Attempts at solar-pumped lasers have been reported since 1963. This is unsurprising, as it mirrors the timeline for when the modern environmental movement was gaining traction worldwide, but especially in the United States. As the push for sustainable solutions continues to grow and remain a prominent point of focus in all fields, creating a “greener” laser that employs a renewable resource as a pumping mechanism while retaining comparable efficiency is one of the next frontiers in laser development. A group out of Tokai University in Tokyo, Japan has created a proof-of-concept Solar-Pumped Laser (SPL) design that has achieved just that. A summary of their work as reported to Communications Physics is included below with additional details taken from Tokai University’s press release.

Attempts for Solar-Pumped Lasers

Since pumping is typically done through electrical or chemical means, previous attempts at solar-pumped lasers have posed certain challenges regarding how best to collect the random light from the sun and turn it into a coherent, monochromatic beam. All solar-pumped laser designs to date have included either a large focusing lens and/or a very precise solar tracking system—both of which can prove to be large and expensive. These designs also require direct sunlight for pumping to occur at a rate where the gain equals or exceeds the threshold, thus making laser usage on cloudy days next to impossible.

The Tokai University group had previously improved upon this old standard with a solar-pumped laser design that utilized a Neodymium doped fiber coupled with cascade energy transfer. A toroidal lens was used to concentrate the sunlight to a ring of the same diameter as the fiver. Toroidal lenses have a wide variety of usages, ranging from eyeglasses and contact lenses (to help correct astigmatism) to laser applications. The required solar concentration for this laser’s pumping threshold was low at 1.5 W cm-2 (15 suns) meaning direct sunlight was no longer necessary. However, this design still required a lens and solar tracking system that ideally would be eliminated.

Their most recent design has provided the breakthrough they have sought after—a SPL where a focusing lens and tracking system are no longer needed. Instead, this SPL is completely planar and a few millimeters thick, reminiscent of photovoltaic cells/solar panels. This flat panel is made possible by using a luminescent solar collector (LSC) “combined with a fiber laser with transverse excitation geometry under natural sunlight”. This format makes them conducive to being used on the roofs of vehicles or installed in remote areas with limited electricity access. These are just two of the applications that the team envisions for the SPL.

Solar-Pumped Laser Design

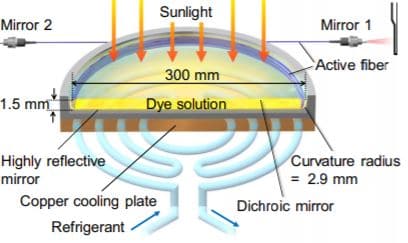

The SPL is structured in layers. The top layer is a dichroic mirror followed by the coiled fiber immersed in a sensitizer dye solution. The chamber in which the sensitizer is contained is what was referred to earlier as the luminescent solar collector. Then there is a reflective mirror, and beneath that is a copper cooling pate with refrigerant running under it. During operation and testing, the copper plate cooled the LSC to -25o C to minimize thermal losses.

Cross-sectional diagram of the solar-pumped laser construction. Courtesy of Tokai University

The sensitizer solution is a key component for the SPL operation. The solution strongly absorbs in the 450nm to 550nm range and re-emits the absorbed photons at a specific frequency. The re-emitted photons will then become trapped inside between the dichroic and reflective mirrors and will eventually collide with and excite the fiber. This excitation causes oscillations that drive the pumping. This excitation driven by the sensitizer solution multiplies the gain by a factor of 30 or greater, making it more than sufficient for solar-powered lasing. The lasing begins to occur at a sunlight intensity of 0.06 W cm-2.

After pumping reaches the lasing threshold, the SPL’s output-power is linearly related to the length of the fiber. This makes it comparatively low cost to increase the power-output by simply using a longer fiber as opposed to the designs that would require a larger lens or mirror.

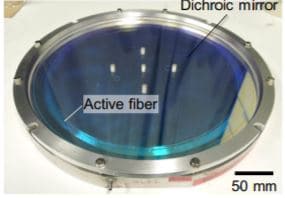

Photo of the complete solar-pumped laser. Courtesy of Tokai University

Testing and Results

Some of the tests that were performed included assessing the power output of the SPL as a function of the output couplers when exposed to 1 sun (100 mW cm-2). The group used a Monte Carlo simulation to determine the efficiency of the system. This simulation set the sidewall reflection to the same value as was experimentally determined, 45% reflectance, to improve the simulation’s accuracy. They assessed the system and determined the sidewall was the component currently introducing the most loss in the system due its reflection loss. They calculated that if the fiber length and reflectance were increased, the solar-to-laser efficiency would also increase.

Other calculations revealed that if the sensitizer solution peak emission wavelength is changed from visible to the near IR, the efficiency could increase by a factor of seven. Such a sensitizer solution exists in the form of formamide lead iodide perovskite quantum dot, and the group is now exploring experimental results using this material.

From these findings and others, it is theorized that the SPL could reach an 8% efficiency upon further development. Despite this efficiency being less than half that of photovoltaic panels and about a quarter to a third of that for laser diode pumped fiber lasers, the prospects for SPL look bright. This is primarily due to the substantial cost benefit of not having a solar tracker or large lens, as well as using a renewable pumping source.

Conclusion

Not only has Tokai University made solar-pumped lasers a reality, they have made their usage realistic by providing better versatility at a lower cost than previous attempts.

This post was sponsored by RPMC Lasers, Inc. - US leader in laser solutions for various applications