Consider MEMS (Micro Electro-Mechanical Systems) and working with objects in the nanometer scale. In this context extreme precision is needed. Can you describe how we move things at such a small scale? In your thoughts you may come to see some issues that can arise. One issue is the need for high accuracy and high repeatability when making micro-adjustments. To address these issues in the real world many industries have decided to integrating piezoelectric actuators.

What are piezoelectric actuators?

Like all actuators, piezoelectric actuators are components which allow control over a mechanism in a mechanical system. This control allows users to make joints hold angles, apply forces, measure positions, and detect changes among other things.

Piezoelectric actuators (aka piezo actuators) are designed to have architecture which integrates the properties of piezoelectric materials in order to actuate. These are materials that can produce electrical energy when under mechanical stress, an effect known as the piezoelectric effect. This is a reversible relationship so the addition of electrical energy will produce strain in the piezoelectric material. The reversing of this stress/electrical relationship is called the converse piezoelectric effect. In practice this means electrical signals can determine the shape of a piezoelectric material based on its configuration. Below is an illustration of the piezoelectric effect (a) and the converse piezoelectric effect (b).

The piezoelectric effect and it’s converse. Image courtesy of wellpcb.com

These materials have been used to create a plethora of piezo actuators which use electric signals to directly and precisely actuate. The two main kinds are stack and stripe piezoelectric actuators.

In addition to this, because stress in a piezoelectric material results in a voltage, sensors are also made using piezoelectric materials known as piezo sensors.

Applications of piezoelectric actuators

While the introduction of this article posed the novelty of piezoelectric actuators for MEMS, its applications are extremely varied. From consumer products such as lighters and buzzers to medical tools, aerospace sensors, even industrial fine tuning; piezo actuators have incredible uses.

Aerospace piezoelectric actuators

Piezoelectric actuators in the aerospace industry provide the following uses:

Micro-thrusters in satellites: Due to the high accuracy of piezo actuators, they have found use in providing precise movement of micro thrusters in satellites.

Active vibration damping: Piezo actuators placed appropriately in a build can actively dampen noise. Noise/vibration reduction can reduce the energy consumption of the craft.

Structural health monitoring: The use of piezoelectric actuators allows for continuous monitoring of a structure’s integrity. In transport, infrastructure, and building structures which require high levels of safety, continuous monitoring of structural health becomes highly relevant.

Medical piezoelectric actuators

The precise nature of piezoelectric actuators lends itself well to the accuracy needs of the medical industry.

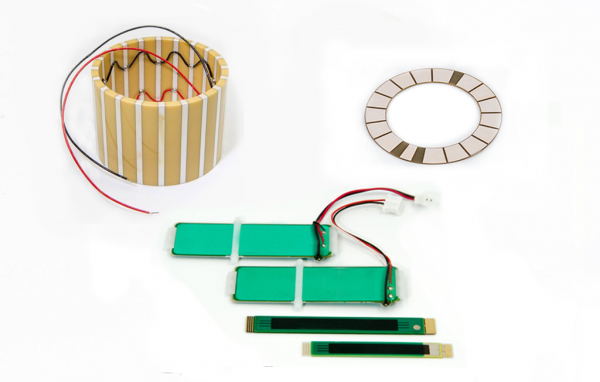

Piezoelectric components such as ring, tube, and bending actuators have various uses in medical applications. Image courtesy of piezodirect.com

Nanopositioning: The extremely precise nature of piezo actuators makes positioning medical devices much more accurate. This increase in accuracy allows medical practicianers to more effectively perform treatments which require high accuracy such as surgery that uses electro-mechanical devices that cut, position, and adjust parts within the body.

Laser position control: In laser eye surgery a piezo actuator controls the position of the laser used to perform the operation. Below is shown an image of a laser eye surgery which uses piezo actuators to precisely position then move the laser pointed at one’s eye. Accuracy in this situation is important because these procedures require the following of extremely exact paths.

Piezoelectric actuators can be responsible for the precise control of a laser’s position and refraction. Image courtesy of piezodiect.com

Industrial piezoelectric actuators:

In the industrial sector piezoelectric actuators play an important role for nanopositioning and precision automation. This is due to their reliably precise nature which is accurate in the sub-nanometer scale. Another benefit to piezo actuators is the quick response time of the effect.

