Introduction

In this article we will discuss the use of HWG and PIR fibers for CO2 and CO laser beam delivery. Since their invention over half a century ago, CO2 and CO lasers have attracted the attention of many researchers and industries for their versatility, conversion efficiency, and pulse energy which made them far superior to other lasers. They are notably popular in medical applications like dermatology, skin resurfacing, dentistry, neurosurgery, and plastic surgery.

Before moving on to the details on this topic, FindLight would like thank art photonics GmbH for the support in writing this article. art photonics is a leader in the development and production of specialty fiber products for a wide range of applications. Their technologies of Polycrystalline Mid Infrared (PIR-) fibers and Metal coated Silica fibers are widely used in various spectroscopy probes for medical diagnostics and industrial process control.

Operating at very long wavelengths (5-6 µm for CO lasers and 10.6 µm for CO2 lasers), these lasers are excellent for soft-tissue surgery as they offer the ability to both cut and coagulate skin using the same instrument. For some of the medical applications mentioned, a flexible beam delivery system must be integrated with the laser source. This system will guide the light from the source to the application all the while protecting the laser from damage and facilitating the work of surgeons and medical professionals.

Flexible delivery systems are especially critical in laser surgery as they are easy to handle and maneuver. While other delivery systems, like the articulated arm, exist, a flexible delivery system is preferred. One of the most popularly used beam delivery systems is optical fibers, but can they be used to transmit CO2 and CO laser radiation? The answer is no. Standard optical fibers used in optical networks and telecommunications are made of fused silica, a material characterized by its high absorptivity (or absorption) in the mid-infrared range (mid-IR) with wavelengths > 2 µm. Therefore, using this type of fiber will result in high percentages of power loss.

Historically, this had been an issue for a long time. The absence of a technology that could support infrared radiation limited the integration of CO2 and CO lasers in medical applications. Fortunately, this issue has been solved when highly transmissive mid-IR fibers, such as HWG and PIR fibers, were invented. In this article, we will discuss some of the most popular flexible laser beam delivery systems based on HWG and PIR fibers that can be used with CO2 and CO laser and ways to improve their performance.

History of Mid-IR Fibers and Beam Delivery

Scientists started to investigate infrared (IR) materials around the 1960’s and were able to fabricate the first-ever IR fiber in the mid-1960’s. However, the development of IR fibers was slow until the mid-1970’s. During this period, there was a growing interest in researching these optical components motivated by the need for a fiber that could transmit long wavelength radiation in military sensing applications.

By 1975, there were several IR and mid-IR fibers, and the focus shifted to optimizing them. Infrared optical fibers can be divided into 3 categories: glass, crystalline, and hollow waveguides. In the rest of the article, we will explore in-depth 2 of these categories.

Silver Halide (PIR) Fibers

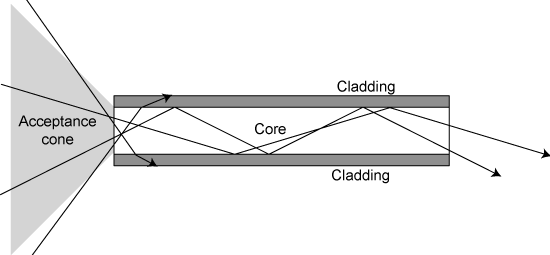

Silver Halide fibers are polycrystalline infrared (PIR) optical fibers characterized by high transmittance in the mid-infrared. Like standard optical fibers, PIR fibers propagate light by total internal reflection. They are comprised of a core and a cladding made from hallide materials such that the refractive index of the core is higher than that of the cladding. art photonics GmbH reports a transmission of around 70% for a 1-meter of such fiber for wavelengths ranging from 3 µm to 17 µm. These PIR fibers are also characterized by low attenuation levels.

One of the biggest advantages of Silver Halide fibers is their flexible delivery and mechanical strength. These properties allow the fiber to be bent without exhibiting significant power loss. However, despite their low absorption in the mid-IR range, these fibers suffer from Fresnel reflection losses at the ends of the fiber which significantly reduce the transmittance. Therefore, PIR fibers must be treated to minimize Fresnel losses and reach optimal power transmission. In the following few sections, we will discuss the different possible methods of treating PIR fibers that reduce transmission losses.

Longitudinal cross section of a cylindrical step-index optical fiber showing the core and cladding. Courtesy of Wikimedia Commons.

Methods for Treating Silver Halide (PIR) Fibers

As mentioned above, Fresnel reflection losses hinder the performance of PIR optical fibers and induce power loss. This effect arises from the high-refractive-index contrast between air (n_air = 1) and the fiber (n_halide = 2.1 in mid-IR). In a recent study, art photonics estimated that the power loss at each end of the fiber (fiber-air or air-fiber interface) to be around 13% making the overall power loss 25% for one fiber. Fortunately, there are several methods for treating Silver Halide fibers and improving power transmission to up to 90%. In the sections below, we will consider some of these techniques. Readers interested in learning more about fiber microstructuring methods may refer to the reference sources provided at the end of this article.

