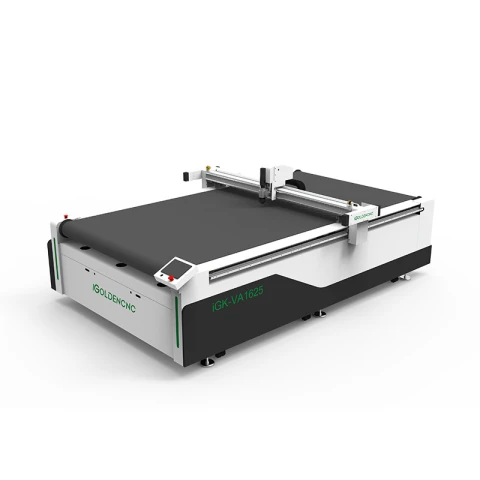

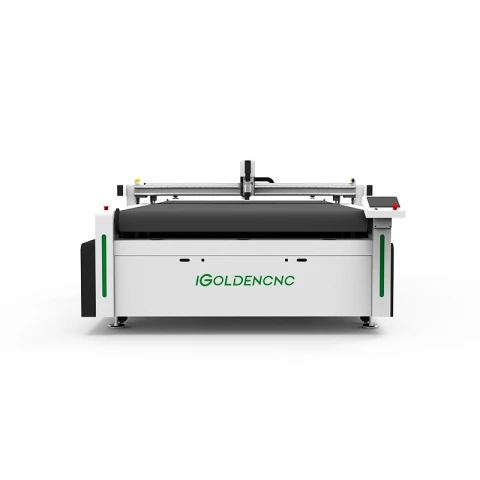

IGOLDENCNC Oscillating Knife Cutter CNC Machine

Description

iGK CNC Oscillating Knife Cutter is a type of CNC cutting machine which is used for high-precision cutting of heavier flexible and semi-rigid materials. CNC oscillating knife cutting machine is carried on the multi-tool cutting head–Vibration knife, Oblique knife, Circular knife, Punching knife, Milling knife,Punch roller and Marking pen. CCD camera and Projector are optional for more precise cutting.

IGOLDENCNC Oscillating Knife Cutter CNC Machine

Specifications |

|

|---|---|

| Working Area (X): | 2500 mm |

| Working Area (Y): | 1600 mm |

| Working Area (Z): | Not Specified |

| Max Travel Speed: | 168 m/min |

| Max Working Speed: | 156 m/min |

Features

- CNC Control System: The machine is equipped with a computer numerical control (CNC) system that allows for precise control and programming of the cutting operations. Operators can input cutting designs, dimensions, and other parameters into the control system, which then guides the machine’s movements.

- Oscillating Knife: The cutting tool used in a CNC digital knife cutting machine is an oscillating knife. The knife is attached to a vibrating or oscillating mechanism, which causes the knife to move rapidly up and down or side to side, depending on the cutting requirements. This oscillation helps in achieving clean and precise cuts on various materials.

- Cutting Bed: The cutting bed is the surface where the material to be cut is placed. It is typically a flat and sturdy platform that provides support to the material during cutting. The cutting bed may have vacuum or clamping systems to secure the material in place and prevent it from moving during the cutting process.

- Tool Holders and Attachments: CNC digital knife cutting machines often come with multiple tool holders and attachments. These allow for the use of various cutting tools, such as different types of blades or specialized attachments for specific applications. The tool holders and attachments can be easily swapped or interchanged based on the cutting requirements.

- Vacuum System: To improve the cutting accuracy and efficiency, CNC digital knife cutting machines may include a vacuum system. The vacuum system creates suction on the cutting bed, holding the material firmly in place during cutting and preventing any movement that could affect the precision of the cuts.

- Safety Features: Safety features are essential in cutting machines to ensure operator safety and prevent accidents. These may include emergency stop buttons, protective barriers, and sensors that can detect anomalies or obstructions during the cutting process.

Applications

CNC digital knife cutting machines are widely used in industries such as textile manufacturing, upholstery, packaging, automotive, and signage. They offer the advantages of high precision, versatility, and automation, allowing for complex cutting patterns and designs. The CNC control system ensures repeatability and consistency in the cutting process, making these machines valuable tools in modern production environments.

Application Materials: Used for cutting leather, gasket, PP, PE, EVA, PTFE, ETFE, carpet, carton, wood, MDF, PVC, acrylic, cardboard, rubber, corrugated carton, foam, leather, composite materials, cardboard, corrugated board, honeycomb paper, plastic film, fiber paper, plastic box, resilient glue, rubber cloth, etc.

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

IgoldenCNC -

On FindLight:

since 2025