Near-Infrared Spectroscopy (NIR) offers important advantages in analytical chemistry, particularly in process monitoring and quality control across various industries. This paper details the operational principles, methodologies, and significant advancements in NIR spectroscopy, emphasizing the role of fiber optic probes in facilitating real-time, remote measurements. It provides a critical analysis of NIR applications in sectors such as pharmaceuticals, food safety, and materials science, underscoring the integration of Process Analytical Technology (PAT) to optimize production processes and ensure compliance with industry standards.

Illustration of a fiber optic probe in action, showcasing the transmission of near-infrared radiation for spectroscopic analysis. Image courtesy of art photonics, GmbH.

Introduction

Near-Infrared Spectroscopy (NIR) is a robust analytical technique that harnesses the near-infrared region of the electromagnetic spectrum for material characterization and quality control. As a non-destructive, versatile method, NIR spectroscopy is integral to contemporary industrial and laboratory practices. In this white paper, we look into the principles of NIR spectroscopy, exploring its physical basis and the methods employed for different sample types, such as reflection spectroscopy for solids and transmission spectroscopy for liquids.

This work has been made in partnership with art photonics, GmbH - offering 20 years of experience in developing specialty optical fibers and solutions.

Further, we discuss the instrumentation advancements, particularly the development and application of fiber optic probes that enable remote, real-time monitoring of processes under various environmental conditions. We also covers the significant applications of NIR spectroscopy across diverse sectors including pharmaceuticals, food quality, and materials science, highlighting its role in enhancing process analytical technologies (PAT) and ensuring stringent quality standards. By integrating detailed technical discussions with practical insights, we aim to furnish scientists and engineers with a deeper understanding of NIR spectroscopy’s capabilities and its evolving role in scientific and industrial advancements.

Fundamentals of NIR Spectroscopy

Near-Infrared Spectroscopy (NIR) takes advantage of the unique properties of the near-infrared spectrum to offer a versatile, non-invasive means of analyzing molecular composition. In this section we outline the foundational principles of NIR spectroscopy, detailing the physical mechanisms that enable its diverse applications, and highlight the technique’s key characteristics and advantages. We also explore the significance of the NIR spectral range, emphasizing its role in scientific research and industrial process control.

Physical Principles of NIR Spectroscopy

Near-Infrared Spectroscopy (NIR) utilizes the near-infrared region of the electromagnetic spectrum, typically from 800 nm to 2500 nm. The technique is based on the absorption of light as it passes through or reflects off a sample. Molecules within the sample absorb specific wavelengths of NIR light due to overtone and combination vibrations of molecular bonds, primarily C-H, O-H, and N-H groups. This absorption is quantitatively measured to determine the molecular composition and concentration of the sample.

Key Characteristics and Advantages of NIR Spectroscopy

NIR spectroscopy is distinguished by several key characteristics that make it advantageous for a wide range of applications:

- Non-destructive Analysis: Samples require minimal to no preparation, and the integrity is preserved for future tests.

- Versatility: It can analyze solids, liquids, and gases with equal efficacy, making it applicable across various fields.

- Cost-Effectiveness: Compared to other spectroscopic methods, NIR equipment generally involves lower operational and maintenance costs.

- Safety and Convenience: NIR instruments are relatively safe to operate as they do not require high-energy radiation sources.

Overview of NIR Spectral Range and Its Significance

The NIR spectral range is particularly significant due to its ability to probe molecular vibrations without the complexity of mid- or far-infrared regions. This range is less susceptible to water interference, a common issue in more extensive IR analyses, making it ideal for moisture-laden or biological samples. Furthermore, the NIR spectrum is rich in overtones and combination bands, offering a fingerprint by which complex substances can be identified and quantified. This capability is crucial for industries like pharmaceuticals, where precise compositional analysis is necessary for quality control and regulatory compliance.

