Powder stream and directed energy deposition

Directed energy deposition (DED) is an innovative manufacturing technique. This method has a significant potential for the creation of novel materials. Technically, before the particles in the powder stream enter the melt pool during the directed energy deposition process, they briefly contact with the high-energy laser beam. In general, the addition of high-temperature particles to the melt pool will make it easier for powder particles to melt enough, enhancing the metallurgical quality. It is also anticipated that this will considerably improve the deposition efficiency of the DED process. In this article, we discuss the importance of heating and its effect on the behavior of laser beam on powder stream in DED.

To significantly increase the powder utilization rate during the deposition process and decrease the porosity of the sedimentary layer and the area of the dilution zone, increasing the interaction distance between the powder particles and the laser beam will significantly raise the temperature of the powder particles before they enter the melt pool.

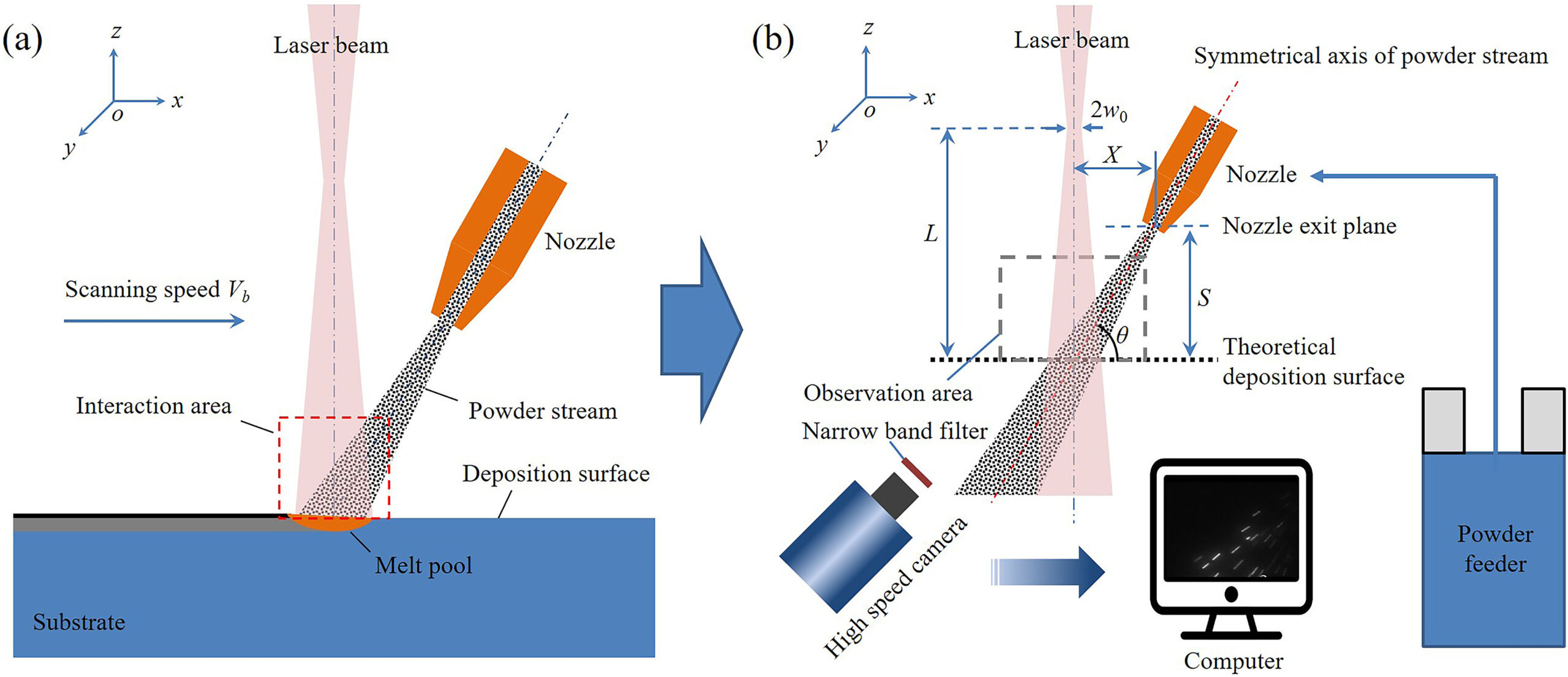

The importance of heating as well as heating behavior of the laser beam on the powder particles must therefore be understood in order to offer a scientific foundation for the best design and management of laser-powder interactions in directed energy deposition (see e.g., Figure 1). It is particularly challenging to quantify the rapid temperature evolution of a single particle in a laser beam because the powder particles move so quickly and the interaction time between the powder particle and the laser beam is so short.

