Metal Vapor Lasers (MVLs) stand at the cutting edge of photonics, offering unmatched precision and efficiency in a range of scientific and industrial applications. From material processing to medical therapies, MVLs are reshaping how engineers and scientists use the power of coherent light. This guide delves into the core operations, recent innovations, and emerging applications of metal vapor lasers, providing a comprehensive overview that equips professionals with the knowledge to push the boundaries of what’s possible in their fields. Join us as we explore MVLs, where every pulse of light paves the way for new discoveries.

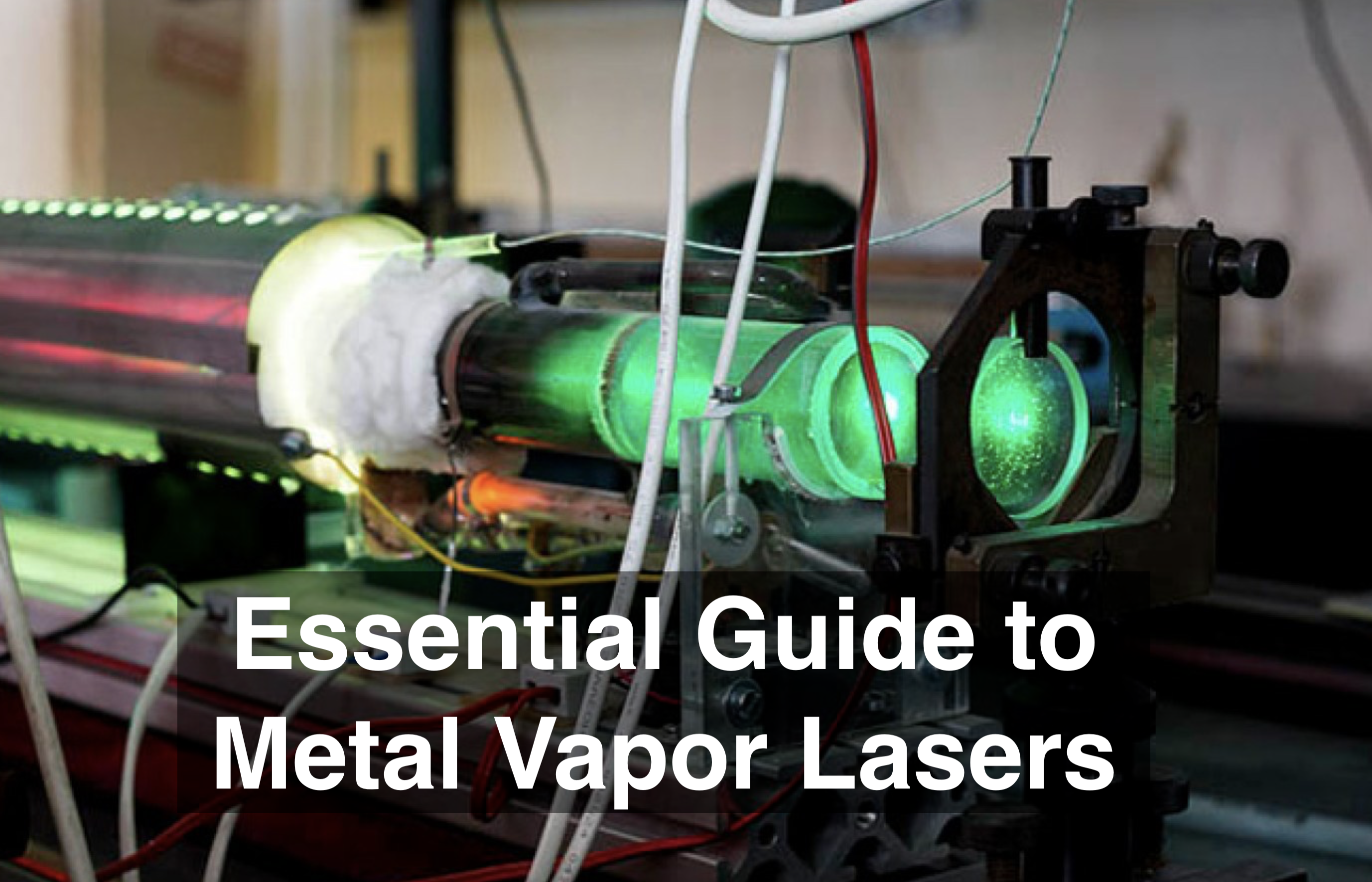

Metal Vapor Laser at Work. Image courtesy of International Business Times

Introduction

Metal Vapor Lasers (MVLs) represent a specialized category of gas lasers where the active medium is a metal vapor. Known for their high-powered output and ability to emit light at wavelengths not commonly achievable by other lasers (511 nm / 578 nm (copper) and 628 nm (gold)), MVLs have become indispensable tools in a variety of high-precision fields. Their applications range from micro-machining and isotopic separation to medical procedures and advanced research in photonics.

The versatility and efficiency of metal vapor lasers make them pivotal in both scientific research and industrial applications. In scientific settings, they enable precise measurements and unique interactions with matter, while industrially, they are crucial for cutting, engraving, and other material processing tasks that require exceptional accuracy.

This article aims to dissect the operational principles, technological advancements, and the expanding scope of applications of metal vapor lasers. By consolidating current knowledge and highlighting emerging trends, we provide engineers and scientists with a comprehensive resource that not only informs but also inspires further innovation in the use of MVL technology.

Are you in the market for a Metal Vapor Laser? Check out marketplace where we have a dedicated category for MVLs.

Fundamental Principles of Metal Vapor Lasers

Metal Vapor Lasers operate on the principle of optical amplification through the stimulated emission of radiation, where the lasing medium consists of metal vapors. These lasers are distinct for their ability to generate coherent light in the visible and ultraviolet spectra, offering unique characteristics crucial for specialized applications.