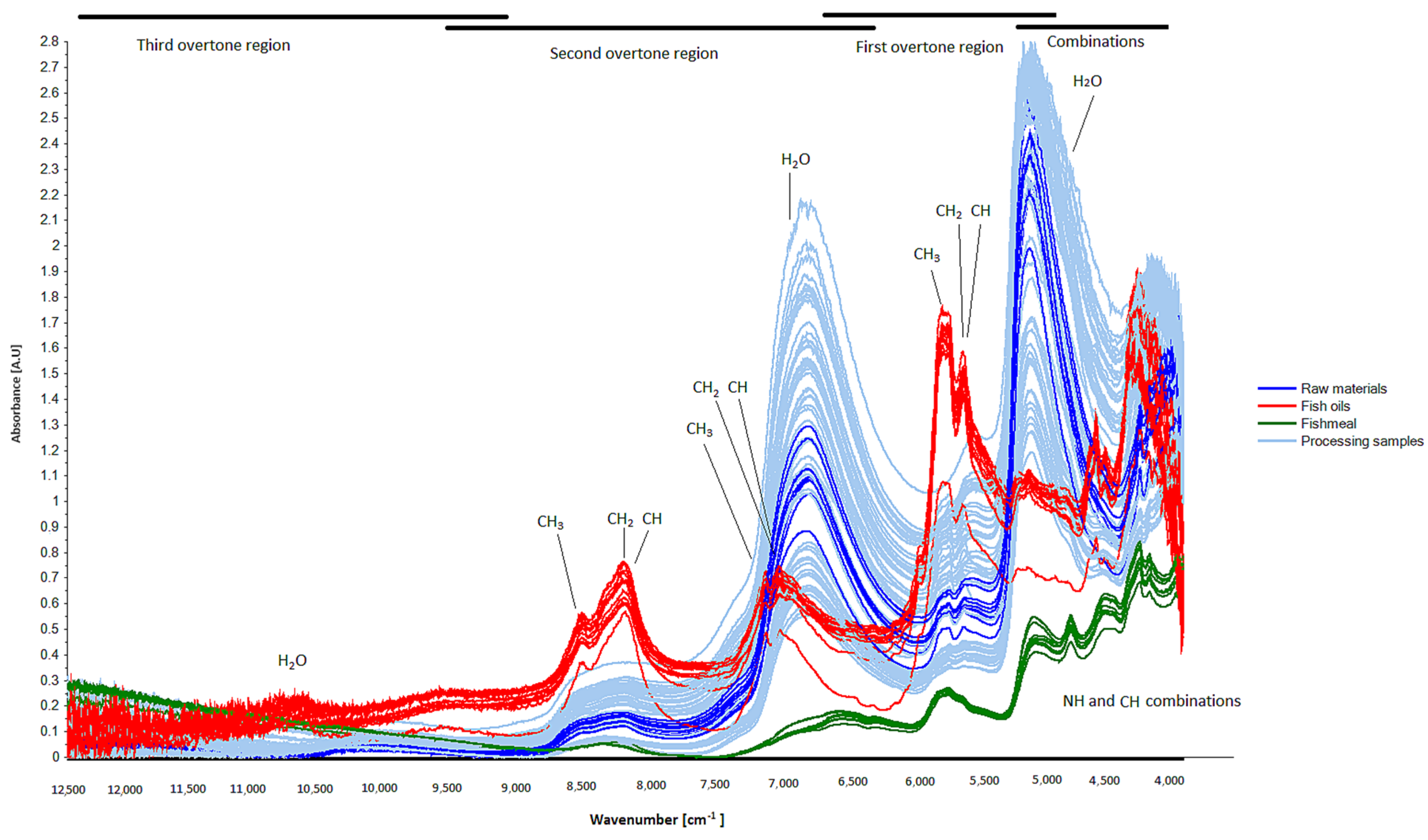

Corrected NIR spectra captured during the processing of fishmeal and oil from pelagic fish species. Key absorption bands from overtones and combination bands of typical chemical bonds found in water, lipids, and proteins are highlighted. Image courtesy of María Gudjónsdóttir, Gudrún Svana Hilmarsdóttir, Ólafur Ögmundarson, and Sigurjón Arason, Faculty of Food Science and Nutrition, University of Iceland, and Matis Food and Biotech R&D. Featured in ‘Near-Infrared Spectroscopy and Chemometrics for Effective Online Quality Monitoring and Process Control during Pelagic Fishmeal and Oil Processing’, Foods 2024, 13(8), 1186. Full citation at the end of this article.

Techniques and Methodologies

Let’s briefly look at the various NIR techniques commonly employed to study various materials:

Reflection Spectroscopy for Solid and Granular Samples

Reflection spectroscopy, particularly in the NIR range, is a primary method for analyzing solid and granular materials due to its rapid, non-destructive nature. In this technique, NIR light is directed towards a sample, and the light reflected back is analyzed. The intensity of the reflected light at different wavelengths provides critical data on the sample’s composition. This method is extensively used in agriculture for analyzing soil and crop health, offering up to 90% accuracy in moisture content determination, critical for assessing crop quality during harvesting. Similarly, in the pharmaceutical industry, reflection spectroscopy facilitates the quick identification of compounds in solid dosage forms, streamlining quality control processes.

