In the vast realm of optical tools, few are as indispensable to professionals as the Neutral Density Filters. Whether it’s an astronomer seeking to reduce the brilliance of celestial bodies or an optics engineer ensuring precision in a laser experiment, the utility of these filters is undeniable. By simply holding one up against the sun, as depicted in our feature image, one can visually appreciate their fundamental purpose: modulating light intensity. But this basic demonstration barely scratches the surface of the intricacies and applications of Neutral Density Filters. This comprehensive guide delves deep into their mechanics, uses, and the pivotal role they play in high-precision scientific and engineering tasks.

Demonstrating the efficacy of a Neutral Density Filter against direct sunlight. Photo Courtesy of PetaPixel

In this article we cover the following topics:

- Scientific Foundations of Neutral Density Filters

- Absorptive vs. Reflective ND Filters

- Types of ND Filters

- Key Considerations in ND Filters for High-Precision Applications

- Applications in Science and Engineering

- Choosing the Right ND Filter for Precision Applications

- Care and Maintenance

- Conclusion

Scientific Foundations of Neutral Density Filters

Neutral Density (ND) Filters operate based on well-established optical principles. Understanding these principles provides insights into their design and functionality.

Light Attenuation and Modulation: The primary function of an ND filter is to attenuate light, which means reducing its intensity. This is achieved by controlling the transmission of photons through the filter medium. Attenuation is quantified in terms of optical density, with higher values indicating greater light reduction.

The effectiveness of an ND filter is closely linked to the absorption properties of its material. As photons traverse the filter, specific wavelengths are absorbed by the filter’s medium, converting their energy, predominantly into heat.

Interaction of Light with Diverse Densities and Materials: The refractive index of a material indicates its ability to bend or slow down light. ND filters utilize materials with particular refractive indices to ensure desired light attenuation. Upon entering a denser medium, light experiences a change in speed, leading to refraction. The degree of refraction is dependent on the difference in refractive indices between the two media. For ND filters, the refractive index, combined with selective absorption characteristics, determines which wavelengths of light are attenuated and by how much.

Additionally, certain materials may cause dispersion, where different light wavelengths propagate at varied velocities within the medium. While dispersion effects are minimized in ND filters, they’re considered in design processes for high-precision applications.

In summary, the operation of Neutral Density Filters revolves around material properties, absorption characteristics, and optical principles. Their precise light control capability is crucial for numerous scientific and engineering applications.

Absorptive vs. Reflective ND Filters

Both absorptive and reflective Neutral Density (ND) filters serve the primary function of reducing light intensity, but they achieve this through distinct mechanisms and material properties.

Absorptive ND Filters

Absorptive ND filters attenuate light through the principle of absorption. By capturing and dissipating specific wavelengths of light, these filters offer control over the light’s intensity that passes through. The following aspects define their operation and characteristics:

- Mechanism: They function by absorbing a portion of the incoming light, with the degree of absorption influenced by the filter’s material composition and thickness.

- Materials: Predominantly made of dyed glass or polymer substrates, the material chosen dictates the filter’s specific absorption spectrum. As an example, some glasses are specialized to absorb ultraviolet (UV) or infrared (IR) light, while others target the visible light spectrum.

- Advantages: Absorptive ND filters are known for providing consistent attenuation across the filter surface, functioning effectively across a broad bandwidth, and inducing minimal light scattering.

- Drawbacks: A primary concern is the conversion of absorbed light to heat, potentially causing localized temperature increases which can be problematic in precision applications. Additionally, their performance is constrained by the intrinsic absorption properties of the materials used.

Reflective ND Filters:

Reflective ND filters attenuate light intensity by harnessing the principle of reflection. Instead of absorbing light, these filters redirect a portion of it away from the intended path, providing another means to control the light’s intensity. The following elements characterize their design and functionality:

- Mechanism: The primary operation involves reflecting a portion of the incoming light away, using specially designed surfaces or coatings.

- Materials and Coatings: Commonly constructed from dielectric-coated glass or metal-coated polymers, the effectiveness of reflection is often enhanced by multi-layered coatings. These coatings consist of materials with varying refractive indices, designed to optimize specific reflection properties.

- Advantages: Reflective ND filters are capable of handling high-power light sources without significant heating due to their non-absorptive nature. Additionally, the flexibility of multi-layer coatings offers tailored reflection spectra for precise control over specific wavelength ranges.

- Drawbacks: One challenge with these filters is potential issues with unwanted optical phenomena, like ghosting or flare, due to multiple reflections. Additionally, achieving consistent reflection across a broad bandwidth can be more complex compared to absorptive filters.

Types of ND Filters

ND filters come in various types, each serving unique applications based on their design and functionality:

Fixed ND Filters: These filters have a set density level, meaning they reduce light intensity by a consistent amount across their surface. Engineers and scientists use them in applications that require a consistent light attenuation, such as baseline calibration tests or when working with a known light source intensity.

Variable ND Filters: Operating on the principle of two polarizing layers, variable ND filters allow users to adjust light intensity continuously. By rotating one layer relative to the other, they control the amount of light that passes through. High-precision applications for variable ND filters include finely-tuned light modulation in optical experiments or adaptive light control in advanced imaging systems.

