In this article we delve into the transformative role of Process Analytical Technology (PAT) and fiber optics in modern manufacturing, spotlighting their impact on efficiency, quality, and real-time process control across various industries. Through an exploration of cutting-edge spectroscopic techniques and in-depth case studies, we uncover the potential of these technologies to redefine manufacturing paradigms.

Table of Contents

- Introduction

- Understanding PAT and Its Importance

- The Advent of Fiber Optic Probes in PAT

- Integration of Spectroscopic Techniques with PAT via Fiber Optics

- Case Studies and Applications

- The Future of PAT and Fiber Optics

- Conclusion

- References

FlexiSpec® Cleanable Fiber Probe integrated with PAT for precise, contamination-free process analysis. Courtesy of art photonics, GmbH.

Today’s article is sponsored by art photonics, GmbH, global leader in development and manufacturing of specialty fiber products for a broad spectral range from 300nm to 16µm.

1. Introduction to Process Analytical Technology

In modern manufacturing, Process Analytical Technology (PAT) stands as a fundamental framework, significantly enhancing process monitoring and control across various industries. At its core, PAT leverages timely measurements of critical quality and performance attributes to enhance understanding and management of manufacturing processes. This technology is not just about monitoring; it’s a comprehensive approach to improving manufacturing outcomes through real-time data and analysis.

The advent of remote sensing technologies has further accelerated the capabilities of PAT. Remote sensing, particularly through advancements in fiber optic probes, allows for the precise, real-time monitoring of processes without the need for direct contact with the materials being processed. This leap in technology enables industries to surpass traditional barriers of process analytics, facilitating a shift towards more efficient, accurate, and flexible manufacturing paradigms.

Traditionally, Process Analytical Technology (PAT) focused on basic monitoring and control, emphasizing end-product testing and periodic manual sampling. The integration of fiber optic probes and advanced sensors now allows PAT to provide continuous, in-line measurements, significantly broadening its scope and offering a deeper, real-time insight into manufacturing processes. This integration not only enhances the accuracy and timeliness of data collected but also opens new avenues for the application of spectroscopic techniques directly within production lines. The result is a significant uplift in the efficiency and reliability of process control mechanisms, enhancing quality and performance in manufacturing.

2. Understanding PAT and Its Importance

Process Analytical Technology (PAT) is a regulatory framework introduced by the FDA, aimed at enhancing the understanding and control of manufacturing processes in the pharmaceutical industry. PAT focuses on real-time monitoring of Critical Process Parameters (CPPs) to ensure the final product’s quality, defined by its Critical Quality Attributes (CQAs). This approach shifts the industry from a traditional quality-by-testing model to a more proactive quality-by-design paradigm.

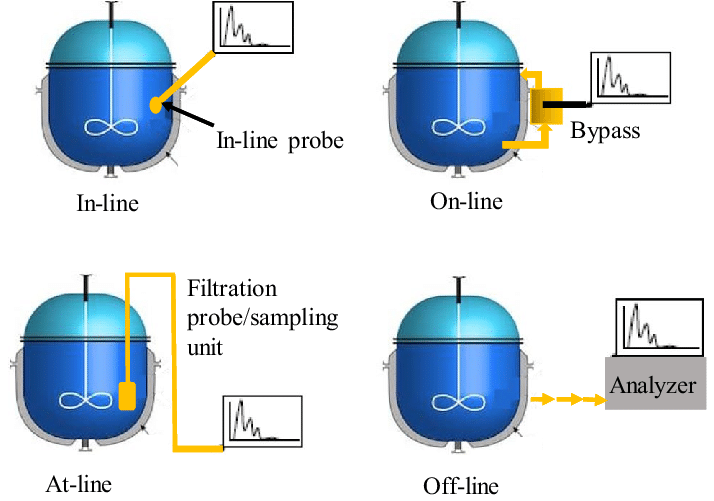

Traditionally, process monitoring has been categorized into offline, at-line, on-line, and in-line techniques. Offline analysis involves testing samples removed from the process and analyzed in a separate laboratory, often resulting in delayed feedback. At-line refers to the analysis conducted near the production line but still requires removing samples from the process flow. On-line analysis allows for the monitoring of processes in real-time without sample removal, but the sensors are not integrated within the process equipment. In-line monitoring, the most advanced form, involves fully integrating sensors and analytical instruments into the process stream, providing real-time data without interrupting the process.

A schematic representation of different PAT methods including in-line (top-left), on-line (top-right), at-line (bottom-left), and off-line (bottom-right) techniques for comprehensive process analysis. Image courtesy of ResearchGate.

These traditional methods, especially offline and at-line, face limitations in providing real-time control and immediate feedback, critical for optimizing process efficiency and product quality. PAT, with its emphasis on real-time and in-situ measurements, seeks to overcome these challenges, enabling more agile and responsive manufacturing processes. By leveraging technologies such as spectroscopy and chemometrics within a PAT framework, manufacturers can achieve a more profound, data-driven understanding of their processes, leading to enhanced product quality and process efficiency.

If you are enjoying this article, you might also be interested in our white paper on ATR Probes for Harsh Environments.

