Elemental analysis provides a deeper look into the materials we see and use every day. Courtesy of CKiC.

Introduction to Elemental Analysis

All matter on Earth is composed of an assortment of 118 elements. The possible combinations are endless, with varying quantities of molecules and components in a material. While some substances are simple, such as water (H2O) containing only two elements, complex mixtures, like concrete or pharmaceuticals, contain many more. Knowing the composition of a material ensures that a product is safe to consume, an aircraft is safe to fly, or that the gold ring you hope to buy is truly worth the price. Elemental analyzers provide us with a deeper understanding of everyday materials.

How It Works

There are many different techniques available to analyze material composition. These include combustion analysis, gravimetry, optical atomic spectroscopy, mass spectrometric atomic spectroscopy, along with several chemical-based methods. However, this article will focus on the operating principles and applications of infrared (IR) combustion analyzers and X-ray based analyzers.

IR Combustion Analysis

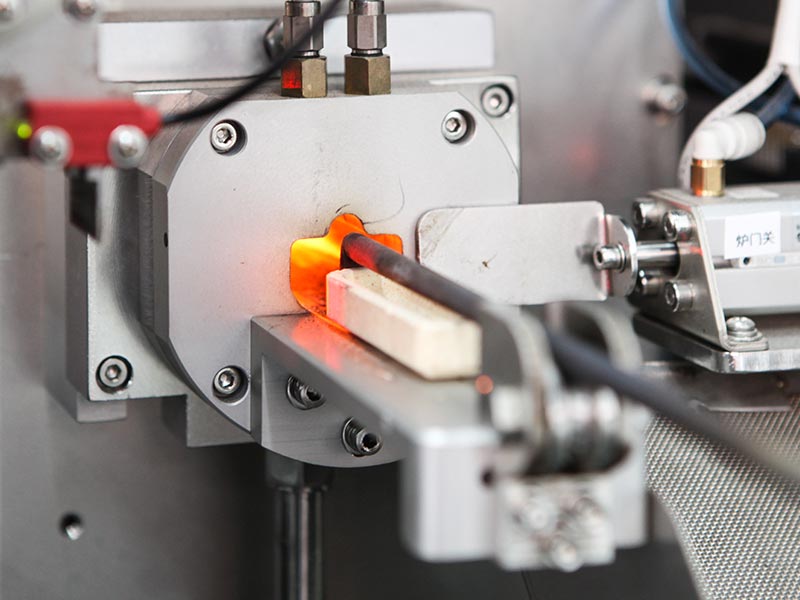

IR combustion elemental analyzers utilize IR and thermal conductivity detectors to determine and quantify the various components in a material. The IR detectors rely on the way in which IR radiation reacts when it comes into contact with different types of matter. For example, when IR light hits an oxygen molecule, a certain amount of light is absorbed. When the chamber containing the sample absorbs IR light, the detector heats up and expands. This expansion causes a change in pressure, which can then be compared to a reference chamber of known composition and concentration. The quantity of light absorbed differs from molecule to molecule, corresponding to specific pressure changes in the sample chamber. This allows scientists to accurately determine which elements compose a material and how much of each element is present.

Infrared combustion analysis uses infrared and thermal conductivity detectors to determine material composition. Courtesy of CKiC.

IR detectors are typically paired with thermal conductivity detectors, which are useful in detecting elements such as nitrogen or hydrogen. Thermal conductivity detectors are similar to IR detectors in operating principle, however, thermal conductivity detectors analyze sample composition using changes in thermal conductivity rather than IR absorption.

This type of technology offers a high degree of sensitivity and precision. Many instruments that employ IR analysis are able to detect micro-quantity samples to high concentration samples. General applications include research and development purposes along with quality control in a variety of fields and processes.

X-Ray Based Elemental Analyzers

Another elemental analysis technique relies on the use of X-rays. X-rays are commonly used in analytical devices due to their non-destructive nature, which allows a sample to stay intact after analysis. Several different technologies utilize X-rays, including X-ray diffraction and scattering and total reflection X-ray fluorescence spectroscopy (TXRF).

One of the most versatile X-ray based elemental analyzers are X-ray fluorescence (XRF) analyzers. XRF technology comes in many shapes and sizes, including handheld devices, micro-XRF systems, and TXRF devices. XRF elemental analyzers operate based on how atoms behave as they are exposed to primary X-ray waves.