Basic Operation Principles: At the core of an MVL’s operation is the electrical excitation of metal atoms, which are vaporized in a high-temperature environment. When these metal atoms return from an excited to a lower energy state, they emit photons, producing a laser beam. The process is sustained by a continuous supply of energy, typically from an electrical discharge or another high-energy source.

Types of Metal Vapors Used and Their Properties: Common metals used in MVLs include copper, gold, and silver, each chosen for specific wavelength emissions and properties. Copper vapor lasers, for example, emit green (511 nm) and yellow (578nm) light and are noted for their high output of coherent radiation. Gold and silver vapor lasers emit in the red (628 nm) and blue regions, respectively, and are used when these particular wavelengths are needed for precision tasks in medical and technological fields.

Key Components of MVLs

- Resonator Design: The resonator in an MVL determines the efficiency and quality of the laser beam. It typically consists of a pair of mirrors placed at each end of the laser tube that reflect the light back and forth, amplifying it with each pass.

- Vapor Generation: Achieving the correct metal vapor concentration involves heating the metal to a precise temperature, which is crucial for optimal laser performance. This is often managed through controlled heating elements or radiofrequency induction.

- Power Supply: The power supply for an MVL must be capable of delivering consistent, high-voltage electricity to maintain the necessary energy levels for vaporization and excitation of the metal atoms.

By understanding these fundamental principles, engineers and scientists can optimize MVL configurations for specific applications, ensuring maximum efficiency and effectiveness in their operations.

Advancements in Metal Vapor Laser Technology

Metal Vapor Lasers (MVLs) have seen substantial advancements that enhance their performance and extend their applications. These improvements focus on optimizing power output, efficiency, and beam quality while reducing size and energy consumption.

Recent Technological Improvements: Technological enhancements in MVLs include improved thermal management and advanced optical coatings, which contribute to longer operational lifespans and more stable outputs. Innovations in pulse modulation techniques also allow for finer control over laser operations, enhancing precision in applications such as microfabrication and medical procedures.