Figure 1: Schematic of directed energy deposition process; Photo courtesy of Elsevier

Researchers mainly employed numerical simulation methods to represent the interaction between laser beam and powder particles. Their goal was to explore the importance of heating as well as the heating of powder particles under laser irradiation. Moreover, they investigated the heating behavior of laser beam on high-speed moving powders.

According to the calculations, the size, speed, and distance of the powder particles moving through the laser beam have a significant impact on the temperature of the particles. Small powder particles traveling through the laser beam at a slower speed may reach a maximum temperature that is higher than the melting point.

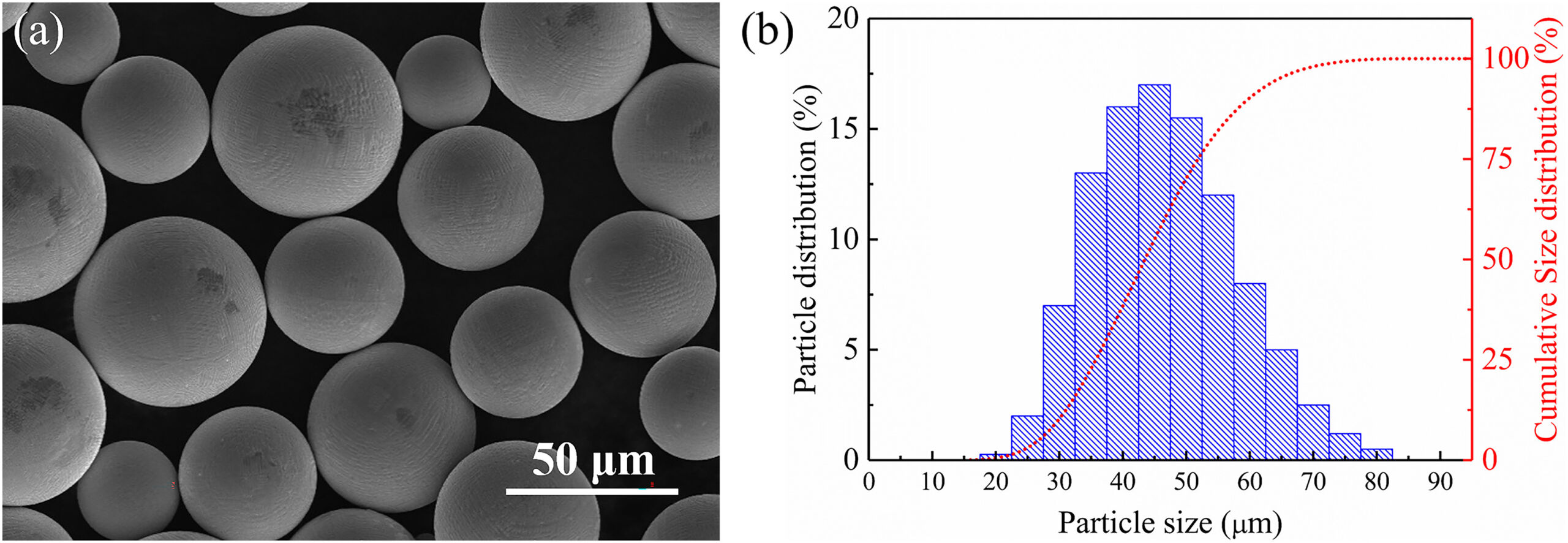

Figure 2: Powder stock considered for experiments; Photo courtesy of Elsevier

In order to systematically explore the nonlinear temperature evolution behavior of high-speed powder particles (Figure 2) in the laser beam while taking into account various process parameters, experimental characterisation and mathematical analysis have been undertaken by the researchers at Northwestern Polytechnical University (China) and Fraunhofer Institute for Laser Technology ILT (Germany). In the rest of this article, we discuss their findings.

