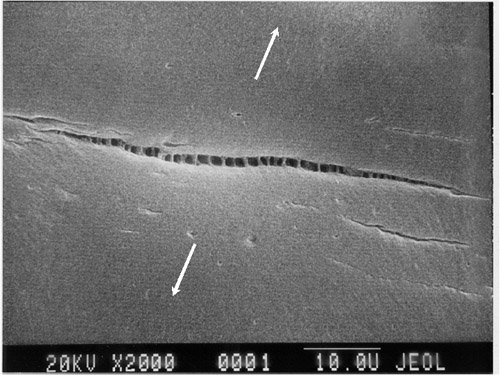

Delayed fractures in solids following application of stress poses problems in predicting the safety of the materials. Picture courtesy of Polymer Science & Engineering.

A team of researchers from the Wageningen University in the Netherlands has devised a new method of imaging solids as stress is applied to them. This method, called laser speckle strain imaging, reveals local deformations in the localized prefracture deformation zone. As this zone expands, the probability of the solid failing increases. In the future, laser speckle strain imaging can be used to determine the safety of solids when stress is applied.

What motivated such research?

In the study of mechanics, stress and strain are two crucial concepts. Stress measures the internal forces that two materials exert on each other. In experiments, a specific stress is loaded and applied to a particular solid and the behavior of the solid is observed. The stress at which the solid buckles, or catastrophically fails, is referred to as the critical fracture stress. However, the solid can still fail over time if a stress less than the critical fracture stress is loaded.

The delay in time between the application of stress and the fracture can vary greatly, from seconds to years. Therefore, prediction of failure is difficult. This poses problems for evaluating safety of materials exposed to high levels of stress. Consequently, the researchers were motivated to create a method for determining damage done to solids. This imaging technique could become a vital tool in material science as engineers work to determine the durability and longevity of engineered materials.

How does Laser Speckle Strain Imaging work?