Innovations in Laser Design and Efficiency: Advancements in materials and electronic controls have led to more compact and efficient MVL designs. Use of composite materials in laser tubes supports higher operational temperatures and pressures, improving vaporization efficiency. Additionally, modern MVLs incorporate adaptive control systems that optimize performance based on real-time feedback, enhancing energy efficiency and output quality.

Comparative Analysis with Other Lasers: MVLs are preferred in scenarios requiring high peak powers and specific wavelengths, such as in photodynamic therapy and precision machining, where they outperform solid-state and fiber lasers. However, they typically require more maintenance and have a larger footprint, which can be a disadvantage compared to more compact and low-maintenance laser types like fiber and diode lasers.

These ongoing advancements ensure that MVL technology remains a vital tool for scientists and engineers, combining unique capabilities with enhanced operational efficiencies.

Applications of Metal Vapor Lasers

Metal Vapor Lasers (MVLs) are utilized across diverse fields due to their precise and powerful capabilities. These lasers play a crucial role in material processing, lithography, and medical applications, among others.

Material Processing and Lithography: In material processing, MVLs are pivotal for tasks requiring high precision such as cutting, engraving, and micro-machining. Their ability to produce consistent, high-quality results makes them ideal for manufacturing intricate components. In lithography, copper vapor lasers, known for their fine resolution and depth control, are used to create detailed patterns essential in semiconductor manufacturing.

Medical Applications: MVLs have transformed medical treatments by providing non-invasive solutions for delicate surgeries, particularly in ophthalmology and dermatology. Their precise targeting allows for minimal damage to surrounding tissues, enhancing patient recovery times and surgical outcomes.

Case Studies in Scientific Research: Recent studies have demonstrated the use of gold vapor lasers in advancing cancer treatment research, where their specific wavelength helps in accurately targeting cancer cells without affecting healthy tissues. Another study showcased silver vapor lasers used in environmental monitoring to detect pollutants at very low concentrations.

Emerging Applications: New fields are continually adopting MVL technology. One emerging application is in the field of quantum computing, where MVLs manipulate quantum bits with high precision, promising significant advancements in computing speed and security.

Challenges and Solutions

Metal Vapor Lasers (MVLs) face several operational and maintenance challenges that affect their performance and longevity.

Common Technical Challenges: MVLs require high maintenance due to their complex setup and sensitive components. Key issues include alignment difficulties, thermal instability, and rapid degradation of laser materials under intense operational conditions. These factors can lead to decreased efficiency and increased downtime.

Solutions and Workarounds: Engineers have developed several solutions to mitigate these challenges. Enhanced alignment techniques and improved thermal management systems help maintain stability and extend the lifespan of MVL components. Advances in material science have also led to more durable components that withstand harsh operational environments better.

Future Challenges and Research Areas: Looking ahead, MVL technology faces challenges in reducing energy consumption and increasing integration into portable devices. Research is ongoing to develop more energy-efficient systems and miniaturized designs that maintain performance while being more adaptable to various applications.

These developments and continuous research efforts aim to overcome existing limitations and unlock new potentials for Metal Vapor Lasers in scientific and industrial fields.

Safety and Regulatory Considerations

Operating Metal Vapor Lasers (MVLs) requires strict adherence to safety and environmental protocols to prevent risks and ensure compliance.

Safety Measures: When operating MVLs, it’s crucial to implement robust safety measures. Protective eyewear is mandatory to shield against harmful radiation. Operators must also use controlled environments that prevent unauthorized access and minimize exposure to laser beams. Regular training and safety audits help maintain high standards of operation.

Compliance with International Standards: MVLs must comply with international laser safety standards such as those set by the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI). These standards dictate the design and usage guidelines to mitigate risks associated with laser operations.