Interaction between the laser beam and powder stream

The interaction region between the powder stream and laser beam is very small and the interaction duration is very brief during the DED process, before the powder particles enter the melt pool (Figure 1). An observation system for the powder-laser interaction process is set up (Figure 1) in order to evaluate the importance of heating as well as its effects on behavior of the laser beam on high speed feeding powder in the interaction area.

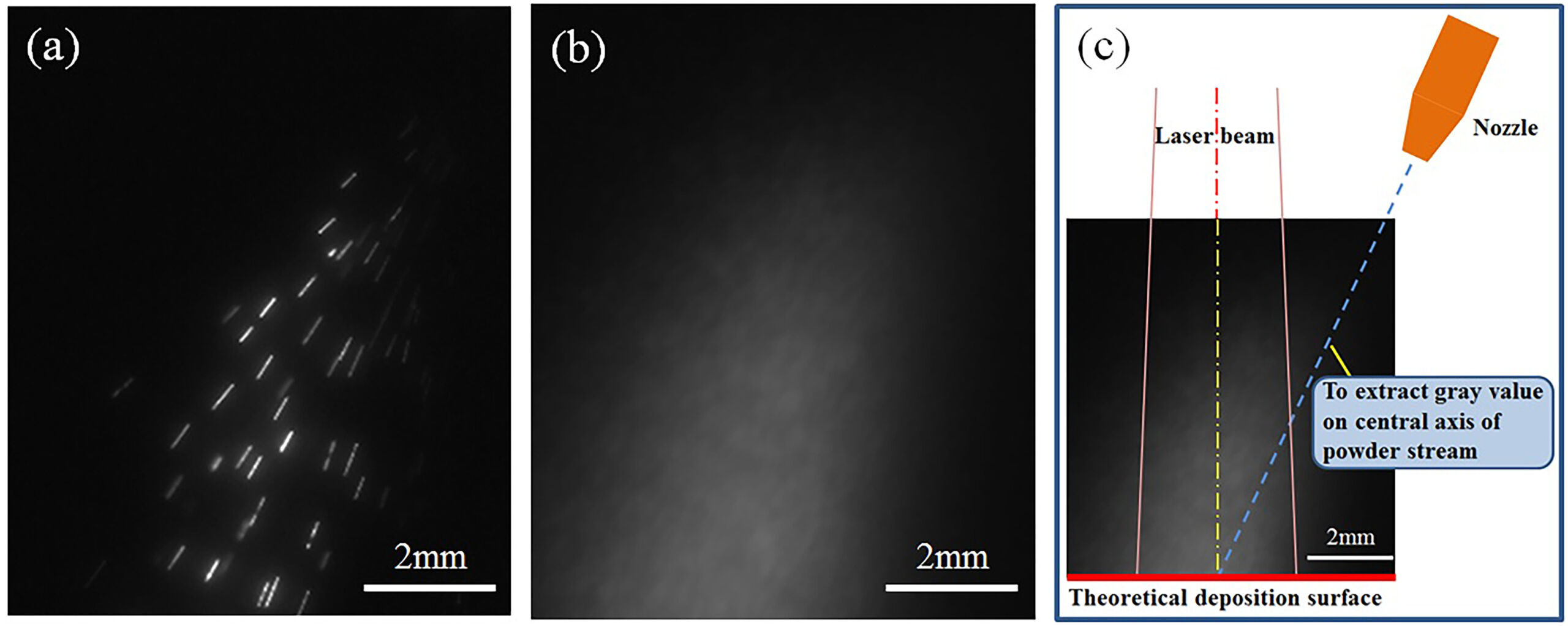

The camera may use the self-luminous energy of the heated powder particles as they encounter the laser beam to create a grayscale image of the powder stream; the higher the temperature, the larger the grayscale. Therefore, the gray image of the powder stream constituted of several moving particle groups (Figure 2) is acquired by utilizing a high-speed camera to continually capture the interaction area between the powder stream and laser beam.

To supply the powder to the laser irradiation area, a lateral powder feeding nozzle is employed to create a powder stream with a specified incidence angle. The only aspect of the interaction between the powder particles (Figure 2) and the laser that occurs before they reach the deposited surface is the subject of this work.

