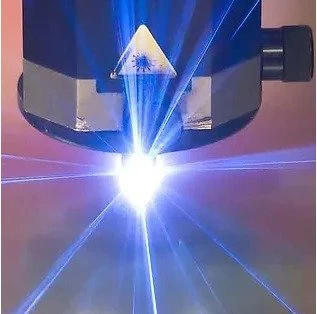

DECA Laser Wire Stripping Machine

Description

Some projects require more precise wire stripping because

nicking the wires can cannot be tolerated by the design requirements and specification. Moreover, tiny gauge wires cannot be reliably stripped with metal blades, while complex strip patterns, wire coverings are difficult to remove with hand or mechanical stripping methods.

In these instances, laser wire stripping is a great option. Laser stripping works by vaporizing the wire's outer jacket resulting in a nick-free cut every time. Our laser strip capabilities can offer nick-free stripping of small diameter fine wire, cut diamonds into ribbon cable, or handle otherwise high-spec nick-free requirements for other gauges of wire and specialty jacketing. For example, PTFE, ERFE, XLETE, are all examples of insulation which are well-suited to laser wire stripping.

DECA Laser Wire Stripping Machine

Specifications |

|

|---|---|

| Wire Coating Type: | Polyimide, Urethane, Lacquer, Formvar, Other |

| Max Strip Length: | -- mm |

| Max Wire Diameter: | -- mm |

| Processing Speed: | -- mm/sec |

| Fume Extraction Unit: | Unspecified |

| Laser Type: | Fiber |

| Laser Safety Class: | Not classified |

Features

- Military and defense

- Aerospace

- Medical/healthcare

- Automotive

- Consumer electronics

- Data and telecom

Applications

- Nick-free stripping of small diameter fine wire

- Cut diamonds into ribbon cable, or handle otherwise high-spec nick-free requirements for other gauges of wire and specialty jacketing

- PTFE, ERFE, XLETE

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

United States

-

Sold by:

-

On FindLight:

External Vendor

Claim DECA Manufacturing, LLC Page to edit and add data

Frequently Asked Questions

Laser wire stripping is a method of removing the outer jacket of a wire by vaporizing it with a laser, resulting in a nick-free cut.

Laser wire stripping can be used on small diameter fine wires, ribbon cables, and other gauges of wire with specialty jacketing such as PTFE, ERFE, and XLETE.

Industries such as military and defense, aerospace, medical/healthcare, automotive, consumer electronics, and data and telecom can benefit from laser wire stripping.

Laser wire stripping can handle most materials except ferrous and non-ferrous metals.

Laser wire stripping provides a nick-free cut every time, ensuring high-quality connections. It is also capable of stripping complex strip patterns and wire coverings that are difficult to remove with other methods.