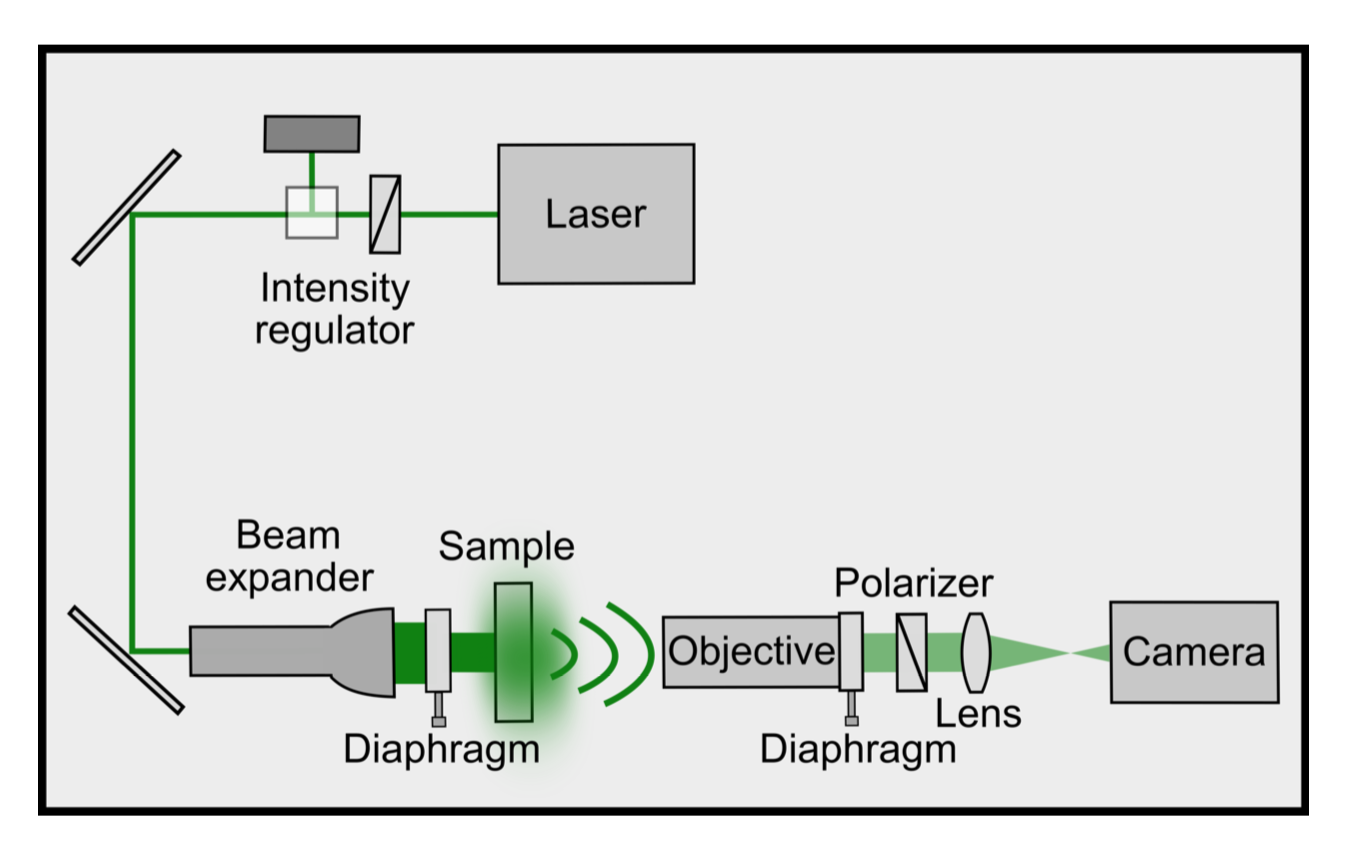

This image shows a top view schematic of the equipment used for laser speckle strain imaging. Courtesy of ScienceAdvances.

Laser speckle strain imaging is similar to diffusing wave spectrometry. Prior to experimentation, the sample is embedded with TiO2 nanoparticles. Then, the sample is illuminated with a 1.5 Watt light beam at a wavelength of 532 nanometers. The photons of the beam scatter because of the nanoparticles. The path length differences of photons causes interference in the scattered signal. A high-speed camera records the signal using a metal-oxide semiconductor chip.

