploring the use of dye lasers in advanced optical communication systems, where their tunability could be pivotal in developing more flexible and efficient networks. Additionally, their application in environmental monitoring and detection of atmospheric pollutants is gaining traction, showcasing their potential in addressing global environmental challenges.

Environmental and safety considerations are becoming increasingly significant in the development and application of dye lasers. Manufacturers and researchers are focusing on developing eco-friendlier dye solutions and more efficient cooling systems to minimize environmental impact. Safety protocols are also being enhanced, with a focus on reducing risks associated with the handling of hazardous dye materials and exposure to high-intensity laser beams. Future developments will likely include stricter safety standards and more sustainable practices in the manufacturing and operation of dye lasers.

11. Conclusion

This guide has traversed the comprehensive landscape of dye laser technology, from the fundamental principles and components that define these versatile systems to the intricate considerations involved in their design, fabrication, and application. We’ve explored the significance of dye lasers in various fields, including scientific research, medical applications, and industrial processes, highlighting their unique capabilities in wavelength tunability and precision.

Through discussions on performance optimization, maintenance, and troubleshooting, we’ve underscored the importance of understanding and managing these complex systems to ensure their longevity and efficiency. The buying guide section aimed to equip potential buyers with the knowledge to make informed decisions, considering factors like application-specific requirements, budget constraints, and key features of dye lasers.

The Future Outlook of Dye Lasers

As we look towards the future, it’s evident that dye lasers, while still valuable in many specialized applications, are facing competition from newer laser technologies that offer advantages in terms of size, efficiency, and ease of use. Solid-state lasers and fiber lasers, for instance, are increasingly preferred in many areas where dye lasers were traditionally used.

However, the unique properties of dye lasers, particularly their tunability and the ability to generate ultra-short pulses, continue to make them relevant in specific scientific and medical applications. Innovations in dye laser technology, including improvements in dye formulations and system components, are likely to extend their viability in the face of evolving technological landscapes.

While acknowledging the shift towards more modern laser systems, it’s important to recognize that dye lasers still hold a significant place, especially in niche areas where their specific attributes are unmatched. Looking ahead, the dye laser technology may see more focused use, with continued research and development ensuring their relevance in applications where their unique capabilities are indispensable.

12. References and Further Reading on Dye Lasers

Academic Papers

- “Organic Dye Lasers: Brief History and Recent Developments” by Frank J. Duarte – This paper delves into the intriguing and versatile world of the organic dye laser, renowned for being the first broadly tunable laser. It comprehensively explores the dye laser’s remarkable ability to produce a diverse range of outputs – from ultrashort to high-energy pulses, and from stable continuous wave emissions to high average power outputs. It covers a spectrum of current applications in fields as varied as medicine, laser isotope separation, and fundamental physics research, showcasing the dye laser’s critical role in advancing technology and scientific understanding.

- “High Power Ultrafast Lasers” by Charles G Durfee – This article reviews the significant advancements in the development of high peak-power ultrafast lasers, focusing on the design considerations that are pivotal to the performance of these cutting-edge systems. It highlights the remarkable capability to construct terawatt peak power lasers with ultra-short pulse durations, achievable even in small-scale laboratory settings, and discusses the development of large-scale lasers capable of generating over a petawatt of peak power. The progress outlined in the article has been made possible through the adoption of chirped-pulse amplification, the use of broad-bandwidth laser materials like Ti:sapphire, and advancements in generating and propagating very short light pulses (10–30 fs). Additionally, the article touches upon the scientific breakthroughs enabled by this technology, such as the creation of coherent femtosecond x-ray pulses and the generation of high-energy electron beams and ions. This peer-reviewed piece from the American Institute of Physics offers a comprehensive overview of a rapidly evolving field in laser technology.

Books and Journals

- “Dye Lasers (Topics in Applied Physics, 1) ” by Fritz P. Schäfer, K.H. Drexhage, et al – A detailed textbook offering a thorough overview of the fundamental concepts, design, and applications of dye lasers.

- “Construction of a Flashlamp-Pumped Dye Laser and an Acousto-Optic Modulator for Mode-Locking” by D. A. Jennings – Excerpt from Construction of a Flashlamp-Pumped Dye Laser and an Acousto-Optic Modulator for Mode-Locking

- “Dye Laser Principles: With Applications (Quantum Electronics–Principles and Applications)” by Frank J. Duarte, and Lloyd W. Hillman – “Dye Laser Principles” provides a foundational tutorial to the field of dye lasers and offers a current perspective for those employing these lasers in research and industry. The book addresses various topics relevant to both dye lasers and laser technology as a whole. Each chapter is enriched with problem sets that further elaborate on the concepts discussed, enhancing the reader’s understanding of the material.

Where to buy Dye Lasers

For those interested in purchasing dye lasers, a valuable resource can be found at FindLight. This comprehensive online marketplace offers a wide selection of dye lasers suitable for various applications in research and industry. You can explore different models and specifications to find a laser that best fits your needs. Visit FindLight’s Dye Lasers page for more information and to browse available options.

Useful Videos on Dye Lasers

Check out this insightful video which delves into the guts of dye lasers. In this video the author build a high-power source of laser light in an array of colors and the fascinating ease of changing these colors just by switching the liquid dye.

And here is a video, showing a teardown and demonstration of a dye laser

13. Glossary of Terms for Dye Lasers

- Stimulated Emission: The process by which an excited atom or molecule, after being struck by a photon, releases two photons of the same energy, phase, and direction. This is the fundamental process behind laser operation.

- Optical Resonator: A set of mirrors in the laser that confines and reflects the emitted light back into the lasing medium to induce further emission. It determines the characteristics of the laser output.

- Photon Coherence: A property of light emitted by lasers in which the light waves are in phase in both time (temporal coherence) and space (spatial coherence), leading to a highly collimated and focused beam.

- Dye Concentration: The amount of laser dye present in the solvent within the dye laser. It’s crucial for determining the efficiency and output wavelength of the laser.

- Wavelength Tunability: The ability of the dye laser to adjust its output to different wavelengths. This is achieved through changing the dye or adjusting optical components like diffraction gratings.

- Lasing Medium: The material in a laser that generates the laser beam. In dye lasers, this is typically a liquid solution of organic dye.

- Quantum Efficiency: The efficiency with which absorbed energy is converted into emitted light. High quantum efficiency in dye lasers means more efficient lasing action.

- Pump Source: The external energy source used to ‘pump’ the dye molecules into an excited state, initiating the lasing process. Common pump sources include flashlamps and other lasers.

- Beam Quality: A measure of the laser beam’s focusability and consistency, often characterized by factors like beam divergence and brightness.

- Photostability: The resistance of a dye to degradation when exposed to light. High photostability in laser dyes is desirable for prolonged laser operation without the need for frequent dye replacement.

- Mode-Locking: A technique used in lasers to produce ultra-short pulses of light by causing all modes of the laser’s resonator to oscillate in phase.

- Diffraction Grating: An optical component used in dye lasers to select a specific wavelength for output, based on the diffraction and interference of light.

- Flashlamp: A type of pump source that provides intense, broad-spectrum light, used to excite the dye in a dye laser.

- Continuous Wave (CW) Operation: A mode of laser operation where the laser produces a continuous, steady beam of light, as opposed to pulsed operation.

- Pulsed Operation: A mode of laser operation where the laser emits light in short, high-intensity bursts.