Transmission Spectroscopy for Liquids

Transmission spectroscopy involves passing NIR light through a liquid sample and measuring the light intensity after it has traversed the sample. The absorbance at specific wavelengths is directly related to the concentration of chemical components within the sample. This method is invaluable in the food and beverage industry, where it is used to assess the quality of oils, wines, and other transparent liquids. Transmission NIR spectroscopy can achieve a precision level of 0.1% in detecting adulterants in edible oils, enhancing consumer safety and compliance with food standards.

Additional Techniques: Diffuse Reflectance

Diffuse reflectance NIR spectroscopy is particularly useful for samples that are too opaque for transmission methods. It measures the light scattered from a sample rather than absorbed or transmitted, providing detailed information about the sample’s surface and subsurface properties. This technique is crucial in mineralogy for identifying minerals in rocks and sediments where other methods might fail due to the sample’s opacity. Research demonstrated that diffuse reflectance spectroscopy could identify subtle compositional changes in minerals with an accuracy of approximately 95%, critical for geological assessments and mining applications.

Instrumentation and Technology

Fiber optic probes are instrumental in advancing Near-Infrared Spectroscopy (NIR), enabling versatile, in-situ analyses in diverse environments. In this section, we explore the pivotal role of fiber optic probes in NIR spectroscopy, discusses various types optimized for specific applications, and highlights the unique properties of silica fibers that make them ideal for enhancing measurement accuracy and durability in challenging conditions.

Role of Fiber Optic Probes in NIR Spectroscopy

Fiber optic probes are pivotal in extending the capabilities of Near-Infrared (NIR) Spectroscopy beyond traditional laboratory settings. These probes transmit NIR radiation to and from the sample, allowing for measurements in environments that are physically inaccessible, hazardous, or require remote sensing. Their ability to deliver precise and rapid spectroscopic data without significant energy loss is critical for real-time monitoring and control in industrial processes.

