Fibers lasers are a very commonly used type of laser. Whether they are being used for communication purposes, materials processing, or medicine, they have come a long way from their humble beginning. This article covers the invention, development, and ultimately, the rise of fiber lasers.

High-Power Polarization Maintaining EDFA for C-band. As seen on FindLight

Today’s blog post is sponsored by RPMC Lasers – a leading supplier of lasers in North America.

Invention of the Fiber Laser

The inventor of the fiber laser was Elias Snitzer. When he started at American Optics (AO), despite the company’s desire to officially establish themselves as a prominent force in fiber optics through more publications, Snitzer was not initially working towards creating a fiber-based laser. He was hired to work on projects dealing with exploring waveguide-mode propagation. Snitzer built a setup at AO to create his own fibers for his wave-guide mode studies. Creating thin enough fibers, he realized, made them act as single-mode waveguides. Snitzer thought that these supported waveguide modes in the glass fiber could make a good host for a maser, since the waveguide structure already existed.

At that time, most colleagues Snitzer encountered maintained the stance that lasing could not (and would not) occur using glass. Undeterred, Snitzer and his group at AO pressed on using different types of doped glasses. Through their attempts, they realized that by cladding the fiber and having a good interface between the core and cladding made the quality of the end reflectors less critical to the fiber’s success.

One of the other keys to creating the fiber laser was using the right material to dope the glass. They realized that visible fluoresces were not going to work, so they moved into the infrared. In collecting the data, he realized neodymium gave very high signals when fluorescing. From that, the research continued using different compositions of glasses doped with rare earth elements. In 1961, they were finally able to observe lasing using the neodymium glass rods. The work was published in Physical Review Letters in 1961.

Fiber Laser Progression

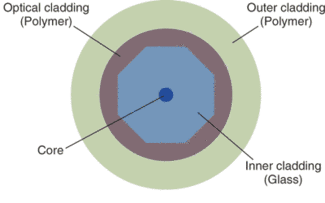

While the fiber laser was invented in 1961, it took a good twenty years before it was developed and integrated into the commercial market. Snitzer had a hand here as well, with the invention of the double-clad fiber laser in 1988. Double-clad fiber lasers facilitate a higher power output. In double-clad fibers, the laser light propagates through the core, but the pump light travels through the inner cladding that surrounds the core. The inner core is then encased in an outer cladding. The refractive index of the inner cladding is lower than that of the core but higher than that of the outer cladding.

Double-clad fiber lasers are still used today. There are double-clad fiber lasers available with different geometries for the inner core. The different geometries make it easier to match properties of the pump source to the fiber for improved coupling. Snitzer contributed a substantial amount to the field of fiber optics, which, among other things and the lasers mentioned, also included inventing fiber amplifier.

A cross-sectional diagram of a typical dual-clad fiber laser structure. Courtesy of Laser Focus World.

In 1990, work by IPG Photonics in Moscow improved ytterbium-doped fiber lasers to output power of 1 W. By 2009, they recorded a single-mode fiber output of 10-kW. IPG has continued to innovate fiber lasers since that then. As fiber grew more popular and for telecommunications industry was on the rise, unsurprisingly, fiber laser research grew too, though keeping a lower profile than fiber communications.

Fiber Lasers Today

Fiber lasers today are available in multiple configurations. They can be continuous wave (CW), Q-switched, narrow linewidth, mode-locked, gain-switched, and quasi-continuous wave (QCW) to list a few. Most single-mode fiber lasers tend to be CW. QCW lasers are one of the newer types of fiber lasers. When compared to CW lasers, QCW lasers have both a higher peak power and lower average power. QCW lasers come in both the single-mode and multi-mode variety.

Most fiber lasers have erbium, neodymium, and ytterbium as their gain medium and are diode-pumped. There are different methods to pumping fiber lasers. One method of pumping is side pumping. In side pumping, the pump light is directed into the fiber from an angle close to perpendicular to the laser. Side pumping also distributes absorbed pump power smoothly. This method makes it possible to use pump sources with low spatial coherence allowing to combine different light sources to use as a pump. The other commonly used method of pumping is end pumping. End pumping usually results in a better-quality beam and higher gain than side pumping. A downside of end pumping is that unwanted higher order resonant modes can be present. While double-clad fiber lasers are usually end pumped, they can be side pumped.

Advantages of Fiber Lasers

Fiber lasers have some advantages over other laser types, dependent upon their intended use. One of the benefits of fiber lasers is their sensitivity. Since they are meant to be coupled into fiber, it is difficult to move them out of alignment, unlike other lasers. They are typically more compact than your general laser. Comparatively, fiber lasers also have a lower heat output and lower power consumption with better beam quality than their non-fiber counterparts.

Conclusion

Fiber lasers have gone from milliwatt output powers at the time of their invention to now being capable of outputting power on the order of kilowatts. For instance, the US Navy was in the process of developing a of a 30-kW laser and intends to build a weapon system housing a 150-kW fiber laser. Through the years, it is clear that innovation has improved fiber laser versatility and has rendered them invaluable to a range of industries.

Do you know any interesting or odd facts about fiber lasers? Please comment below.

If you liked this article you might also like our comprehensive guide on gas lasers.