Anti-Reflective Caps

One way of reducing Fresnel reflection losses would be by using anti-reflective (AR) caps. These caps, which have been coated with an anti-reflective film, are attached to the ends of the PIR fibers. Reports show that the transmission of a PIR fiber increases to 92.5% when attached to an AR cap.

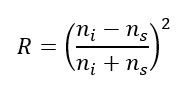

The anti-reflective film has a refractive index in between that of air and the halide material the fiber is made of. This choice can be explained by the reflectance equation shown below:

Where n_i and n_s are the refractive indices of the input and second medium, respectively. So, by reducing the difference in refractive index between 2 media, the reflectance decreases, and the overall reflectivity is reduced.

While anti-reflective caps are great for reducing the power density on the input surface of the fiber as well as Fresnel reflections, they are limited by their low damage threshold (the coating degrades for high power levels) and their not-so-broad spectral range (range of frequencies or wavelengths over which the coating has the best performance).

Anti-Reflective Microstructuring

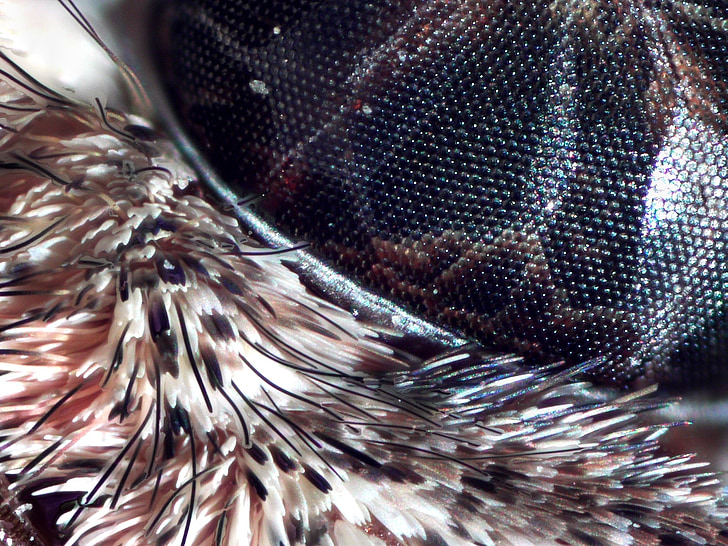

A better way of reducing Fresnel reflection losses would be profiling the fiber ends to create an anti-reflective microstructure (ARM). This method is also commonly referred to as the “moth-eye”. Moths are nocturnal insects with eyes that reflect little to no light. Images captured by electron microscopy has shown that moth eyes look like an array or grid of domes called ommatidia, as shown in the figure below.

A closeup image showing the ommatidia that make up a moth eye. Courtesy of Hippopx.

This forms a nanostructured film that creates an effective refractive index gradient between air and the material which reduces reflections. This inspired researchers at Fiberguide to develop an anti-reflective technology that replicates the effect of a motheye and reduces reflections to as low as 0.01% for some frequencies.

This technique is very advantageous as it does not require the use of any additional components or tools and can be directly applied to the fiber ends. However, it is good to note that the motheye microstructure can only be applied to hard materials such as fused silica. Nonetheless, other patterned microstructures exhibiting the same effects have been developed and used on soft materials such as silver halide.

In the following sections, we will discuss some of the techniques used to create anti-reflective microstructures on the ends of Silver Halide Fibers.

SMART Treatment

Special Microstructure Anti-Reflection Treatment or SMART for short is an etching technique employed to create a one-dimensional pattern (straight grooves or ridges equally separated) by cutting the fiber or scraping material off using a microstructured knife. The SMART technique improves the transmission by 16% when both ends of the fiber are treated.

ARM Imprinting Treatment

This is the simplest way of microstructuring a fiber and it is done by applying direct imprinting to the fiber end. This method replicates a two-dimensional structure of a moth eye by pressing a master against the end surface of the fiber. Because of the very small pattern (on the scale of nanometers), it is difficult to remove the master without damaging the replica. Luckily, this is not an issue for many materials. It is also expected that the fabrication process can be improved to avoid this issue. This technique improves the transmission of mid-IR laser radiation from 70% to 90% when both ends of the fiber are treated.

ARM Treatment by Femtosecond Laser Ablation

This is another microstructuring technique that creates a two-demensional pattern on the end surface of a fiber. The microstructure is fabricated by drilling holes using a powerful single pulse femtosecond laser. Studies report that the transmission is enhanced by 8% when one end of the fiber is treated. The main advantage of this technique is that it can be performed on even and uneven surfaces. It also requires fewer steps compared to the techniques discussed previously. Researchers are still developing this method to reach better transmission results.

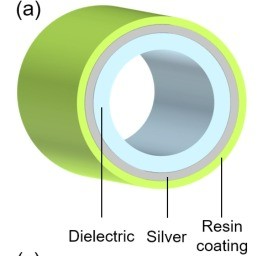

Hollow Waveguides

Standard optical fibers are made of 2 main parts: a core and a cladding which are typically made of glass or plastic materials. In the case of hollow waveguides (HWGs), the core is air, hence the name – hollow. Hollow waveguides are essentially light pipes made of plastic or metallic materials that also rely on total internal reflection (TIR) to propagate mid-IR radiation over a distance of a few meters. These fiber-like structures are excellent candidates for laser delivery because of their high-power thresholds, low absorption loss, flexibility, and no end reflection.