Types of Fiber Optic Probes and Their Applications

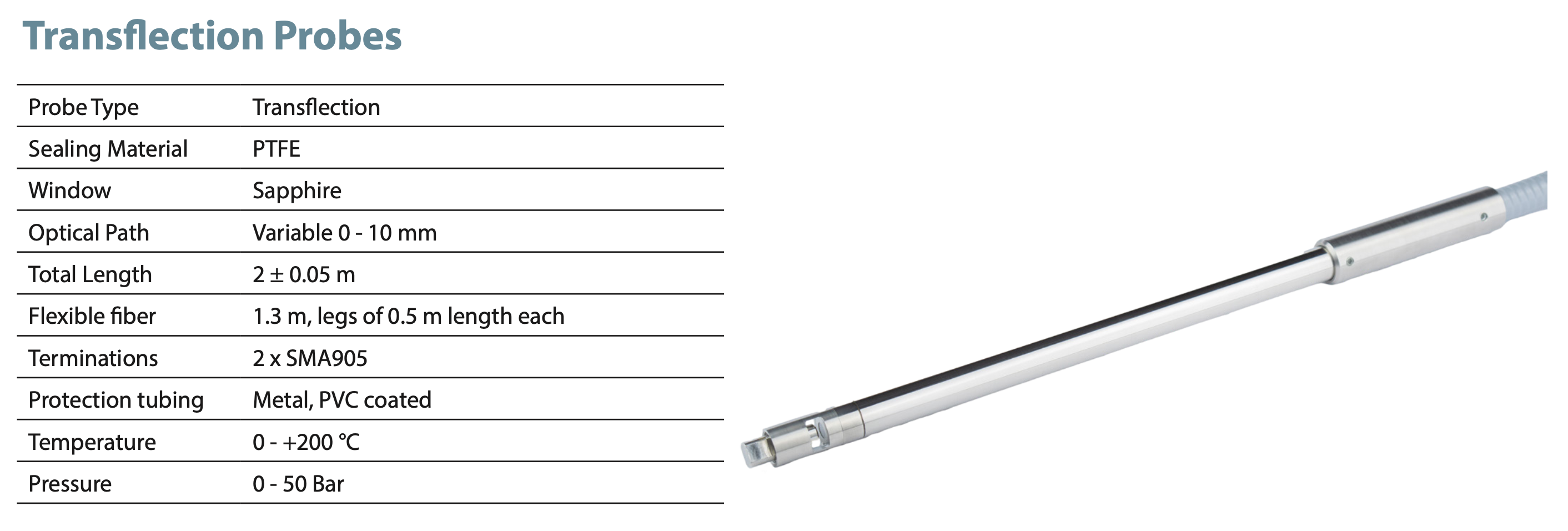

NIR Transflection Probes: These probes are used for Near-Infrared (NIR) spectroscopy, particularly suited for liquid samples. They utilize a variable path length to ensure accurate measurements, making them ideal for analyzing solutions in both laboratory and process environments. Transflection probes are commonly applied in the chemical and petrochemical industries for precise liquid sample analysis.

Transflection Probe featuring a variable optical path (0-10 mm) with sapphire window and PTFE sealing, designed for precise NIR spectroscopy in liquids. The probe is built with durable metal PVC-coated protection tubing, operates at temperatures from 0 to +200°C, and withstands pressures up to 50 bar, making it ideal for industrial and laboratory applications. Image courtesy of art photonics, GmbH

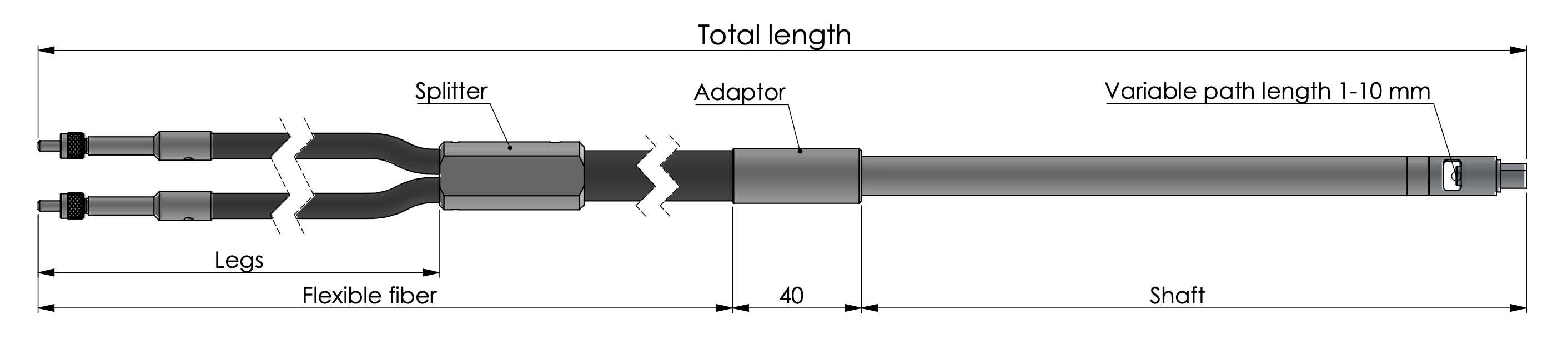

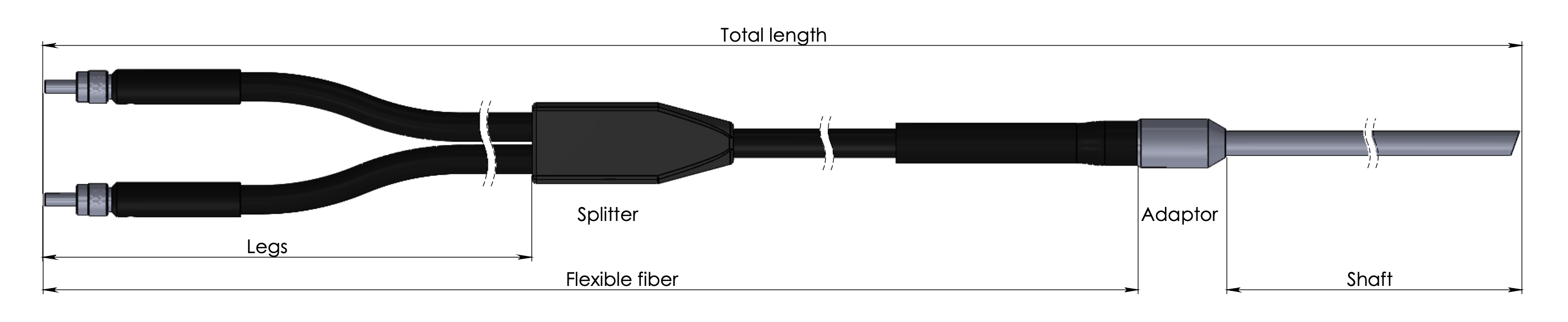

Schematics: Flexible Fiber Shaft with variable path length (1-10 mm) equipped with adaptable legs, featuring a precision-built splitter and adaptor for enhanced NIR spectroscopy performance in diverse applications. This configuration ensures accurate measurements and ease of integration with various spectrometric systems. Image courtesy of art photonics, GmbH

