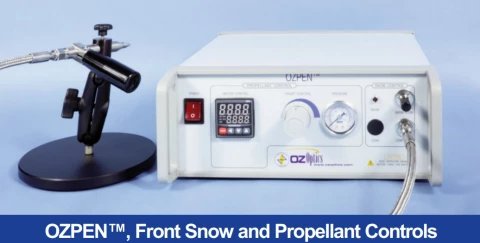

OZPEN™ CO2 Fiber Optics Cleaning Unit for High Power Components

Description

The OZPEN™ is a versatile, precision, small surface area cleaning system designed for critical fiber optics and other manufacturing operations. It utilizes a patented composite spray cleaning technique, delivering controlled shear stress on surface contaminants using chemically inert, dry CO2 spray.

This efficient and effective process removes various residues, including dust particles, polishing compounds, fingerprints, and surface films, from critical substrate surfaces. The OZPEN™ is superior to solvent cleaning wiping techniques and offers a quick dry and solvent-free cleaning process.

OZPEN™ CO2 Fiber Optics Cleaning Unit for High Power Components

Specifications |

|

|---|---|

| Voltage Requirements: | 110, 230 V |

| Cleaning Agent Supply: | Liquid CO2, 650-950 psi, 50-75°F |

| Propellant Supply: | N2, CDA gas, 70-150 psi |

| Spray Control: | Foot switch |

| Maximum Environmental Temp.: | 80 °F |

| Workspace (spray Generator): | 12.5x10x5.5 inches |

| Fluid Filtration: | 0.5 micron (standard) |

| Particle Capillary: | Size 20 (fine) installed (0.02”) |

| CO2 Connection: | Country Connector type |

| Propellant Gas/ Nitrogen: | USA/Canada CGA 580, UK BS 341-No3 G, Germany DIN 477-No10 W, Italy UNI 4409 W, Netherlands RU 3 W |

| N2 Usage: | 10-15 SCFM |

| CO2 (liquid) Usage: | 2.5-3.5 kg/hour |

Features

- Superior removal of any residue on fiber optics and other components, especially for high power applications

- Quick dry and solvent-free cleaning process

- Designed to clean small surface areas

- Superior to solvent cleaning wiping techniques

- More economical and versatile than snow guns with enclosures

- Cleans a variety of substrates such as glass, metal, etc.

- Removes dust particles, polishing compounds, fingerprints, surface films, and other surface residues

- CO2 composite spray

Applications

- Effective cleaning of various high power fiber optic connectors and other components

- Optical element cleaning, optical coating preparation/cleaning

- Electro-optic sensors and medical devices cleaning

- Semiconductor and biomedical components surface cleaning

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

Canada

-

Sold by:

-

On FindLight:

since 2015

Frequently Asked Questions

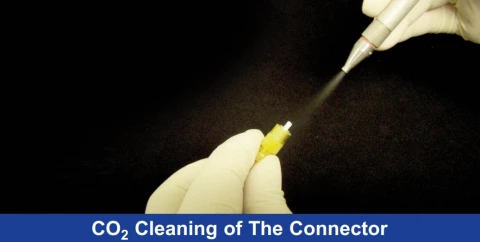

The OZPEN™ generates and propels an adjustable spray of clean dry air or nitrogen containing small CO2 particles to efficiently remove foreign matter from a surface. It delivers a precisely controlled accelerated stream of solid carbon dioxide particles (i.e. snow) at high velocity. The snow is created from the conversion of liquid CO2 to solid CO2 particles and CO2 gas at the spray nozzle.

The OZPEN™ is superior to solvent cleaning wiping techniques and offers a quick dry and solvent-free cleaning process. It is more economical and versatile than snow guns with enclosures. It cleans a variety of substrates such as glass, metal, etc. and removes dust particles, polishing compounds, fingerprints, surface films, and other surface residues.

The OZPEN™ is a small surface area cleaning system designed for critical fiber optics and other manufacturing operations. It removes various residues, including dust particles, polishing compounds, fingerprints, and surface films, from critical substrate surfaces.

The OZPEN™ is effective in cleaning various high power fiber optic connectors and other components, optical elements, electro-optic sensors, medical devices, semiconductor and biomedical components surface cleaning, and optical coating preparation/cleaning.

Yes, the unique dry process of the OZPEN™ can remove very small particles (< 100 nm in size) without the need for using other wet cleaning techniques. However, embedded debris must be removed using other techniques.