Since the first demonstration of the laser in 1960, people have endeavored to make lasers more compact. Semiconductor lasers achieved this desired compactness employing so called heterostructures. This helped operate lasers at smaller sizes and currents. However, problems such as poor beam quality and yield still limited the applications and made mass manufacturing difficult. The situation has changed with the invention of the surface emitting lasers in 1979. This opened up applications for using compact lasers in optical communication links, in which they are ubiquitous today.

Surface emitting lasers offered better beam quality and testing methods compared to other semiconductor lasers. This is made possible with better fabrication techniques such as Molecular Beam Epitaxy, which gives better control of layer roughness. Today these lasers not only find uses in optical communication links, but also in 3D sensing applications, gesture recognition, and more. Most of these lasers operate in the infrared region, with a few operating closer to red. Currently, worldwide research is focused on getting them to emit in the blue and UV regions.

In this article, we discuss the structure of surface emitting lasers, and their key advantages compared to other semiconductor lasers. We also touch upon some of the applications for using them with fiber optics and 3D sensing.

Surface Emitting Structure

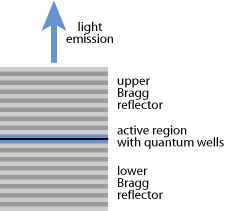

Diodes can be classified based on their emission characteristics: edge-emitting, or surface emitting. Consider a laser diode structure in which layers are stacked vertically. In such a structure, edge-emitting lasers emit beams horizontally and are guided by the layers at the top and bottom. In contrast, surface emitting lasers emit light vertically. Here the top and bottom layers serve as mirrors. Vertical cavity surface emitting laser (VCSEL) is a type of surface emitting laser. The top and bottom mirrors are designed as distributed Bragg reflectors (DBR). The main active region is filled with single or multiple quantum wells. Light is reflected between the top and bottom mirrors with the active region amplifying the light at each pass. The active region is electrically pumped, so metal contacts at the top and bottom supply the electrons and holes necessary for amplifying the photons. Below is a schematic diagram of the structure of such a device.

Structure of a VCSEL. Courtesy rp-photonics

VCSELs have found many applications as they are easy to manufacture and test in bulk. This is because while depositing layers vertically, one can easily test vertical beam output rather than horizontal beams. At the same time, one can place many of them adjacently to get high yields. One area where they are useful is for communication in fiber optic cables. InP VCSELs manufactured for 1550 nm wavelength can be modulated to send information in optical fibers.

Properties

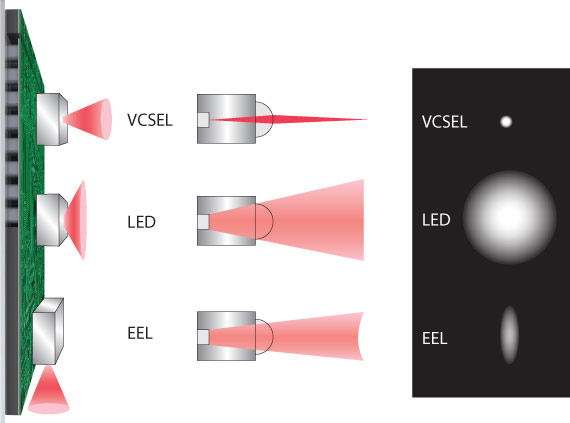

Beam quality and yield are the main properties that make using VCSELs more useful. In edge emitting lasers, the coherent beam is more elliptical rather than circular. Moreover, the spot size is smaller as shown in the image below.

Beam quality of a) surface emitting, b) LEDs, and c) Edge emitting lasers. VCSELs have a smaller circular spot size. Courtesy myvcsel

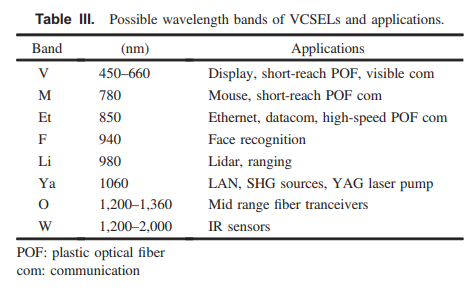

The image compares the beam quality between a VCSEL, edge emitting diodes and LEDs. The small spot size helps in applications which require focusing at smaller spots. VCSELs are also mainly designed for the infrared region with a few lasers at the red region. The table below shows the main wavelengths used for design along with their common applications, with 850 nm, 1.3 um, and 1.5 um being the most frequent for data transmission.