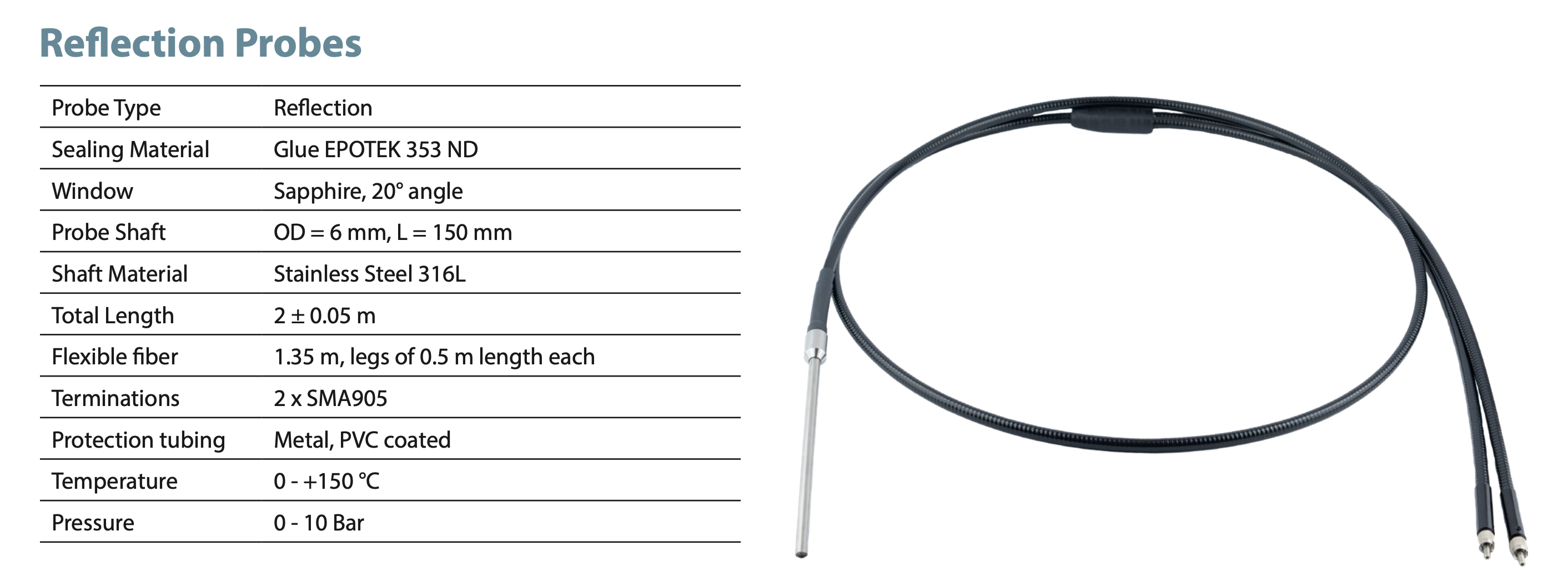

NIR Reflection Probes: Designed for Near-Infrared (NIR) spectroscopy of solids, powders, pastes, and other non-liquid samples, these probes provide reliable reflection measurements. They are widely used in the pharmaceutical, food, and polymer industries to monitor the quality and composition of solid materials.

