From the device that you are looking at to the international space station, glass is the invisible material that improves our daily life. A large class of glass materials are derived from quartz, or most notably, silicon dioxide. Quartz is found everywhere on earth in the form of tiny grains of sand located everywhere at your nearby beach or even just outside on the street. Once melted and solidified using different techniques, it becomes the glass we see everywhere. In this blog post we will cover the processes of different types of glass creation and applications.

- History of Glass

- Why is Glass Transparent

- Annealed Glass Creation

- Heat-Strengthened Glass Creation

- Tempered Glass Creation

- Laminated Glass

- Conclusion

1. History of Glass

The first ever glass creation dates back to 2500 BC when Egypt displayed signs of having created this material. But the method and requirements for creating glass are still the same today, namely using intense amounts of heat. That said, the process is a little different in the modern world: combining recycled glass, sand, calcium carbonate, and sodium carbonate in a furnace and bringing it up to a temperature of at least 1700C (3090F) the grains melt. The liquid is then poured into a mold where it can form into the desired shape.

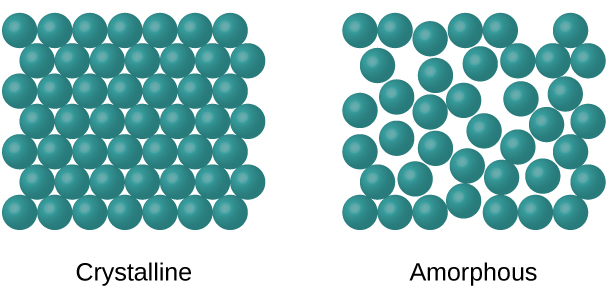

Interestingly, glass can be considered both solid and liquid due to its unique properties. Essentially, glass is an amorphous solid: a solid that exhibits characteristics of a liquid on the atomic scale. The atomic structure of glass is irregular and unlike a true solid such as metal. While metals have a uniform and repetitive crystalline structure, glass is disordered.

Crystalline vs Amorphous Solid Structure. Image courtesy of LibreTexts.

2. Why is Glass Transparent?

Typical glass is transparent in the visible (VIS) range of the spectrum. This is because of the specific energy level structure of quartz atoms inside the glass, which are at levels that do not match the photon energy in the VIS region of the spectrum. Electrons require precise wavelengths of energy to be excited onto another level. Thus light passes through the material without being absorbed in the atoms of quartz. For a typical glass this gradually changes as we approach the UV side of the spectrum with wavelengths below 300nm, which become high enough to be absorbed and excite quartz atoms.

Similarly certain colors of glass can be explained by the absorbed and emitted wavelengths of light. In a colored glass the energy structure is altered by introducing impurities such that certain wavelengths (photon energy levels) become adequate for energy transition. Thus some wavelengths become absorbed while others pass through giving rise to the colors of glass. This is how optical filters work.

3. Annealed Glass Creation

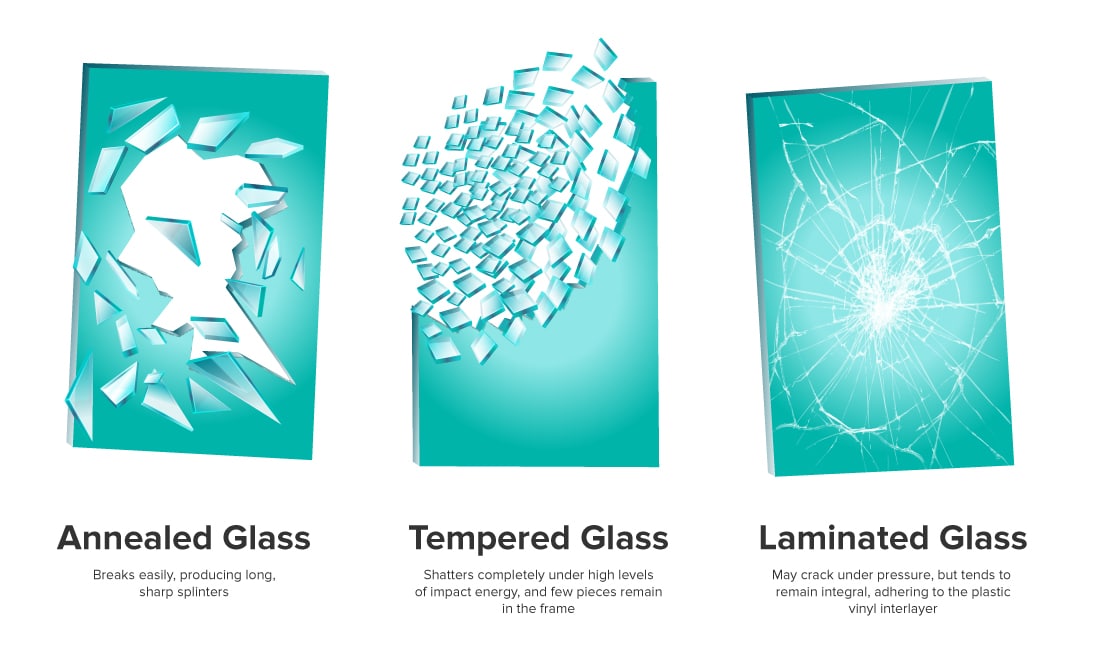

Annealed glass is the most delicate glass that you can find. Like any other glass, it is initially a liquid and then cooled. The liquid glass is removed from the furnace and is left at room temperature to cool. The longevity of time will relieve stress in the structure and create a delicate solid. In doing so it obtains the property of uniformity. Annealed glass can be cut, drilled, or processed relatively easily and without high risks of shattering. However, when annealed glass shatters, the shards are in large pieces.