The first step in XRF analysis involves exposing a material to the primary X-ray wave source. High-energy waves bombard the atoms in the sample, causing electrons of the atoms to shift and drop energy levels. This results in fluorescence, or secondary X-ray emission. Measurement of fluorescence provides information on sample composition. Similar to IR combustion technology, each element has a characteristic “fingerprint” that distinguishes it from other elements. Various types of detectors, such as semiconductor-type or analyzing crystals, are used to detect the intensity of the emitted wavelengths, allowing scientists to distinguish elements in a sample.

Handheld XRF devices are useful for determining the purity of metals. Courtesy of Olympus IMS.

XRF technology is especially useful in the detection of metals, glass and ceramics, however, these analyzers have the ability to quantify almost every element on Earth. It is completely non-destructive and does not affect the sample in any way. The high-energy X-rays also allow for deeper sample penetration depth compared to other technologies. Additionally, it is widely versatile as it can process sample types ranging from powders to liquids. XRF can test samples quickly and requires minimal operator input, providing the user with a simple and convenient method to determine real-time composition.

Applications of Elemental Analyzers

Elemental analysis finds applications in a variety of fields including environmental, jewelry, food and medicine, forensics, aerospace, and more. Determining the composition and characteristics of a material is an invaluable tool that continues to benefit society on micro and macro scales.

Environment

With the number of cars worldwide predicted to have passed 1 billion, the petroleum industry has faced recent changes in the need to monitor the quality of the fuels they produce. Several advances in elemental analysis, such as the XRF Sulfur-in-oil analyzer, include specific designs to measure new low sulfur fuels, diesel and reformulated gasoline to make sure they meet current standards. The ability to measure and monitor the elements of a fuel is the first step toward improving overall quality.

Precious Metal Analysis

The ability to distinguish between a pure substance and an impure substance is crucial in a variety of fields. However, elemental analysis is especially useful in determining the value of gold jewelry, coins, bars and other objects that cannot be analyzed using just the human eye. The same holds true for other precious metals like silver and platinum. Today, society holds high values for such metals, and the ability to determine the true worth of metals benefits jewelry stores, thrift and pawnshops, and individual sellers everywhere.

Food Industry

Another application of elemental analysis is in the food industry, where the low detection limits of TXRF devices are optimally suited for trace element analysis. This includes determining the nutritional value and quality of foods and beverages along with ensuring products are safe for consumption. Without the ability to determine the nutrients in a product or assure that a food is safe to eat, many products would not be available for consumption as they are today.

Forensic Science

In addition, modernized technology is now capable of visualizing evidence long after it is invisible to the human eye. Common forensic uses for handheld XRF devices are gunshot residue, glass fragment, and paint chip analysis. Because X-ray technology is non-destructive, forensic evidence can be analyzed without disturbing or contaminating the sample.

XRF technology finds applications in art authentication. Courtesy of The Fitzwilliam Museum, Cambridge.

Additionally, XRF devices are able to handle materials like pigments, ceramics, glazes, alloys, glass, and varnishes. This holds great importance in art and historical industries when analyzing art pieces and historical documents for authenticity. Cross-referencing materials used in an artwork with materials available during the artist’s lifetime provides valuable information on whether it is authentic. Furthermore, XRF devices easily distinguish between original and non-original materials, indicating whether or not a document has been tampered with.

Aerospace

As the aerospace industry continues to expand, so does the demand for improved aircraft and spacecrafts. Today, many major alloys used in aerospace applications are titanium, stainless steel, nickel super-alloys, and cobalt super-alloys. In the past, issues found in a particular aircraft required destructive and costly methods to repair the problem. Recent advances in elemental analysis technology have allowed for non-destructive testing, forever changing how the aerospace industry maintains their vessels. Additionally, elemental analysis devices can easily detect metal fatigues and impurities. This unique characteristic provides quality assurance and has the potential to prevent accidents before an aircraft even takes flight.

Conclusion

In conclusion, elemental analyzers are extremely powerful characterization tools with endless applications. The capability to distinguish between various elements in a sample helps predict how matter will behave in certain situations or how the presence or absence of a material effects a process. This equates to more durable equipment, safer foods and medicines, and generally, a more thorough understanding of material nature and the many qualities they attain.