Reflection Probe with a 6 mm OD stainless steel shaft and sapphire window angled at 20°, designed for precise NIR spectroscopy of solids and surfaces. Featuring EPOTEK 353 ND sealing, a 2-meter total length, and durable metal PVC-coated protection tubing, this probe operates within a temperature range of 0 to +150°C and can withstand pressures up to 10 bar, making it suitable for demanding industrial environments. Image courtesy of art photonics, GmbH

Schematics: Flexible fiber assembly with integrated legs, featuring a splitter and adaptor for versatile connectivity in spectroscopic systems. The design ensures a reliable and efficient transmission of signals across the total length, making it ideal for complex analytical applications. Image courtesy of art photonics, GmbH

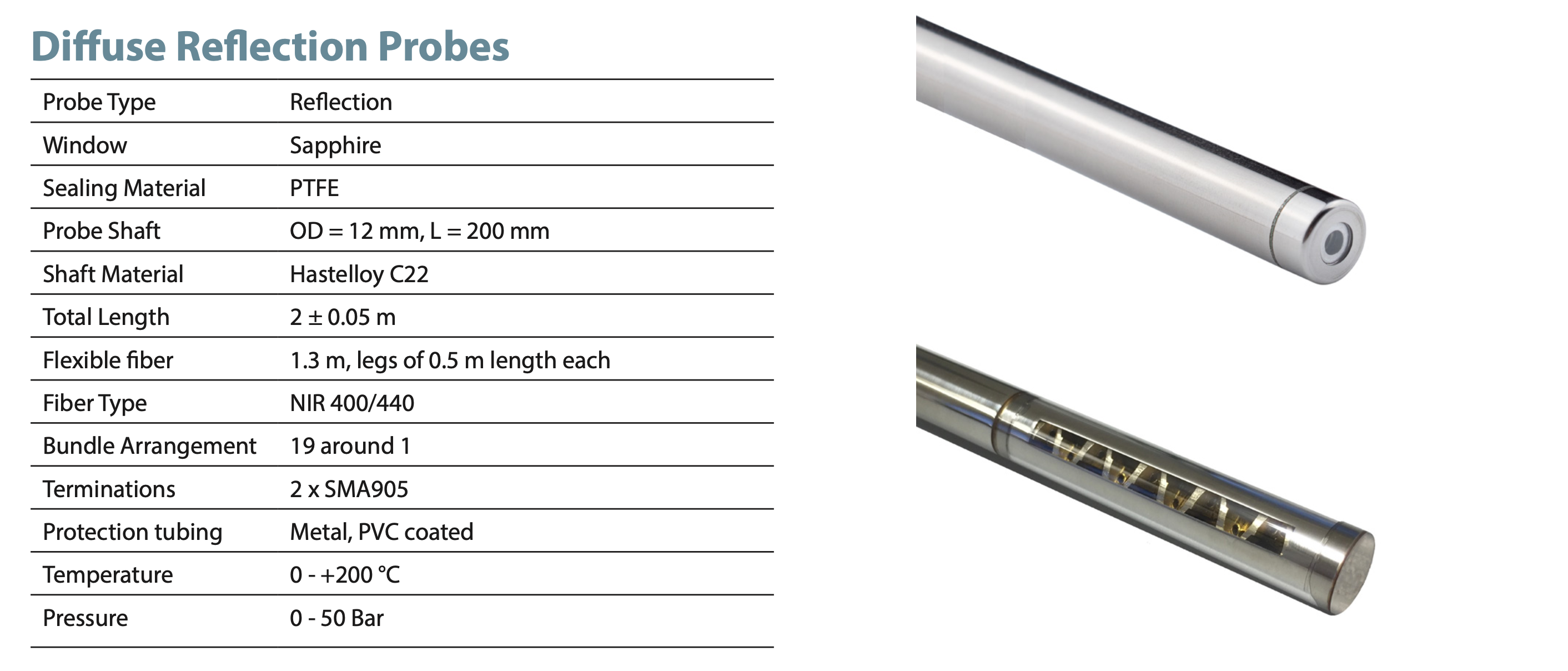

NIR Diffuse Reflection Probes: These probes are tailored for NIR spectroscopy of heterogeneous samples like powders, pastes, and surfaces. They capture diffused reflected light from the sample, making them effective in assessing materials where the surface roughness and particle size are factors. These probes are extensively utilized in the pharmaceutical and food processing industries for quality control.

Diffuse Reflection Probe with a 12 mm OD Hastelloy C22 shaft and sapphire window, designed for NIR spectroscopy of solids and powders. Featuring PTFE sealing, a 2-meter total length, and a robust metal PVC-coated protection tubing, this probe supports a bundle arrangement of 19 around 1 for enhanced signal capture. Operating in a temperature range of 0 to +200°C and withstanding pressures up to 50 bar, it is ideal for demanding industrial environments. Image courtesy of art photonics, GmbH

NIR Transmission Probes: These are specialized for NIR spectroscopy in liquids. By passing light through the sample, they offer precise measurements of chemical composition and concentration. Transmission probes are essential in industries like pharmaceuticals and chemicals, where monitoring the purity and concentration of liquid samples is crucial.