The pushing and pulling stresses in the atomic structure of the glass strengthen the entire piece. However, when one of these points is misaligned, the entire system collapses. The result is a large pile of glass shards, not making this an adequate choice for buildings with high safety regulations. That said, annealed glass is often used in tabletops, cabinet doors, and basement windows.

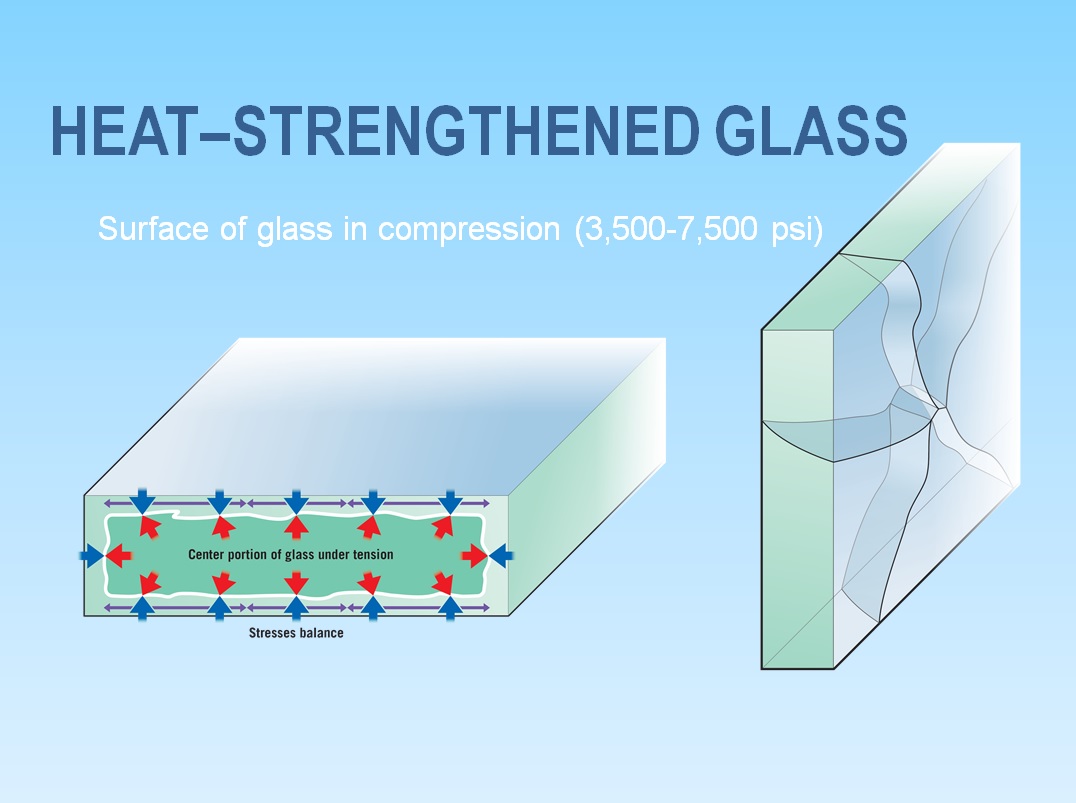

4. Heat-Strengthened Glass Creation

To make heat-strengthened glass, manufacturers can reheat annealed glass to a temperature of around 650C to 700C. At this temperature, the atomic structure of the glass transforms into a liquid and solid-like mixture, similar to an amorphous state. The glass is then cooled at an accelerated rate, making the outer edge of the glass solidify and creating pressure on the inside of the glass. This pressure is what makes the glass even stronger than annealed glass. In fact, this pressure makes heat-strengthened glass two times stronger than annealed glass. Although it can withstand wind and heat changes, it is still not strong enough to drill or sandblast. Once fractured, the shards are in similar size as in annealed glass. Due to the accelerated cooling, the resolution of the structure is slightly distorted but not as much as that of a tempered glass.

Heat strengthened glass and stress points. Image courtesy of Vitro.

