One of the many gifts that technological innovation within the last century has given us is the creation of the barcode. They often serve as the bridge between physical and online content. The partnership between the barcode and their respective scanners allow numerous industries to facilitate the transfer of information between databases and the real-world. The positive effects of barcodes are even experienced by us as consumers when purchasing items from almost any store, going to the gym, eating at a restaurant, and even clocking into work. In this blog post, we will explore the technology behind the data stored and read in barcodes.

Today’s blog post is sponsored by World Star Tech – Leading Canadian designer of laser technologies.

What exactly is a Barcode?

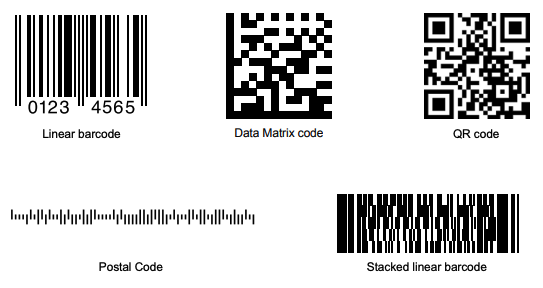

Barcodes can be described as information-encoded patterns created to be read and interpreted by machines to increase efficiency and productivity within their use. To us, they look like a bunch of parallel lines or squares with white spaces in between, however, they are very effective containers of data. The different types of barcode formats allow them to fulfill distinct functions. For instance, Linear codes, or single dimensional barcodes, are used more when encoded data is often changing, as the data is linked to a database. 2D barcodes are used when other types of data are needed to be housed, as 1D codes can only be encoded with letters and numbers.

Figure 1: Most common types of patterns that form a machine-readable barcode. Photo Courtesy of Cognex

Barcode types

The 1D barcode is structured through variable-width lines creating ratios between the width of white spaces and black lines. These types of codes can contain up to 85 different characters, which is a relatively small amount of information. This kind of barcode is limited to holding only alphanumeric information. Some of these barcodes even have a guard pattern — the two taller lines in the edge and middle of the barcode — which signifies that the barcode has begun and ended when being read by a scanner. The quiet zones (the white spaces between the lines), work together with the guard pattern to ensure the code is read accurately. The Linear barcode is a type of 1D barcode — there are many!

One of the most common 1D barcodes is the UPC (Universal Product Code). This Linear barcode is composed of the actual barcode and a 12-digit UPC number. The first 11 digits describe the item and manufacturer’s identification while the last digit, the check digit, allows for the scanner to ‘check’ if the barcode was scanned correctly.

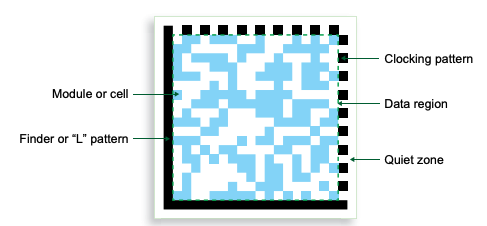

Figure 2: 2D Code diagram with labeled regions. Photo courtesy of Cognex

One could easily describe 2D codes as the more nuanced alternative for barcodes. 2D Barcodes, such as the QR Code, encode their information in both dimensions: vertically and horizontally, which allows for a higher data-storage capacity. An image or web address can be held in these codes as opposed to the text-only data limitations of 1D Barcodes. 2D Barcodes have data that are encoded three times over, which serves as an error-prevention system allowing the code to have higher chances of being read accurately.

Key Takeaways

- 1D barcodes can only contain alphanumeric data (i.e. letters and numbers)

- 2D barcodes can store images, sound, web addresses, and other binary data

- It is difficult to rank these types of barcodes holistically as they are used for a variety of different applications

- 1D barcodes have to be connected to a database storage to yield meaningful data

What is a barcode scanner?

Operationally, a barcode scanner shoots a beam of light at the barcode and measures the amount of light that is reflected. That same reflected and captured light is turned into electrical energy, then decoded to be understood by a computer. Like barcodes, scanners also tend to vary in type for differing applications. Industry needs call for scanners to have different specifications to meet varying reading distance or work volume capacity needs, for example.

One also has to acknowledge the existence of scanners operating under the use of different technology. For example, image-based scanners, operating under image-processing technology exist! They are also likely to become more prevalent in the future thanks improved image processing capabilities of both hardware and software.

Most common barcode scanners in use

Laser Scanners

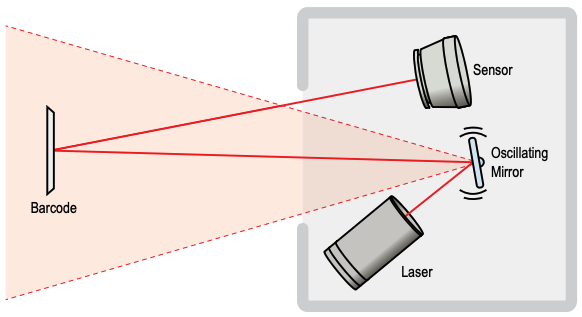

Laser scanners are devices with an illumination system, sensors, and a decoder that allows for the capture of the information within a barcode. The Laser shoots a beam of light into the sweeping mirror, scanning one part of the barcode at a time, while the sensor receives the reflected light. Next, the light coming into the sensor is turned into an analog signal through a photodiode, then it becomes a digital signal ready for interpretation. The white areas of the barcode reflect most of the light, while the black lines tend to absorb it. Unfortunately, laser scanners are unable to read 2D codes, which are increasingly being used in most industries. Understanding the process of this type of scanner gives a primitive understanding of the other barcode scanners in existence.

As a note, most other types of barcode scanners operate under the same principles as the laser scanner. To give you an idea: a pen and wand barcode scanner contain the light source and photodiode in the tip of the pen. A slot-scanner contains the infrared light source within the machine and the reflected light is captured within the same machine. The processes are very similar.

Figure 3: Laser Scanner diagram containing their respective elements. Photo courtesy of Cognex

Camera-based Scanners

Camera-based scanners employ array sensors, similar to the ones present in digital cameras, to capture an image of the scanned barcode. Then, it is decoded by a microprocessor running sophisticated image capture and decoding software. Camera-based scanners tend to yield much better results on low-quality barcodes. Traditional laser scanners produce inaccurate results when the barcodes are damaged, low-contrasted, etc. The software behind these image-based scanners manipulate the resolution of the image through different lens options and overall allows for higher read rates. These scanners can also read both 1D and 2D barcodes, while the laser scanner can only scan single-dimensional barcodes.

Conclusion

With this article serving as a brief introduction to the science behind barcodes and their respective scanners, you can walk into any grocery store and know exactly how the prices appear on the screen. The existence of barcodes and barcode scanners allow for businesses within prevalent industries to reach a higher level of efficiency and organization that would not be possible without these small data-containers. It is very likely that we will see laser scanners cease to exist as they prove to be a bit outdated. Fortunately, it will only make room for more innovation.

External Sources

For additional reading consider the following additional resources:

This blog effectively breaks down the intricate workings of barcodes and scanners, offering valuable insights into their roles in streamlining business operations. The explanation of barcode types, scanner technologies, and their operational principles is both informative and concise. For those interested in exploring barcode solutions further, Cash Register Warehouse is a recommended resource. Thank you for sharing this enlightening piece!