Figure 3: Image of powder stream image; Photo courtesy of Elsevier

The substrate is not positioned at the theoretical deposition position under the laser beam in the observation tests in order to exclude the influence of the high brightness melt pool and the interference of the rebound powder particles (Figure 2) from the substrate.

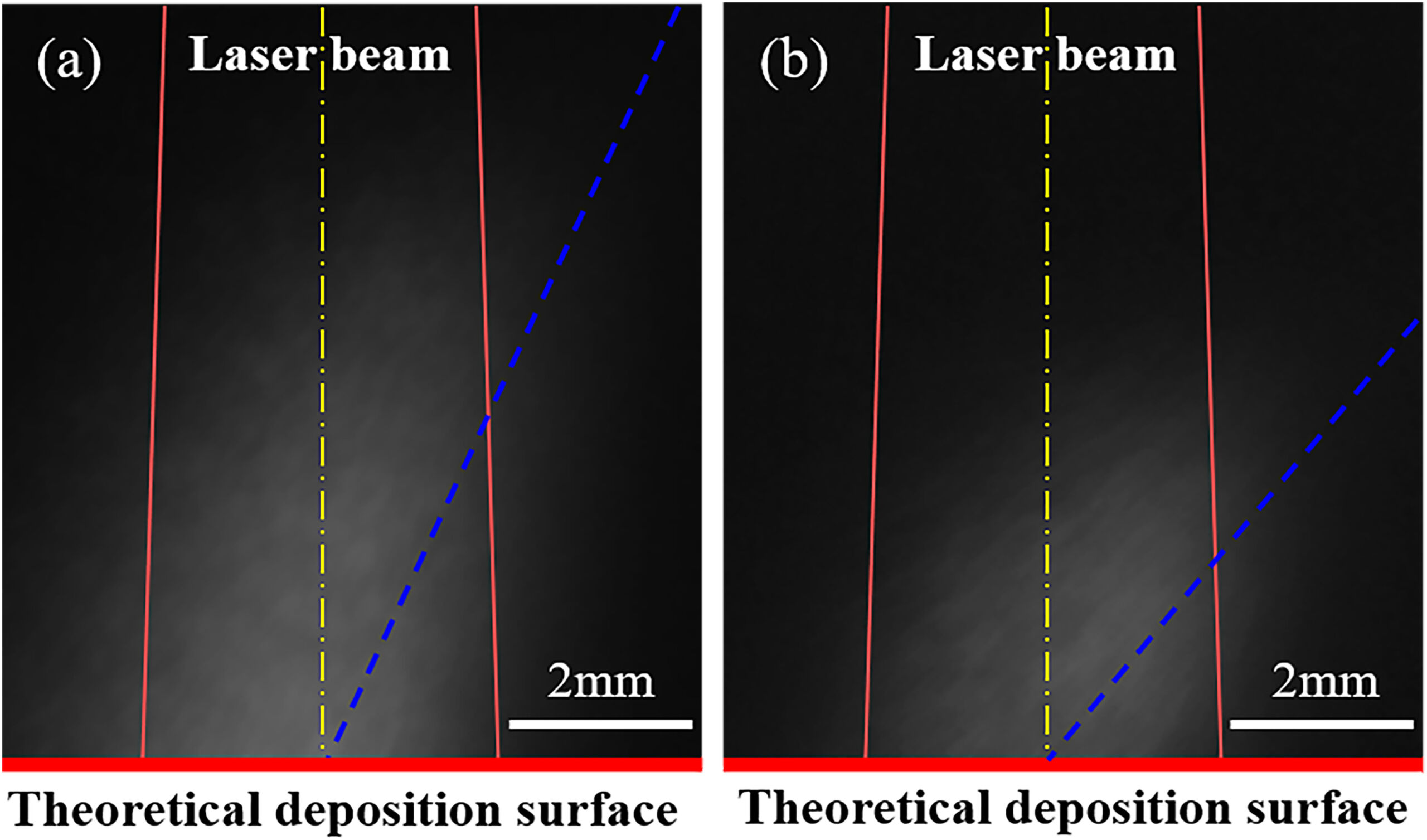

The lateral nozzle then injects the powder toward the laser beam at a specific incidence angle (Figure 3) after the powder feeder has first transported the powders to it through the carrier gas. To reduce the impact of powder stream reflection and dispersed laser light during the shooting process, a narrow-band filter is placed in front of the high-speed camera lens. To acquire the grayscale evolution law of the powder stream picture, the grayscale image of the powder stream under the laser-powder interaction is supplied to a computer for image processing and analysis. Moreover, a summary of the properties of the material used in their study can be found in Table 1.