Silica Fibers in NIR Spectroscopy

Silica fibers, used in the construction of fiber optic probes, offer several advantages that enhance NIR spectroscopy:

- Low Optical Losses: Silica fibers facilitate efficient light transmission over long distances with minimal loss, ensuring high-quality spectral data.

- High Flexibility and Durability: The inherent flexibility and durability of silica allow fiber optic probes to be used in a variety of challenging environments. This includes areas with limited space, variable temperatures, and exposure to corrosive substances, thereby expanding the applicability of NIR spectroscopy to fields such as geology, environmental monitoring, and in-process industrial applications.

Applications in Industry and Research

Near-Infrared Spectroscopy (NIR) has revolutionized quality control and safety protocols across multiple industries. By offering non-destructive, rapid analysis capabilities, NIR has become an indispensable tool in fields ranging from pharmaceuticals to food production and beyond. In this section, we examine how NIR spectroscopy is applied in critical industry sectors to enhance product quality, ensure safety, and streamline production processes, highlighting its broad impact on modern industrial practices and scientific research.

Pharmaceutical Monitoring and Quality Control

Near-Infrared Spectroscopy (NIR) plays a critical role in the pharmaceutical industry, streamlining both the development and manufacturing processes. NIR can rapidly identify the chemical composition and confirm the purity of raw materials, intermediates, and finished products without the need for destructive testing. This capability is essential for maintaining stringent quality standards and ensuring compliance with global regulatory requirements. Additionally, NIR facilitates real-time monitoring of drug production processes, enabling immediate adjustments that enhance product consistency and safety.

Food Industry for Quality Assurance and Safety

In the food industry, NIR spectroscopy is a valuable tool for ensuring product quality and safety. It is used to assess the composition and quality of raw materials, monitor production processes, and verify final product specifications without contacting the products. This method can detect contaminants, measure moisture content, and analyze the fat, protein, and carbohydrate levels in various foods efficiently. By providing rapid and accurate results, NIR helps food manufacturers meet health standards, prevent wastage, and optimize production processes.

Additional Applications in Chemical Analysis, Polymer Industry, and More

Beyond pharmaceuticals and food, NIR spectroscopy has a broad range of applications:

- Chemical Analysis: NIR is used to determine the structure and concentration of chemicals in mixtures, facilitating environmental monitoring and compliance with safety regulations.

- Polymer Industry: NIR helps in monitoring chemical properties and compositions during polymer synthesis, crucial for producing materials with specific characteristics and performances.

- Agriculture: It assesses soil health and composition, crop health, and maturity, contributing to precision agriculture practices.

- Textiles: NIR evaluates fiber content and moisture levels, critical for quality control in textile manufacturing.

Process Analytical Technology (PAT) and Remote Monitoring

Process Analytical Technology (PAT) is defined by the FDA as a system for designing, analyzing, and controlling manufacturing through timely measurements of critical quality and performance attributes. This approach is crucial in industries like pharmaceuticals, biotechnology, and food processing, where product quality is directly linked to safety and efficacy. PAT enables manufacturers to ensure quality during the production process rather than through end-product testing, leading to enhanced process efficiency and compliance with regulatory standards.

The use of fiber optic probes in PAT facilitates real-time, in-line monitoring, which is essential for modern manufacturing environments. These probes allow for continuous measurement of critical process parameters, enabling manufacturers to make immediate adjustments to maintain product specifications. The advantages of integrating fiber optic technology in PAT include increased process control, reduced variability, lower risk of non-compliance, and enhanced product consistency.

In general, industries implementing PAT with fiber optic probes have reported improvements in process transparency and control, though specific outcomes can vary based on the application and setting. This technology plays a pivotal role in transforming traditional batch processing into a more efficient, controlled continuous manufacturing environment.

Advancements and Custom Solutions

As Near-Infrared Spectroscopy (NIR) continues to evolve, specialized probes and customized solutions are becoming increasingly vital for addressing the unique challenges of various industries. This section explores the latest advancements in NIR probe technology, detailing the specialized designs and customization options that enhance application-specific performance. We also look ahead to the future trends in NIR technology, anticipating significant developments that promise to transform how NIR spectroscopy is applied in both research and industry settings.

