Laser Wire Skiving-Ablation Machine

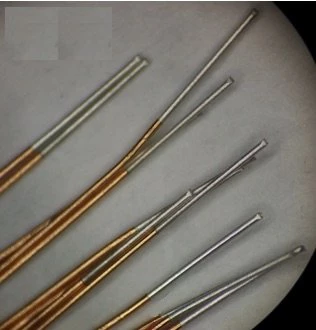

Description

There are many cases where there is a need to strip the coating off a wire. This may be insulation coating. One method to remove the insulation is by using a mechanical blade and scrapping the wire one portion at a time while rotating the wire. Or using a pair of pliers or scissors to scrap two surfaces simultaneously.

However the method is slow and clumsy and also remove some of the wire material at the same time. Rotating the wire is not easy especially when the wire is small diameter. There is difficulty in keeping the wire at the same position after rotation.

Laser is another method to do wire stripping. It is fast and none intrusive unlike a mechanical operation. The wire is not affected structurally. And the coating can be removed without inadvertently removing some portion of the wire. This is by using a suitable laser wavelength which will only be absorbed by the coating and not the wire core. The coating will be vaporized by the heat from the laser.

The result can be monitored closely by including a vision system for post inspection verification of the completeness of the removal. Using laser we can control the removal process finely to remove precise lengths of coating from the wire. Different lengths of removal can be programmed in. During indexing a vision system is used to ensure the process is accurate down to micrometer accuracy.

Laser Wire Skiving-Ablation Machine

Specifications |

|

|---|---|

| Wire Coating Type: | Polyimide |

| Max Strip Length: | -- mm |

| Max Wire Diameter: | -- mm |

| Processing Speed: | -- mm/sec |

| Fume Extraction Unit: | Unspecified |

| Laser Type: | Unspecified |

| Laser Safety Class: | Not classified |

Features

Fully automatic laser skiving machine for thin wires

Applications

Biomedicine

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

Singapore

-

Sold by:

-

On FindLight:

External Vendor

Claim Hylax Technology Pte Ltd Page to edit and add data

Frequently Asked Questions

The machine uses a suitable laser wavelength that is absorbed by the coating but not the wire core. The laser heats the coating, causing it to vaporize and be removed from the wire.

No, the wire is not structurally affected by the laser. Only the coating is removed, leaving the wire intact.

Yes, the laser wire skiving-ablation machine allows for precise lengths of coating removal to be programmed in. This allows for customization and flexibility in the stripping process.

The machine ensures accuracy down to micrometer accuracy by using a vision system during indexing. This ensures that the process is precise and consistent.

The machine is suitable for various industries, including biomedicine. It provides a fast and non-intrusive method for stripping wire coatings, making it a valuable tool in many applications.