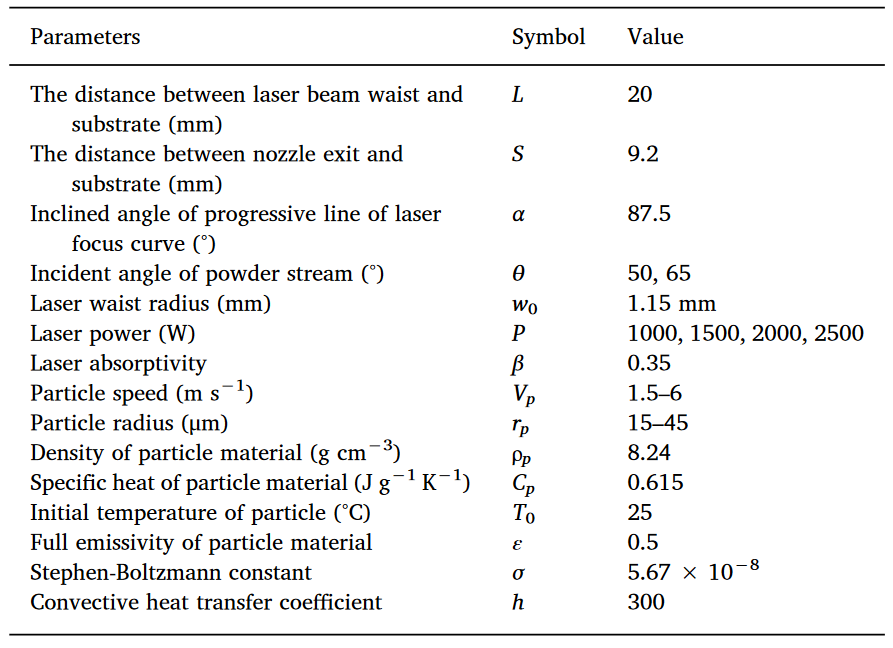

Table 1: Parameters used in the calculation; Table and information courtesy of Elsevier

Results and studying the importance of heating

In this article, we discussed the novel works done by the researchers at Northwestern Polytechnical University (China) and Fraunhofer Institute for Laser Technology ILT (Germany). Here are a summery of the results reported by their research group.

High-speed photography was used to capture gray photos of the laser-heated powder stream at high temperatures. The gray value was then rectified by taking into account the diverging characteristics of the powder stream to correlate to temperature change. A brand-new experimental technique was created to characterize the powder stream’s temperature evolution law under laser irradiation. In the meantime, the results of the mathematical analysis of the high-speed particle temperature evolution in laser beam were in good agreement with the findings of the experiment.