Specialized NIR Probes

The market offers a variety of specialized NIR probes tailored to meet the diverse application needs across industries. These include NIR Transflection Probes, NIR Reflection Probes, and NIR Diffuse Reflection Probes, each designed for specific environmental conditions and challenges.

- NIR Transflection Probes are ideal for analyzing liquid samples, particularly in chemical processing applications, where accurate measurement of solution concentrations is critical.

- NIR Reflection Probes are crucial for monitoring solid materials, powders, and pastes in industries such as pharmaceuticals, food processing, and polymer manufacturing. Their design ensures reliable reflection measurements, even in harsh or variable environments.

- NIR Diffuse Reflection Probes are designed for use with heterogeneous samples, offering precise analysis of surfaces, powders, and other solid forms. These probes are especially useful in quality control processes within the pharmaceutical and food industries, where surface texture and material composition need to be assessed.

These specialized NIR probes are built to withstand demanding conditions, making them indispensable tools in a wide range of industrial applications.

Customization Capabilities for Specific Industrial Needs

The ability to customize NIR probes according to specific industrial requirements is a significant advancement in NIR spectroscopy technology. This customization includes selecting materials, designing optical paths, and modifying probe geometries to suit particular operational contexts. Such adaptability ensures enhanced accuracy and efficiency in NIR applications, allowing for tailored optical interactions with various sample types. This can range from optimizing penetration depth in opaque materials to adjusting the spectral range to focus on specific molecular vibrations.

Future Trends and Potential Developments in NIR Spectroscopy

The future of NIR spectroscopy looks promising with the expected integration of new technologies such as machine learning. These advancements are anticipated to improve the predictive capabilities of NIR instruments, facilitating more complex data analysis and interpretation. Moreover, developments in miniaturization and wireless technology are likely to lead to more compact, portable NIR spectrometers, expanding their usability in decentralized, on-site analysis applications. These trends forecast a broader application of NIR technology in routine quality control and beyond, making it an increasingly essential tool across various fields.

Conclusion

Near-Infrared Spectroscopy (NIR) has established itself as an indispensable tool across various scientific and industrial fields, owing to its versatility, non-invasiveness, and the depth of information it provides. This white paper has explored the fundamental principles of NIR spectroscopy, the essential role of fiber optic probes, and the broad spectrum of applications from pharmaceuticals to food safety. We’ve also highlighted the cutting-edge advancements in probe technology and the customization options that tailor NIR solutions to specific industrial needs.

Looking forward, the integration of NIR spectroscopy with emerging technologies opens a new era of analytical capabilities. These advancements are expected to enhance the precision and efficiency of data analysis, opening up possibilities for more proactive and predictive monitoring systems. The trend towards miniaturization and enhanced portability will likely bring NIR spectroscopy directly into field applications, expanding its use beyond traditional laboratory settings.

As industries continue to emphasize efficiency, safety, and sustainability, the demand for innovative NIR solutions will grow. Remote monitoring technologies, in particular, are set to become more sophisticated, providing real-time insights that are critical for making informed decisions. The future of NIR spectroscopy looks promising, with its potential applications expanding as the technology evolves to meet the needs of a rapidly changing world.

References and Further Reading

- Gudjónsdóttir, M., Hilmarsdóttir, G. S., Ögmundarson, Ó., & Arason, S. (2024). Near-Infrared Spectroscopy and Chemometrics for Effective Online Quality Monitoring and Process Control during Pelagic Fishmeal and Oil Processing. Foods, 13(8), 1186. https://doi.org/10.3390/foods13081186

- Grassi, S., & Alamprese, C. (2018). Advances in NIR spectroscopy applied to process analytical technology in food industries. Current Opinion in Food Science, 22, 17-21.

- Torrent, J., & Barrón, V. (2008). Diffuse Reflectance Spectroscopy. In A. L. Ulery & L. R. Drees (Eds.), Methods of Soil Analysis Part 5—Mineralogical Methods, 5.5 (Chapter 13). SSSA Book Series. https://doi.org/10.2136/sssabookser5.5.c13

- Fang, Q., Hong, H., Zhao, L., Kukolich, S., Yin, K., & Wang, C. (2018). Visible and Near-Infrared Reflectance Spectroscopy for Investigating Soil Mineralogy: A Review. Journal of Spectroscopy, 2018, Article 3168974. https://doi.org/10.1155/2018/3168974