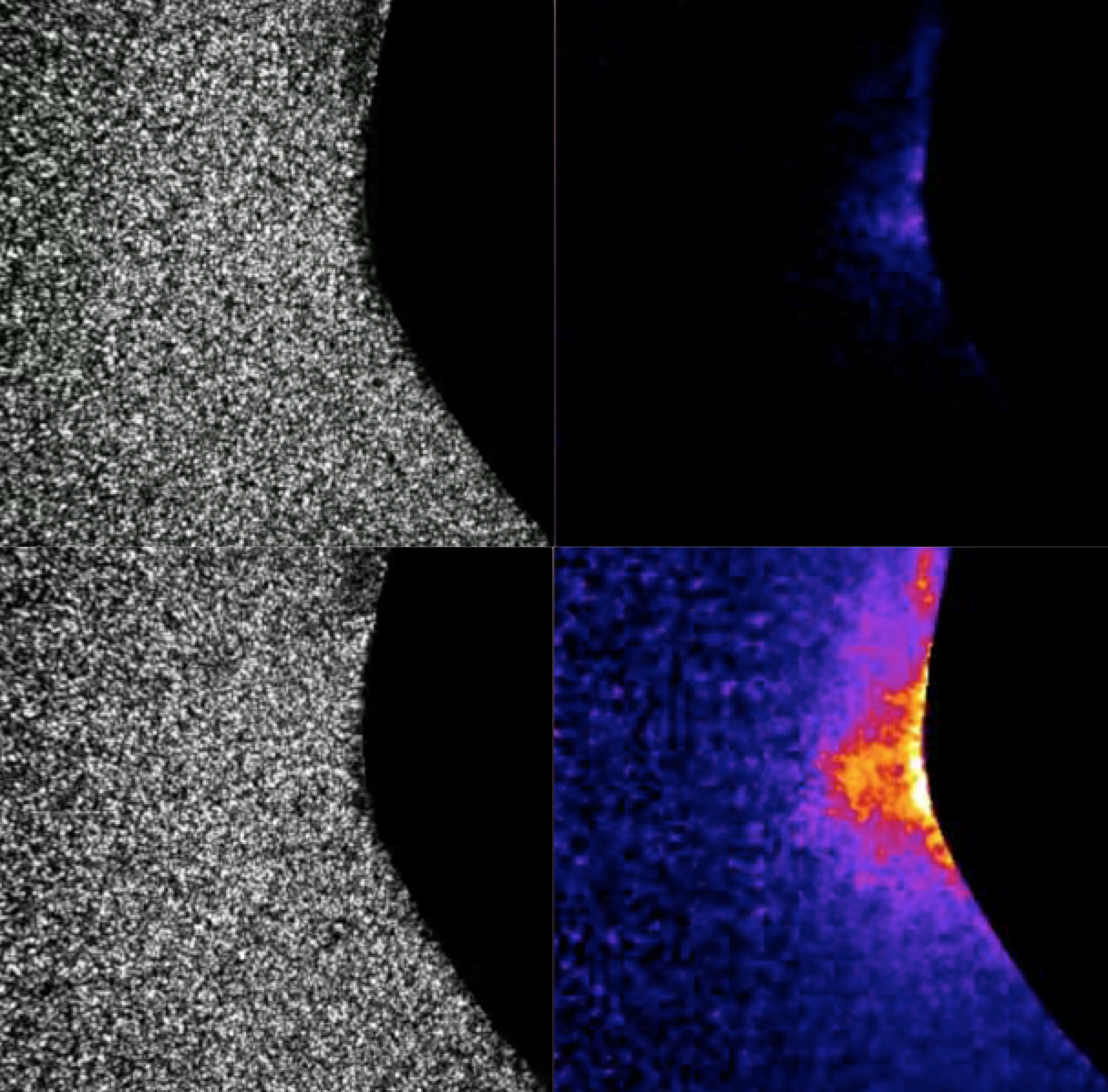

The image produced by this camera is a speckled pattern of bright and dark spots. Visible changes can be quickly detected after stress is applied, as shown in the images below. Analysis of images determines relative damage to the samples. Further analysis allows for computation of spatial and temporal profiles.

Side-by-side analysis of these two images shows damage inflicted to the solid. The bottom images were directly before fracture occurred. The images on the right were achieved by analyzing internal dynamics of the sample based on intensity. Courtesy of ScienceAdvances.

How were experiments set up?

All experiments were done using elastomers made of Polydimethylsiloxane (PDMS) silicone. As stated above, the elastomers were embedded with TiO2 nanoparticles to allow for photon scattering. Additionally, the samples all had a measured Young’s Modulus of 1.1 ± 0.1 MPa. Experiments were done resulting in 25% and 30% strain of the polymer by placing the sample in a strain-controlled tensile tester. Once the sample was in place, it would be exposed to the light beam, which would determine deformations.

The Results

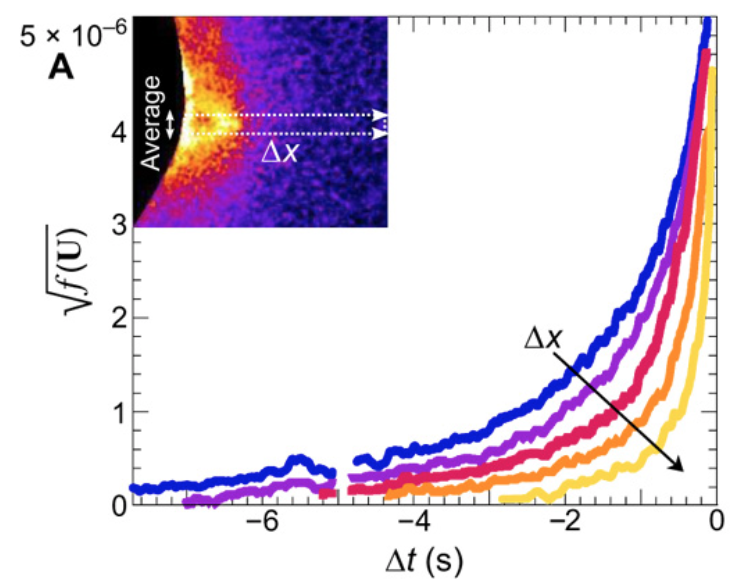

To analyze the results of the experiment, researchers computed the local differential strain intensity over time. In addition, the processed images taken from the experiments were analyzed as well. The combination of these two methods of analysis can be seen in the image below.

The graph above displays the local differential strain intensity over time. A fracture nucleated at time equal to zero. As shown, the local differential strain intensity increases exponentially until the solid fractures. Courtesy of ScienceAdvances.

Ultimately, the results showed that a field of small-scale deformations occurred when stress was applied to the sample. Thanks to laser speckle strain imaging, this field can be detected before any signs of damage are visible using the naked eye or a light microscope. Over time, the site of applied stress gets weaker, indicated by the change in colors shown in previous images. Eventually, fracturing occurs. All the results combined help to prove the erosion theory. This theory predicted that delayed-crack nucleation occurred thanks to a cascade of molecular damage processes. The images from the experiments showed that these molecular damage processes would start at the site of applied stress. Unfortunately, the resolution of this type of imaging does not allow for the viewing of bond rupturing.

What is the significance of these findings?

The experiments described above are only a beginning step. Laser speckle strain imaging can still be improved on. For example, the resolution can be improved by the use of a more specialized camera. Additionally, the experiment only tested one specific type of soft polymer; future experiments should employ a wider range of samples to see the effect of applied stress to materials over time. However, the significance of this imaging technique is great. With more research and improvements, laser speckle strain imaging can be used to monitor the state of objects exposed to large amounts of stress. It would be able to warn researchers of an imminent fracture, allowing for the necessary safety measures to be taken. It can also be used to test the safety and durability of new ultra-tough engineered materials. Laser speckle strain imaging can have a great impact on the field of material science in the near future.

To read more about this experiment, the paper can be read here.