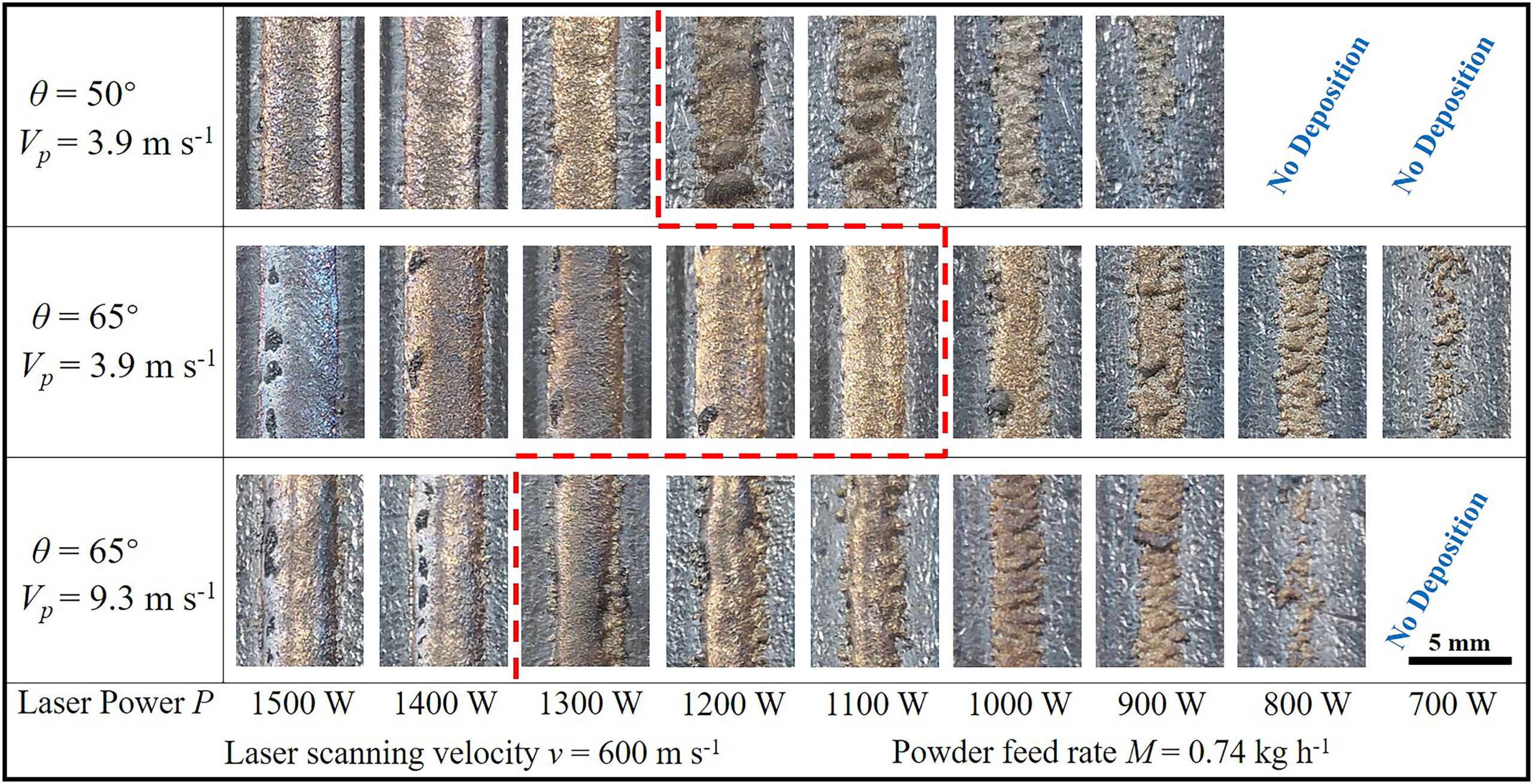

The powder particles that cross the center axis of the laser beam and land close to the edge of the laser spot on the theoretical deposition surface (Figure 4 and Figure 5) have the highest incidence temperature due to the effects of the laser energy distribution along the moving trajectories of the powder particles.

The increasing interaction effect between the laser beam and the powder stream can efficiently increase deposition quality and conserve energy, according to single-pass deposition tests. With a lower laser power, the deposition quality can be improved due to the bigger powder stream incident angle and slower powder stream speed, which improve the laser-powder interaction and temperature of the powder reaching the deposition surface (Figure 4 and Figure 5).

Figure 4: Gray image of powder stream at different angles; Photo courtesy of Elsevier

At the end, we list a few take-home messages of their research:

- The powder particles that cross the center axis of the laser beam and land close to the edge of the laser spot on the theoretical deposition surface have the highest incidence temperature due to the effects of the laser energy distribution along the moving trajectories of the powder particles (Figure 2).

- The increasing interaction effect between the laser beam and the powder stream can efficiently increase deposition quality and conserve energy, according to single-pass deposition tests.

- With a lower laser power, the deposition quality can be improved due to the bigger powder stream incident angle and slower powder stream speed, which improve the laser-powder interaction and temperature of the powder reaching the deposition surface.

Figure 5: A few results of single-pass deposition experiments; Photo courtesy of Elsevier