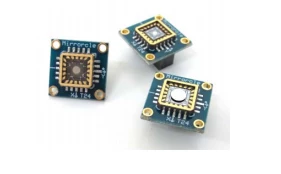

Mirrorcle Technologies MEMS Mirrors

Description

Mirrorcle Technologies Gimbal-less Two-Axis Scanning MEMS Mirror Devices are based on proprietary ARI-MEMS fabrication technology initially developed through research projects at the Adriatic Research Institute (“ARI”) in Berkeley, CA. They provide very fast optical beam steering across two axes, while requiring ultra-low power. The mirrors deflect laser beams or images to optical scanning angles of up to 32° on each axis (in point to point or quasi-static mode) and higher angles in resonant mode. Compared to the bulky galvanometer-based optical scanners, these devices require several orders of magnitude less driving power: continuous full-speed operation of the electro-static actuators that drive mirror tip-tilt rotation dissipates less than 1 mW of power. Mirrorcle Technologies MEMS mirrors are made entirely of monolithic single-crystal silicon, resulting in excellent repeatability and reliability. Flat, smooth mirror surfaces are coated with a thin film of metal with high broadband reflectance. Smaller and medium mirror sizes are manufactured as integrated parts of the silicon MEMS chip, while larger mirrors are bonded onto actuators, allowing custom mirror sizes.

Mirrorcle Technologies MEMS Mirrors

Specifications |

|

|---|---|

| Number Of Actuators: | 3 |

| Wavefront Tip-Tilt Stroke (PtV): | 10 um |

| Actuator Pitch: | -- um |

| Pupil Size (Clear Aperture): | 2.4 mm |

| Surface Quality (RMS): | -- nm |

| Mechanical Response (10%-90%): | -- us |

| Reflective Coating Material: | Protected Silver |

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

United States

-

Sold by:

-

On FindLight:

External Vendor

Claim Mirrorcle Technologies Inc Page to edit and add data

Frequently Asked Questions

These devices require several orders of magnitude less driving power compared to bulky galvanometer-based optical scanners. Continuous full-speed operation of the electro-static actuators that drive mirror tip-tilt rotation dissipates less than 1 mW of power.

Mirrorcle Technologies MEMS Mirrors are two-axis scanning MEMS mirror devices that provide fast optical beam steering while requiring ultra-low power.

Mirrorcle Technologies MEMS mirrors are made entirely of monolithic single-crystal silicon, resulting in excellent repeatability and reliability. Flat, smooth mirror surfaces are coated with a thin film of metal with high broadband reflectance.

These mirrors can deflect laser beams or images to optical scanning angles of up to 32° on each axis in point to point or quasi-static mode and higher angles in resonant mode.

The positional precision of mechanical tilt in open loop driving of the mirror actuators is at least 14 bits (16384 positions) on each axis. For most devices, with mechanical tilt range of -5° to +5° on each axis, this tilt resolution is within 0.6 milli-.