Since the core is air, these waveguides have no physical end surfaces at the input or the output thus completely eliminating Fresnel reflection losses. They can propagate mid-IR radiation with attenuation as low as 0.1dB/m and power transmission as high as 90%. In addition, art photonics reports that these waveguides can be engineered to support specific wavelengths or CO2 and CO radiations at the same time.

Studies have also shown that the transmission for a 700 µm hollow waveguide varies between 65% and 70% and for hollow waveguide with an inner diameter of 900 µm the power transmission ranges from 70% to 80%. This means that the power transmission can be enhanced by simply increasing the size of the waveguide.

However, hollow waveguides suffer from high bending sensitivity. Curving or bending the waveguide causes the lower-order modes to couple into the higher-order modes that are less confined or guided. In other words, power leaks outside of the cylindrical structure when the waveguide is bent giving rise to power loss. In fact, power loss due to bending is inversely proportional to the bending radius, which means that the smaller the loop or curve made with the hollow waveguide the greater the power loss. Empirical data has shown that the power transmission can drop to 50% for a bending radius of 10 cm for certain hollow waveguides.

Example of a beam delivery system: a circular hollow waveguide. Courtesy of ScienceDirect.

Bending the waveguide can also cause the distortion of the field distribution.

Beam Delivery Systems: Silver Halide (PIR) Fibers vs. Hollow Waveguides

After learning about the properties of these two beam delivery systems, you might ask: “Which technologies, HWG or PIR fibers, are better for CO2 and CO laser delivery?”. HWG and PIR fibers have advantages and disadvantages, so the answer is that the choice depends on the application. Hollow waveguides have very high transmission, up to 90% without any special treatment, and enjoy the advantage of not having physical end surfaces. This means that the transmission is not affected by reflection losses. However, if the application requires extensive bending of the waveguide, this delivery method becomes inefficient. Experiments conducted by art photonics to test the bending losses on HWGs have shown that the attenuation due to bending can be 3 times larger in HWGs than it is in PIR fibers.

On the other hand, Silver Halide (PIR) fibers are sturdy and can withstand bending effects better than hollow waveguides. Although transmission does not normally exceed 70% for PIR fibers, there are numerous ways of treating this type of fiber to improve the transmission to up to 90%.

Conclusion

The world’s second laser was a mid-IR solid-state laser. This invention opened possibilities for the development and integration of mid-IR lasers in a wide range of applications spanning different fields. Out of all the mid-IR lasers fabricated, CO2 and CO lasers remain some of the best lasers in this spectral range. Over the years, these lasers dominated many industries and fields including sensing, medical imaging, welding, marking, cutting, spectroscopy, and surgery.

CO and CO2 lasers are famous for their light-tissue interactions which make them excellent for laser surgery. These lasers can ablate skin down to single-cell precision with relatively little damage to the surrounding tissue and reduced side effects. The wavelengths of radiation emitted by CO and CO2 lasers do not penetrate deep into the skin which further reduces tissue damage. Despite these advantageous properties, the integration of CO2 and CO lasers in medical applications was only made possible when mid-IR fibers were invented almost a decade later.

This new technology allowed the medical world to benefit from CO2 and CO lasers. HWG and PIR fibers alike are some of the best mid-IR beam delivery systems. They offer great flexibility which is highly desired in laser surgery. In addition, they can support high power and a wide range of wavelengths while maintaining low absorption levels. Despite having some drawbacks like high bending sensitivity in the case of hollow waveguides or Fresnel reflection losses in the case of silver halide fibers, it is possible to minimize some of these effects and reduce power loss by treating the fiber or using it in applications where the bending radius is greater than the minimum bending radius.

If you’re interested in learning more about fiber microstructuring methods, please refer to the references below.

Sources:

- Mikhail K. Tarabrin, Andrey A. Bushunov, Andrei A. Teslenko, Tatiana Sakharova, Jonas Hinkel, Iskander Usenov, Torsten Döhler, Ute Geißler, Viacheslav Artyushenko, and Vladimir A. Lazarev, “Fabrication of an antireflection microstructure on AgClBr polycrystalline fiber by single pulse femtosecond laser ablation,” Opt. Mater. Express 11, 487-496 (2021), https://opg.optica.org/ome/fulltext.cfm?uri=ome-11-2-487&id=446868

- Sonata Adomavičiũtė-Grabusovė, Jonas Hinkel, Iskander Usenov, Alexander S. Novikov, Tatiana Sakharova, Torsten Döhler, Ute Geißler, Elena Feliksberger, and Viacheslav Artyushenko, “Microstructuring of the end-surface for silver halide polycrystalline fibers to suppress Fresnel reflection,” Opt. Mater. Express 12, 34-48 (2022), https://opg.optica.org/ome/fulltext.cfm?uri=ome-12-1-34&id=465630