Environmental Impact: The environmental impact of MVLs, particularly concerning the disposal of hazardous materials used in vapor generation, requires careful management. Proper disposal methods and recycling protocols are essential to minimize ecological footprints. Additionally, advancements in laser technology focus on reducing power consumption and emissions to promote a more sustainable application of these devices.

Adhering to these safety and regulatory frameworks not only ensures the safe operation of MVLs but also supports their sustainable integration into various industries.

Future Directions

Metal Vapor Lasers (MVLs) continue to evolve, promising significant advancements in photonics and beyond.

Predictions for Future Developments: Technological developments in MVLs are expected to focus on increasing efficiency, reducing size, and enhancing beam quality. Innovations such as solid-state pumping and advanced optical materials may revolutionize the design and functionality of MVLs, leading to more robust and energy-efficient systems.

Impact on Various Industries: Advancements in MVL technology are poised to have a profound impact across multiple industries. In healthcare, improved MVLs could lead to more precise and less invasive surgical techniques. In manufacturing, enhanced precision and efficiency can drive the adoption of MVLs in finer, more complex material processing tasks. Additionally, the improvements in MVL technology could enhance data storage and communication technologies by enabling faster and more reliable optical data transmission.

Role of Interdisciplinary Collaboration: The advancement of MVL applications heavily relies on interdisciplinary collaboration. Combining expertise from physics, engineering, materials science, and industry-specific knowledge leads to innovative solutions and broader adoption of MVL technology. Collaborative efforts between academia and industry are crucial in translating laboratory innovations into practical, commercially viable technologies.

Conclusion

This article has explored the intricate dynamics of Metal Vapor Lasers (MVLs), from their fundamental principles to cutting-edge advancements and diverse applications. MVLs demonstrate significant versatility and precision, making them indispensable in fields ranging from material processing to medical treatments.

As the technology evolves, we anticipate further enhancements that will expand their utility, improve operational efficiencies, and reduce environmental impacts. The future of MVL technology is not just about advancements in the lasers themselves but also in how they integrate into broader technological and industrial landscapes.

We encourage ongoing research and innovation within this field. By pushing the boundaries of current scientific understanding and technological limits, the global research and engineering communities can unlock new possibilities and applications for MVLs. Continued interdisciplinary collaboration will be key to overcoming existing challenges and realizing the full potential of Metal Vapor Lasers.

References

Use the following resources to further your understanding of Metal Vapor Lasers.

- ScienceDirect. (n.d.). Collection of Articles and Chapters on Metal Vapor Lasers. Retrieved July 11, 2024, from https://www.sciencedirect.com/topics/physics-and-astronomy/metal-vapor-lasers

- Coutts, D. W. (2005). Lasers | Metal Vapor Lasers. In Encyclopedia of Modern Optics (Vol. 4, pp. 460-467). https://doi.org/10.1016/B0-12-369395-0/00847-2

- Potter, K. S., & Simmons, J. H. (2021). Chapter 7 – Optical gain and lasers. In Optical Materials (Second Edition) (pp. 369-428). https://doi.org/10.1016/B978-0-12-818642-8.00007-7

- Duarte, F. J. (2003). Chapter 9 – Lasers and Their Emission Characteristics. In Tunable Laser Optics (pp. 177-201). https://doi.org/10.1016/B978-012222696-0/50056-9

- Coutts, D. W. (n.d.). Lasers | Metal Vapor Lasers. In Encyclopedia of Modern Optics. https://doi.org/10.1016/B0-12-369395-0/00847-2

- Coutts, D. W. (2005). Lasers | Metal Vapor Lasers. In Encyclopedia of Modern Optics (pp. 460-467). https://doi.org/10.1016/B0-12-369395-0/00847-2

- Ready, J. F. (1997). Chapter 3 – Practical Lasers. In Industrial Applications of Lasers (Second Edition) (pp. 66-130). https://doi.org/10.1016/B978-012583961-7/50005-3