Nanopositioning: Due again to the precise nature of piezo actuation these actuators have found great use in positioning accurately. In an industrial context this includes precise placement of tool and end effector parts.

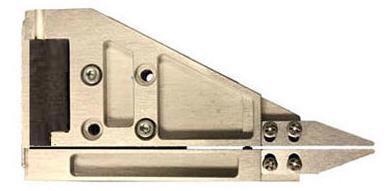

Piezoelectric gripper: This application involves use of a piezoelectric actuator to create a gripper capable of high force, quick response time, and nanometer precision.

Consumer goods and home electronics:

Piezoelectric actuators have innovatively found uses in everyday products. Such products include igniters, buzzers, security/alarm systems, humidifiers, and even electric toothbrushes. In addition to actuation allowing for creation of these products, they also open the door for miniaturizing these products with mini piezo sensors.

Nano-systems and piezoelectric actuators:

As mentioned at the beginning of this article, small scale systems benefit tremendously from having the accurate and precise actuation of piezoelectric actuators. When it comes to nanometer scale systems, component manufacturing and assembly come with challenges which have been overcome with the use of piezo actuators.

Micro-machining: Similar to how piezoelectric actuators are used in larger scale industrial machining, micromachining requires high precision. Given that piezo actuators have precision down to the sub-nanometer scale and have high reliability, their use in the micromachining process makes them invaluable for producing high tolerance small scale parts. This value is because of the nanopositioning possible with these actuators and the need for nanopositioning in micro-machining.

Micro-assembly: Regardless of end effector/tool, assembly of components in the nanometer/micrometer scale comes with various challenges when it comes to placement and joining. One way piezoelectric actuators assist in confronting these challenges is through the precision and repeatability of their actuation. Micro assembly uses various methods which would be impossible without accurate position in the nanoscale. These methods include “pick & place” and guided transfer.

![The steps of microassembly for complex MOEMS presented in [13].](https://www.researchgate.net/profile/Tamadazte-Brahim/publication/310810573/figure/fig1/AS:445873105707008@1483315840525/The-steps-of-microassembly-for-complex-MOEMS-presented-in-13.png)

Example of micro-assembly, placing holder on base plate using microgripper. Image courtesy of researchgate.com

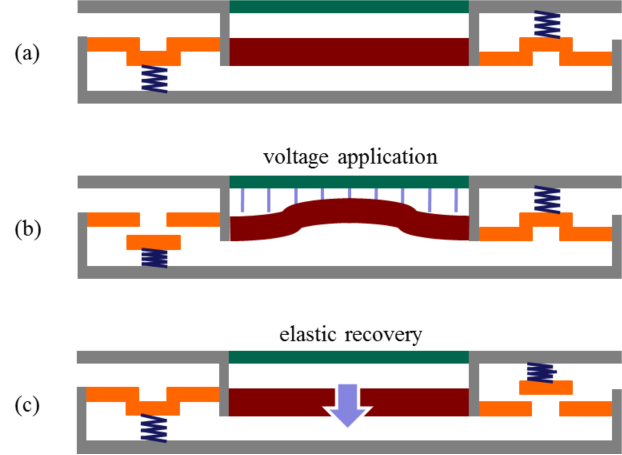

Micro-pumping: Our final section on piezo actuators for micro/nanosystems will be on the innovative nature of piezo micropumps. Micropumps are simply pumps which function to move very small quantities of fluids at a time. The various constructions of micropumps include many varieties which involve the expansion and constriction of a space, a situation which lends itself to synergy with the shape changing nature of piezo actuators.

(a) Rest state. (b) Application of voltage on piezoelectric disk which changes its shape and pulls fluid in from the inlet valve. (c) Recovery phase for the disk which pushes fluid out of the inner chamber. Image courtesy of mems.polimi.it

Conclusion

The spread and use of piezoelectric actuators has led to a variety of uses in many different industries. These uses show the innovation and creativity research and development has when it comes to using the tools we are familiar with. When it comes to the small scale, the current best actuator type is those powered by the piezoelectric effect and its converse. Both micro and macro scale systems can benefit from the use of these mechanical electrical curiosities.

This article is brought to you by Connet Laser Technology Co., Ltd. Connet Laser designs and manufactures fiber laser solutions for a broad range of scientific and industrial application.