Variable ND Filter: A tool for precision light control. Photo Courtesy of JnR Photography.

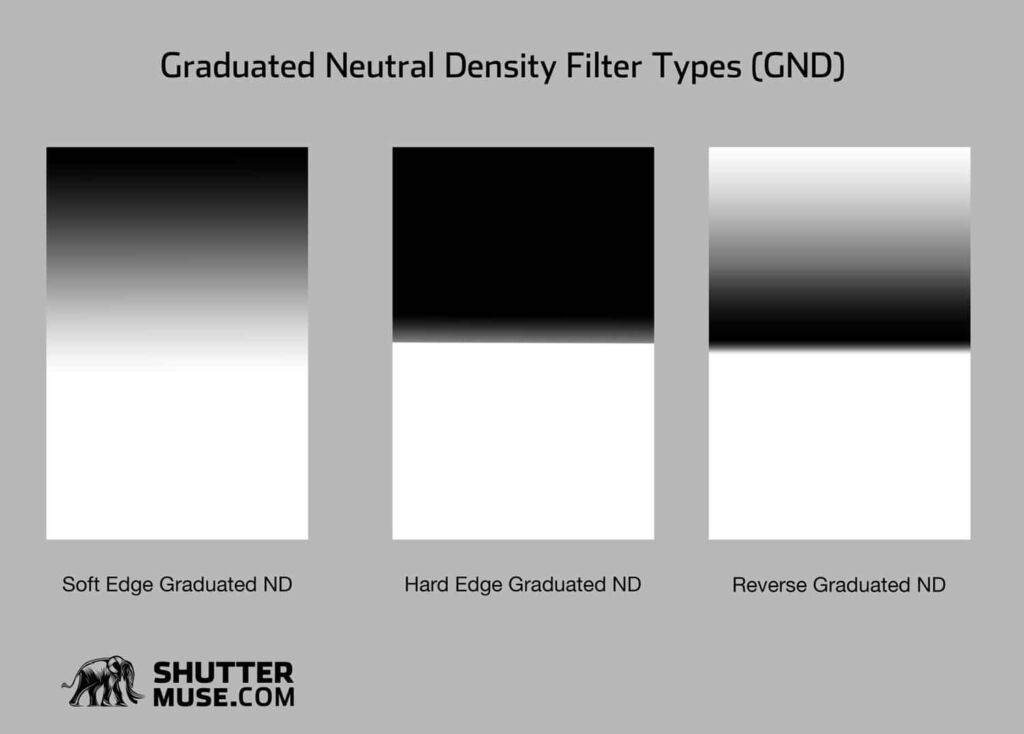

Graduated ND Filters: These filters present a gradient in their density, transitioning from clear to a specific density level. This design enables the control of light intensity across a surface unevenly. Such filters prove crucial in experiments or applications where a gradient of light intensity is needed, like testing the response of materials to varying light intensities or in specific imaging setups that require a differential light profile.

Varieties of Graduated ND Filters: From Soft to Reverse Edges. Photo Courtesy of ShutterMuse.

Key Considerations in ND Filters for High-Precision Applications

In high-precision applications, the choice of ND filters can significantly influence the outcome of an experiment or the quality of an optical setup. Professionals must weigh several crucial factors when selecting or designing the appropriate ND filter:

Material & Build Quality: The material type determines the filter’s absorption and reflection properties. High-quality materials ensure consistent and predictable light attenuation. Additionally, coatings applied to ND filters can enhance their performance, reduce unwanted reflections, or cater to specific wavelength requirements. When targeting precision, one shouldn’t compromise on the material’s quality or the integrity of the coatings.

Transmission Curves: Every ND filter possesses a transmission curve, representing how it attenuates light across different wavelengths. For high-precision tasks, it’s vital to understand the spectral transmission characteristics of the filter in use. The curve should align with the application’s requirements, ensuring optimal light control across the necessary spectrum.

Optical Clarity & Flatness: A top-tier ND filter should introduce minimal distortion to the transmitted light. Optical clarity ensures the light maintains its original characteristics, while flatness ensures uniformity across the filter’s surface. Deviations in clarity or flatness can lead to aberrations, reducing the accuracy of optical setups or measurements.

Tolerances: In high-precision applications, even minor manufacturing deviations can have pronounced effects. Tight manufacturing tolerances guarantee that the ND filter’s specifications align closely with its actual performance. For professionals operating in fields like aerospace, defense, or advanced research, adhering to strict tolerances isn’t just a recommendation—it’s a necessity.

By addressing these considerations, professionals can ensure that their choice of ND filter aligns perfectly with their high-precision requirements, eliminating potential inconsistencies or inaccuracies in their work.