5. Tempered Glass Creation

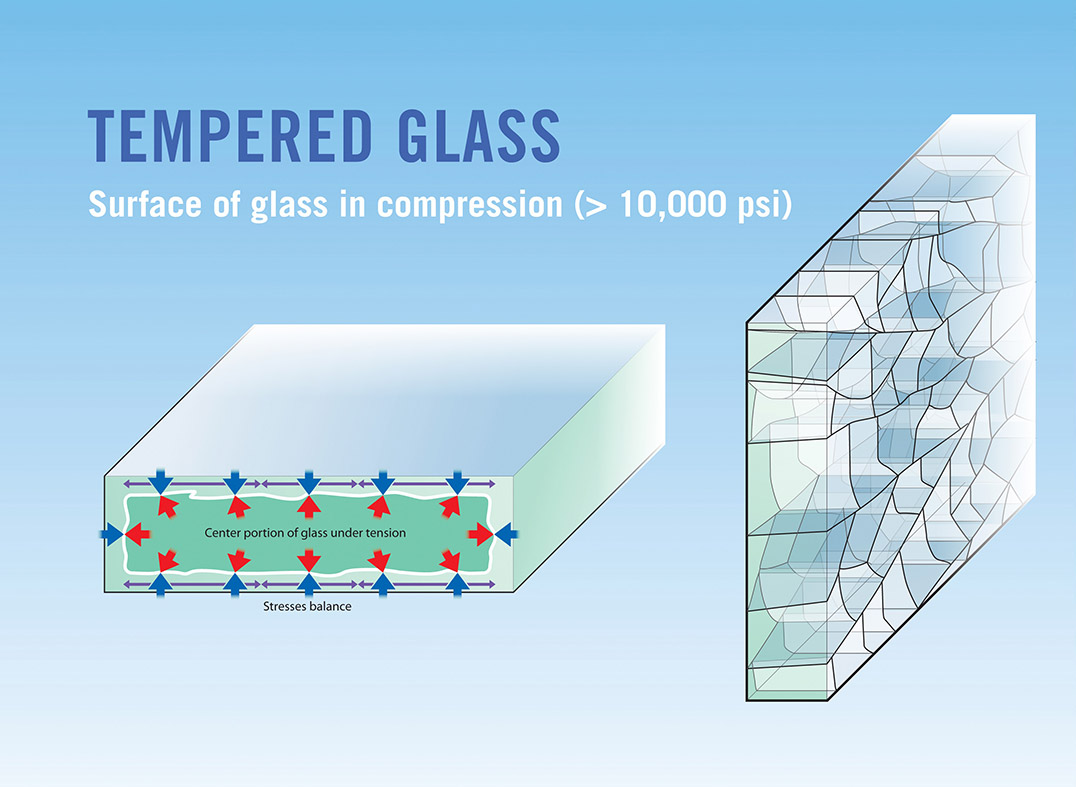

You have probably heard of this type of widely used glass. Due to its mechanical strength and small shard size, tempered glass is the optimal choice for any construction project. This glass is created by taking annealed glass and heating it through conduction up to a temperature of 700C and then “quenching”. Quenching is the process of blasting high-pressure air onto molten glass, leading to rapid cooling.

Consequently, rather than the atoms having time to cool and align themselves in the orientation that releases the most stress, pressure remains trapped inside the glass. As a result of this pressure, the strength of tempered glass is around five times stronger than annealed glass. Once the glass is compromised, the shards are in small pieces, making it safer for buildings. Tempered glass is widely used for home windows, showers, and car windshields.

Heat strengthened glass and stress points. Image courtesy of Vitro.

6. Laminated Glass

Glass can be laminated with a thin filament. Often a layer of laminate is sandwiched between two glass panes. This can create a high-security glass that will not leave pieces of glass once it is shattered. The most common filament is polyvinyl butyral (PVB), which is a thermoplastic that can be bound to glass panels with amazing optical clarity.

Laminating glass is also used to create bulletproof glass, however, a tougher polycarbonate intermediate is sometimes used. How does this help to stop a bullet you might ask? As a bullet hits the first layer of glass, the inward force is distributed to the polycarbonate layer. The plastic will do its best to keep the balanced forces within the glass constant by slowing down the spread of the crack through adhesion. The bullet will come to a rest, transferring all of its kinetic energy to the glass structure.

The 3 different types of glass are compared. Image courtesy of Glazcon.

Such a multilayer glass shield is capable of defending against the bullets from various caliber guns. For instance, a sandwiched glass with 1-inch thickness can sustain .357 Magnum rifles bullets.

7. Conclusion

Glass creation is essential in our daily lives and it is something that we cannot possibly live without. The discussed above methods of creating and altering the material from the very beginning to meet the specifications of projects can be applied to many materials such as steel or different metal alloys. However, glass, over time lent itself to perfecting these technologies becoming a unique material useful in various industries. Glass has found applications in many domains, from automotive to construction industries. It is noteworthy to also briefly touch on its utility in the photonics industry that makes use of the highly engineered forms of this materials. From lenses to bandpass filters, to complex optical objectives all utilize some form of glass. It is hard to imagine the current state of the high-tech without utilizing glass.

Today's blog post was sponsored by World Star Tech - maker of lenses, alignment lasers and laser markers.