Laboratory tests and analysis are a vital part of identifying diseases. New techniques use the WCM to diagnose diseases from inside the body, without traditional sample collection. Image courtesy of Pixabay.

Researchers from the Harbin Institute of Technology at Shenzhen and Shanxi University have created a new configuration for waveguide connected microdisks (WCM). Their method could significantly reduce production costs, facilitating commercial development of WCMs.

A simply fabricated biosensor of this nature will have a profound impact on the cost of in-vivo diagnostics. In-vivo diagnostic tools are more accurate than other methods, but researchers have run into problems adopting them on a large scale. These problems include keeping an accurate sensor that also has a low cost fabrication and is safe for use in the human body.

The research paper focuses on how prior fabrication techniques for WCMs can be simplified without sacrificing sensitivity or size. Typical methods of coupling light in these configurations are time consuming, and too expensive for commercial production. The researchers use a technique called “end-fire injection” to couple light directly to the WCM, sidestepping the cumbersome parts of production.

What are waveguide-connected microdisks, and what makes them costly?

Silicon microdisks are platforms made to transport waveguide sensors safely into the body to perform in-vivo diagnostics. They are a useful medium since they are biocompatible (does not provoke adverse reactions from the body). In addition, they are small enough to be injected without needing a invasive procedures, unlike larger sensory methods. These microdisks are typically based on whispering gallery resonators, which means their concavity enhances light signals that enter it.

The WCM receives signals given off by proteins, cells and viruses that may indicate diseases, in order for diagnostic professionals to interpret the data. WCMs must be sensitive to temperature changes and nanoparticles, as these are common forms of disease biomarkers. Most prior research focuses on enhancing the sensors’ accuracy which makes for effective tools in a research setting. However, typical WCM fabrications are commercially impractical because of their cumbersome coupling mechanisms.

Existing methods use an evanescent coupling configuration to link the waveguide and microdisk’s resonator. In this configuration, the waveguide needs extremely precise alignment. The only current way to manufacture this setup is with electron beam lithography. Precise lithography like this is costly, not portable and difficult to use repeatedly. To use microdisks in commercial applications, researchers need a portable, low cost coupling mechanism to get light into the microdisk easily.

How did the researchers simplify WCM coupling?

End-fire injection gets its name because the light undergoes an injection and rejection process after entering the WCM. This causes fluctuations in the reflection and transmission spectrums that allowed the researchers to couple light without electron beam lithography. The waveguide is directly attached to the end of the microdisk, at a normal incident angle. Intuitively, the light from this waveguide setup would reflect off the disk because of its perpendicular angle in relation to the disk. However, the resonance emitted from the microdisk changes this effect.