Applications in Science and Engineering

ND filters, given their unique ability to modulate light, play an integral role in numerous high-precision applications across various fields in science and engineering. Their influence extends from terrestrial laboratories to the vast expanse of space:

Laboratory Research: In many scientific experiments, especially those involving sensitive materials or biological specimens, there’s a need for controlled light exposure. ND filters offer researchers the ability to simulate various lighting conditions, ensuring that experimental parameters are maintained with precision. For instance, in studies exploring the effects of light on photosensitive chemicals or the behavior of organisms under varying light intensities, ND filters become indispensable tools.

Laser Applications: Lasers, with their high-intensity beams, require modulation in many contexts, be it for safety, equipment compatibility, or the requirements of a particular procedure. ND filters can adjust laser intensities without altering the inherent characteristics of the beam, such as its coherence or phase. This capability is critical in applications like medical laser treatments, where precise intensity control can mean the difference between success and harm.

Telescope & Astronomy: The cosmos, with its myriad of light-emitting bodies, presents challenges in capturing clear images without overexposure. ND filters, especially those of the variable and graduated types, help astronomers manage intense light sources like stars or planets, ensuring that celestial observations and recordings retain detail without saturation.

Optical Engineering: As the field dedicated to designing and testing optical devices, optical engineering often involves calibrating devices under specific light conditions or intensities. ND filters allow engineers to adjust the light reaching a device during testing, ensuring accurate calibration and validation. Whether it’s in the development of camera sensors, microscopes, or advanced imaging systems, ND filters support the rigorous standards of optical engineering.

Choosing the Right ND Filter for Precision Applications

In high-precision optical applications, the selection of the correct ND filter is more than just a choice—it’s a pivotal decision that can influence the accuracy and reliability of results. To make an informed decision, professionals must navigate various factors and considerations:

Absorptive vs. Reflective: The primary decision rests on whether to opt for an absorptive ND filter, which attenuates light by absorbing it, or a reflective one, which redirects light away. The choice often depends on the specific application needs, such as the requirement for broad bandwidth operation or the need to handle high-power light sources.

Optical Density Range: Depending on the application, there might be a need for slight attenuation or a significant reduction in light intensity. Understanding the optical density range that the filter offers ensures it meets the demands of the task at hand.

Wavelength Range: Not all ND filters work effectively across all wavelengths. Depending on the light source or the specific optical setup, it’s essential to select a filter that provides consistent performance over the desired wavelength range.

Size: ND filters come in various sizes, catering to different optical setups. Whether it’s for a large telescope or a compact laboratory instrument, the filter’s size should align with the intended equipment.

The Significance of Product Certifications and Standards: In precision applications, consistency is paramount. Choosing ND filters with recognized certifications ensures they’ve met rigorous industry standards. In sectors like aerospace, medicine, or defense, such standards are vital for reliable outcomes.

By weighing these considerations and recognizing the importance of industry certifications, professionals can make a confident choice, ensuring their ND filter meets the high standards of precision applications.

Care and Maintenance

Neutral Density filters, especially those used in high-precision applications, demand meticulous care and maintenance. Ensuring their longevity and consistent performance is a matter of adopting proper cleaning techniques and storage practices:

Cleaning Methods to Ensure Optical Clarity:

Dust Removal: Before any wet cleaning, it’s vital to remove any dust or loose particles from the filter’s surface. Use a soft-bristled brush or a blower bulb to gently remove debris. Avoid using compressed air, as the force may embed particles into the filter or cause scratches.

Spot Cleaning: For smudges, fingerprints, or localized spots, a lens pen or a microfiber cloth moistened with a drop of lens cleaning solution can be effective. Gently wipe in a circular motion, moving from the center of the filter outwards.

Deep Cleaning: For more stubborn residues or when the entire filter needs cleaning, use a lens cleaning solution applied to a microfiber cloth or lens tissue. Again, clean in a gentle, circular motion. Ensure the filter is completely dry before storing or using it.

Avoiding Common Mistakes: Never use abrasive materials or household cleaners. Always avoid touching the filter surface with fingers, as oils and acids can degrade coatings over time.

Storage Solutions to Prolong the Lifespan of Filters:

Protective Cases: Always store ND filters in protective cases or pouches when not in use. These cases shield the filters from dust, moisture, and potential physical damage.

Humidity Control: In environments prone to high humidity, consider using desiccant packets within the filter storage cases. This helps prevent the formation of mold or fungus on the filter surfaces.

Temperature Regulation: Store filters in a stable temperature environment. Avoid leaving them in places where they might experience rapid temperature fluctuations, such as near heaters or in direct sunlight. These conditions can adversely affect the filter coatings or materials.

Regular care and proper storage practices not only enhance the performance of ND filters but also significantly extend their functional lifespan, ensuring they remain valuable assets in precision applications.

Conclusion

Neutral Density filters play a vital role in the realm of optics. These tools are widely used, spanning applications from intricate lab research to vast astronomical observations. A deep understanding of their operational science is fundamental, guiding professionals to harness their full potential. Notably, there are key differences between absorptive and reflective filters, with each serving specific needs. Just as crucial as understanding these filters is the commitment to their care and maintenance. This will ensure their durability and consistent performance. In today’s technologically advanced world, where precision and light manipulation are paramount, ND filters emerge as indispensable tools, shaping the future of optical advancements.