3. The Advent of Fiber Optic Probes in PAT

The integration of fiber optic probes in Process Analytical Technology (PAT) marks a significant advancement, transforming the landscape of real-time process monitoring. Fiber optics, a technology fundamentally based on the transmission of light through thin, flexible fibers, enables the remote sensing of process materials. These probes utilize spectroscopic principles, including UV-VIS, NIR, Raman, or mid-IR spectroscopy, to transmit spectroscopic signals to and from the process stream. For instance, mid-IR often employs ATR spectroscopy, while UV-VIS/NIR might use transmission for liquids or reflection for powders or solid samples.

This non-invasive approach to spectroscopic sensing facilitates in-line measurements, allowing for the continuous monitoring of critical process parameters. The ability of fiber optic probes to deliver and collect light from the material under examination makes it possible to conduct real-time spectroscopic analyses. This capability is pivotal in industries where maintaining the integrity of the process environment is crucial, such as pharmaceuticals, food, and chemicals.

Fiber optic probes, when integrated with PAT, provide a seamless link between the process material and analytical instruments. This connection not only ensures the acquisition of real-time data but also enhances the safety and efficiency of the manufacturing process by minimizing the need for manual sample collection and analysis. The advent of these probes has ushered in a new era of process monitoring, where decision-making is driven by immediate, actionable data, leading to optimized process control and product quality.

4. Integration of Spectroscopic Techniques with PAT via Fiber Optics

The integration of spectroscopic techniques with Process Analytical Technology (PAT) via fiber optics marks a transformative convergence of analytical precision and operational efficiency in manufacturing. This is exemplified in the realm of pharmaceutical production, where in-line Raman spectroscopy facilitates the monitoring and feedback control of continuous processes. For instance, the use of in-line Raman spectroscopy in a continuous twin-screw pharmaceutical powder blending and tableting process offers real-time analysis of active pharmaceutical ingredients (APIs), excipients, and lubricants. This application has demonstrated the capability to produce highly homogeneous blends and detect technological malfunctions, leading to a paradigm referred to as ‘Process Analytically Controlled Technology’ (PACT), ensuring consistent API content and enhancing the overall quality assurance process.

Similarly, Near-Infrared Spectroscopy (NIRS), though lagging behind in the number of applications compared to Raman spectroscopy, provides rapid and non-destructive analysis, when coupled with chemometrics. It becomes a versatile tool for both qualitative and quantitative analysis in solid, liquid, and biotechnological pharmaceutical forms. NIRS is instrumental in the classification and regression analysis of pharmaceutical products, ensuring blend homogeneity and content uniformity crucial to the quality of the final product. The continuous real-time monitoring capabilities of NIRS support the transition from batch to continuous manufacturing, highlighting the potential of spectroscopic techniques to optimize manufacturing processes, reduce operating costs, and ensure easier scale-up and shorter time-to-market.

These instances underscore the broader adoption of PAT augmented with fiber optics in various industries. The impact of such integration extends beyond pharmaceuticals, predicting similar efficiency gains in the petrochemical and food industries, where process control, product quality, and waste reduction are equally paramount. As the body of research and application grows, the future of PAT and fiber optics stands at the cusp of broader industrial transformation, promising an era where quality and efficiency are inseparable facets of manufacturing.

5. Case Studies and Applications

Pharmaceutical Industry: The implementation of PAT, supplemented by fiber optic probes, has revolutionized the pharmaceutical industry’s approach to drug formulation. In-line Raman spectroscopy, integrated within a continuous twin-screw powder blending and tableting line, exemplifies this advancement. This technology has enabled real-time analysis of APIs, excipients, and lubricants, producing highly homogeneous blends. Such precision in monitoring has led to the inception of ‘Process Analytically Controlled Technology’ (PACT), guaranteeing the uniformity of API content and significantly enhancing the reliability of the quality assurance processes. Consequently, pharmaceutical companies have observed a marked reduction in batch rejection rates and an upsurge in product consistency.

Petrochemical Industry: In the petrochemical sector, the application of PAT using fiber optic probes for the real-time spectroscopic analysis of crude oil streamlines the refining process. This facilitates immediate adjustments to processing parameters, contributing to a reduction in energy consumption and minimizing waste. Such efficiency gains not only bolster operational performance but also support environmental sustainability initiatives within the industry.

Food Industry: The food industry benefits similarly from the integration of PAT technologies. For instance, the monitoring of moisture content and composition in dairy products through Near-Infrared Spectroscopy (NIRS) has been instrumental in ensuring product quality. The ability to perform real-time, non-destructive analysis through fiber optics ensures that products maintain their quality from production to point-of-sale, leading to extended shelf life and reduced waste, thus reflecting an overarching impact on the supply chain.

These case studies underscore the pivotal role of PAT augmented by fiber optics in enhancing operational efficiency, product quality, and sustainability. As such, the adoption of these technologies is anticipated to expand further, forecasting a transformative impact on manufacturing practices. The ongoing research and growing application base suggest a future where integrated PAT systems are a standard, driving industries toward more intelligent, efficient, and quality-focused manufacturing solutions.

