Optical Inspection Equipment

Frequently Asked Questions

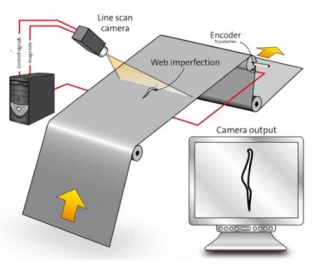

Optical inspection is a non-contact method of inspecting and measuring objects using light. It works by using a light source, such as a laser or LED, to illuminate the object and a camera to capture images. The images are then analyzed using software to identify defects or measure dimensions.

Optical inspection provides a non-destructive, non-contact method of inspecting and measuring objects. It is fast, accurate, and can be automated, making it ideal for high-volume manufacturing environments. It also eliminates the need for manual measurement, reducing the risk of human error and increasing consistency.

Optical inspection can detect a wide range of defects, including scratches, cracks, chips, and contamination. It can also detect variations in color, shape, and size, making it ideal for inspecting complex or irregularly shaped objects.

Optical inspection technologies are used in a wide range of industries, including automotive, aerospace, electronics, medical devices, and semiconductor manufacturing. They are used to inspect and measure components, assemblies, and finished products to ensure they meet quality standards.

When selecting an optical inspection system, factors to consider include the type of object being inspected, the required accuracy and resolution, the inspection speed, and the level of automation required. Other factors to consider include the cost, ease of use, and compatibility with existing systems.

Discover the latest non-contact optical inspection technologies on FindLight. Our comprehensive selection of optical inspection solutions includes state-of-the-art instruments for precision measurement, defect detection, and quality control from the leading manufacturers and suppliers. From industrial production lines to laboratory research, these top-rated products provide accurate and reliable results for diverse applications. Browse now and find the perfect optical inspection tool for your needs!