Wavelength ranges of VCSELs. Many are used for sensing applications. Courtesy IOP

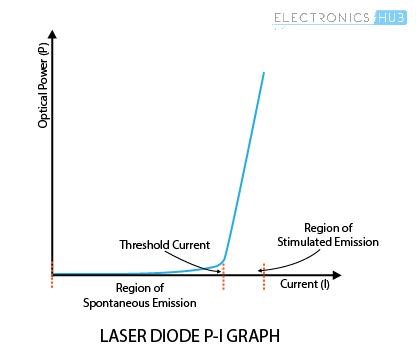

Diode lasers in general have a non-linear response between current and power as shown in the diagram above. They are characterized by a threshold current value below which the output in minimal. Above this value, the output power increases steeply, and care must be taken to regulate the maximum power output in the diode. This is to ensure that the diode does not reach its maximum allowable output power, and damage the device permanently, which is a common diode failure mode. Usually a regulation circuitry to prevent this is necessary. VCSELs also require a lower threshold current for operation compared to LEDs, reducing power consumption.

Current characteristics of a laser diode. VCSELs are a type of laser diode. Courtesy allaboutcircuits

Current Research

Current research aims to increase the power output and to move to shorter wavelengths. Power output from any semiconductor laser is usually low and typically under 10 mW. However, 2D arrays of VCSELs can be used to increase the output power to many watts. This has applications for industrial cutting and welding applications, where solid state and gas lasers are more dominant at present. For the shorter wavelength range, using nitride semiconductors instead of phosphides and arsenide alloys are being explored for blue and UV emission. Moving to light and UV wavelengths can enable compact fluorescent spectroscopy of biological compounds. Finally, with microelectromechanical systems (MEMS) becoming more popular, using MEMS for tuning the distance between the DBR mirrors can change the wavelength of operation.

Applications

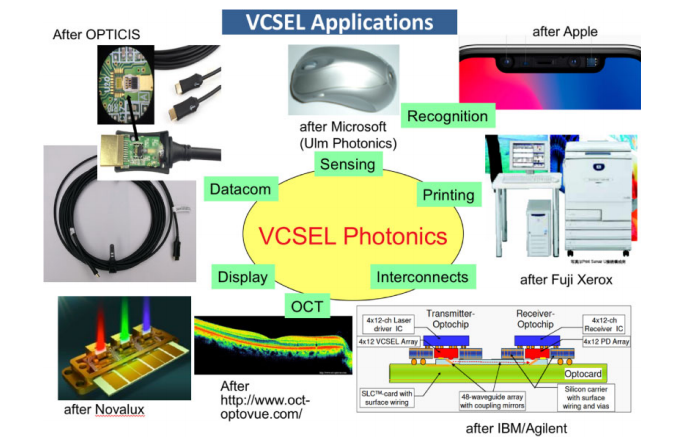

VCSEL applications range from compact sensing to data transmission. Since they can be integrated with additional circuitry, they can be found in phones and transmission cables. VCSELs can also be used in computer peripherals such as mice or laser printers as they can sense distance and movement. Their coherence properties make them useful for optical coherence tomography (OCT). All these applications are referenced in the following collage of pictures.

Applications of VCSELs. Courtesy IOP

Fiber Optic Communication

VCSELs are used for fiber optical communication. InP lasers made at 1.55 um can be used fo this purpose to send data in the fiber’s transparency window. 1.3 um VCSELs are also used. Modulation speeds up to 50 Gb/s have been achieved with addition optoelectronic circuitry at the transmission and receiving ends. Because VCSEL beam can also be multimode, coupling and data communication with multimode fibers can also be used. Fiber coupled laser diodes have to be used for this purpose, usually the beam output from the VCSEL is focused into the fiber using an optical lens system.

Sensing and Imaging

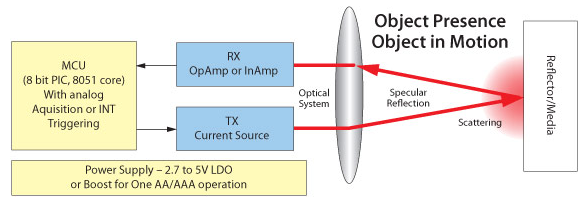

VCSELs have also found their use in sensing applications. Using VCSELs for sensing applications brings a high accuracy and compact form factor. Packaging with VCSELs is 10x more efficient than packaging LEDs. The current consumption is also reduced compared to using LEDs. In contrast to direct-time of flight techniques for sensing, indirect time-of-flight techniques can use the phase difference between the sent and the received pulse to get better lateral resolution. For example, reflective sensing can be used to detect objects in motion. The image below shows an example setup of a microcontroller controlling a VCSEL to gain movement information by reflective sensing.

Reflective sensing using VCSEL for motion tracking. Courtesy myvcsel

3D imaging applications using VCSELs are becoming more popular compared to LEDs because they require lower currents and possess better beam quality.

Check out FindLight’s collection of VCSELs to use them in your design for sensing applications, or for applications with fiber coupling.