6. The Future of PAT and Fiber Optics

The frontier of Process Analytical Technology (PAT) integrated with fiber optics is expanding rapidly, propelled by continuous advancements in spectroscopic techniques and probe design. These technologies come together to start a new era in manufacturing, where precision engineering is led by data and real-time analysis. Future developments are poised to include advances in miniaturization, increased spectral range, and sensitivity of fiber optic probes. These innovations are likely to open up new applications in challenging environments, such as extreme temperatures and pressures or hazardous conditions, where traditional analytical methods are impractical.

The prospect of integrating cutting-edge materials within fiber optic sensors could offer breakthroughs in sensitivity and selectivity, further enhancing the capabilities of PAT systems. Additionally, advancements in computational power and machine learning are expected to refine the data interpretation from spectroscopic analysis, providing deeper insights and more predictive power in process control.

Moreover, the application scope of PAT is set to expand further, extending into industries such as aerospace and environmental monitoring, where material integrity and process efficiency are crucial. The environmental sector, for instance, could benefit from the real-time monitoring capabilities of PAT in pollution control and waste management processes, aligning with global sustainability goals.

Another promising direction is the integration of PAT systems with the Industrial Internet of Things (IIoT), facilitating a more interconnected and smart manufacturing environment. This connectivity could enable a seamless flow of information between different stages of production and supply chain management, optimizing the entire lifecycle of products.

The ongoing push towards green manufacturing practices is also likely to influence the future of PAT and fiber optics. The drive for processes that minimize waste and energy use aligns with the in-situ, non-destructive analytical nature of PAT, making it a key player in sustainable industry practices.

7. Conclusion

The pivotal role of fiber optics in enhancing Process Analytical Technology (PAT) through remote spectroscopic sensing has ushered in a new era of manufacturing intelligence. By enabling in-line, real-time analysis without direct contact, fiber optics have significantly expanded the capabilities of PAT across diverse sectors, from pharmaceuticals to petrochemicals and food processing. This technological synergy has led to profound advancements in process understanding, allowing for unprecedented control over manufacturing processes. The benefits of this integration are manifold, including improved product quality, increased manufacturing efficiency, and reduced waste, thereby contributing to sustainable manufacturing practices.

Moreover, the adoption of fiber optic-enabled PAT has facilitated a shift towards more agile and responsive production lines, capable of adapting to changing conditions and demands with minimal downtime. This adaptability is crucial in today’s fast-paced market environments, where the ability to quickly adjust and optimize production processes can be a significant competitive advantage.

Looking ahead, the ongoing evolution of fiber optic technologies and their integration with PAT promises even greater advancements. As these technologies become more sophisticated and accessible, their adoption is expected to widen further, impacting a broader range of industries and applications. This widespread adoption will not only drive efficiency and quality improvements but also foster innovation in manufacturing processes and products.

8. References

For foundational knowledge on PAT:

- Process analytical technologies in the pharmaceutical industry: the FDA’s PAT initiative; Dirk C Hinz | Anal Bioanal Chem, Vol 384, p1036-1042, 2006.

- Guidance for Industry PAT — A Framework for Innovative Pharmaceutical Development, Manufacturing, and Quality Assurance, FDA, 2004.

- Process analytical technology in the pharmaceutical industry: A toolkit for continuous improvement; Scott, B.; Wilcock, A. | PDA Journal of Pharmaceutical Science and Technology / PDA. 60 (1): 17–53. 2006.

- Process Analytical Technologies (PAT) – Overview, Wikipedia

On the principles and applications of fiber optics in PAT:

- Applications of process analytical technology to crystallization processes; Lawrence X Yu, Robert A Lionberger, Andre S Raw, Rosario D’Costa, Huiquan Wu, Ajaz S Hussain | Advanced Drug Delivery Reviews, Volume 56, Issue 3, 23 February 2004, Pages 349-369

- Process analytical technology (PAT) for biopharmaceutical products: Part II. Concepts and applications; E.K. Read, R.B. Shah, B.S. Riley, J.T. Park, K.A. Brorson, A.S. Rathore | J. Biotechnology & Bioengineering

Regarding spectroscopic techniques integration with PAT:

- A review of near infrared spectroscopy and chemometrics in pharmaceutical technologies; Roggo, Y.; Chalus, P.; Maurer, L.; Lemamartinez, C.; Edmond, A.; Jent, N. | Journal of Pharmaceutical and Biomedical Analysis. 44 (3): 683–700, 2007.

- In-line Raman spectroscopic monitoring and feedback control of a continuous twin-screw pharmaceutical powder blending and tableting process; Nagy, B; et al. | International Journal of Pharmaceutics. 530 (1–2): 21–29, 2017.

Case studies on the application in industries:

- Development of a Process Analytical Technology (PAT) for in-line monitoring of film thickness and mass of coating materials during a pan coating operation; Gendre, C.; Genty, M.; Boiret, M.; Julien, M.; Meunier, L. C.; Lecoq, O.; Baron, M.; Chaminade, P.; Péan, J. M. | European Journal of Pharmaceutical Sciences. 43 (4): 244–250, 2011.