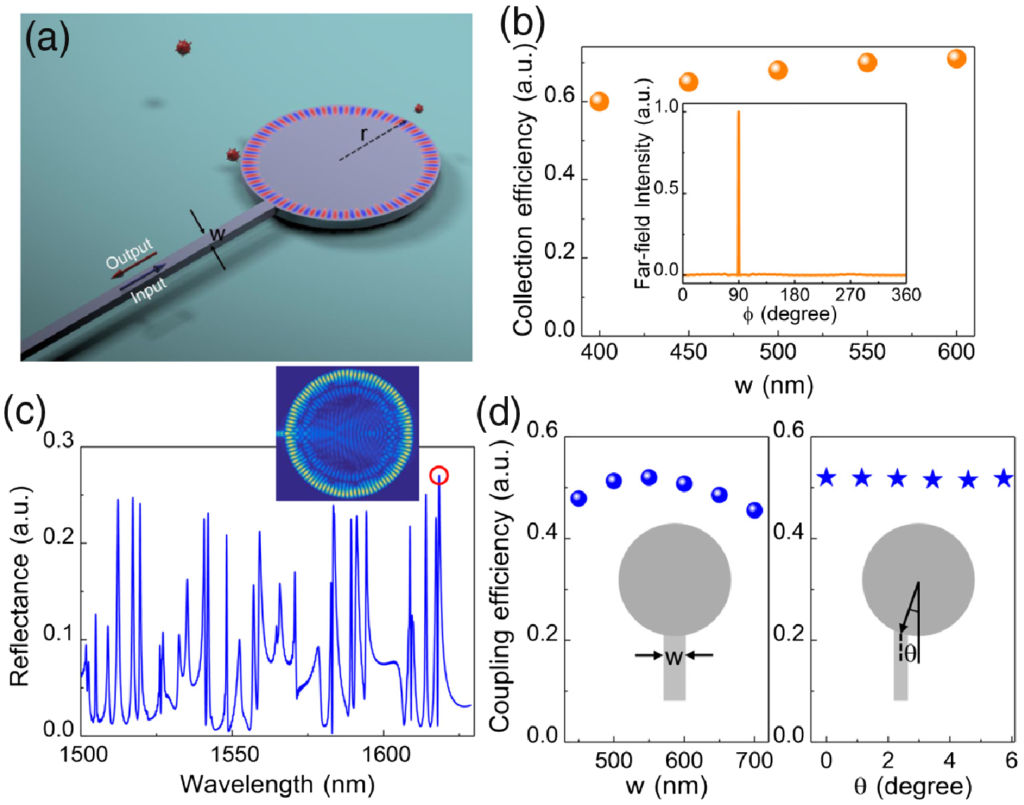

Figure (a) on the top left shows the configuration of the waveguide and microdisk. Figures (b) and (c) outline the unidirectional emission and the reflection spectrum of the waveguide respectively. Figure (d) shows a relationship between input coupling and waveguide width, as well as reflection coefficient and tilt angle.

The resonator’s reflection spectrum displays a series of peaks, which correspond to changes in the waveguide’s transmission spectrum. The laser passing through the waveguide is made into a coherent perfect absorber that can sense resonant waves from the microdisk. The researchers then use the interaction between the two spectra to read into the light’s reaction to deviations. This simple modification allows the WCM to pick up biomarkers.

The researchers experimented with the laser’s response to various fabrications and conditions, in order to verify the method was comparable to other WCM configurations. The results displayed a high Q factor, comparable to competing fabrications as well as resonance dips that respond in a similar fashion. The resonance dips matched almost exactly with their mathematical prediction in the first set of figures.

Is the new fabrication as accurate as other WCMs?

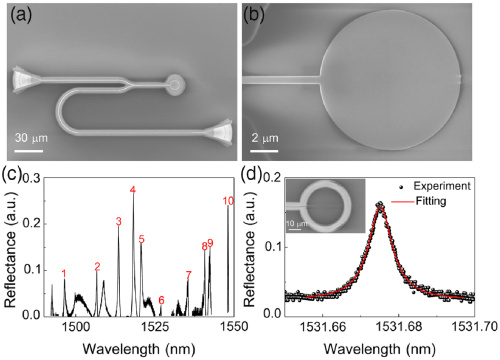

Figures (a) and (b) are a low and high-resolution views of the waveguide connected microdisk. Figure (c) is a graph of the reflection spectrum. Figure (d) is a view of the waveguide’s q-factor using the experimental method.

The researchers fit a y-splitter to one end of the waveguide in a WCM setup. Then they fit the Y-splitter’s two arms with grating couplers to track the reflection spectrum. They then relayed a polarized tunable laser through one of the y-splitter’s arms. Light passed through the junction effectively, with minimal path loss. The splitter then divided the resonant waves picked up by the microdisk. Each grating absorbed half of the resonant waves, where researchers analyzed its efficiency. They compared it with the y-junction’s split ratio to map the reflection spectrum (pictured in figure C).

The resonance dipped as it should in the presence of nanoparticles. The incident light’s wavelength stretched corresponding to the dips in resonance, confirming the sensor was reacting properly. The researchers tested multiple WCM configurations to ensure that the changes in resonance were not entirely dependent on the microdisk design. They used multiple channeling waveguides to map each respective reflectivity spectrum, with the figure D representing the respective Q factors.

The next step was testing the system’s sensing capabilities in a hands-on experiment. A nanoparticle with a radius of 30 nm caused the wavelength to grow wider by about 30pm. Environmental temperature’s effect on these readings can be minimized by using a parallel microdisk. The waveguide’s sensitivity values of these changes were equal to, and in some cases better than typical WCMs. Detectivity ranged from 40-100nm, whereas the limits for a standard mode shift method are 30nm. For the most part, there are no significant downsides in the function of this fabrication in comparison to other WCMs.

Conclusion

In short, the researchers made leaps and bounds towards an affordable diagnostics tool, specifically in the field of deadly diseases. In addition, the method preserves sensitivity, and in some cases improves it over existing ones. Since the configuration uses no parts smaller than 500 nanometers it can be made with cost-efficient lithography techniques. Simple shadow masking methods can fabricate waveguide connected microdisks with this coupling configuration.

A simpler coupling method entails lower production/labor cost and quicker fabrication time. On top of that, an increase in detectivity will be useful for cancer diagnostics. Detecting diseases, especially cancer, makes up a huge segment of the diagnostics market. Subsequently, a cost reduction could possibly drive demand. These factors could encourage the production of a commercial microdisk that for use firsthand diagnostics, at the point of care. An overall proliferation of microdisks could make for more efficient diagnostics, and quicker paths to treatment for patients.