High-Precision Sapphire Substrates for LED Packaging and Micro Machining

Description

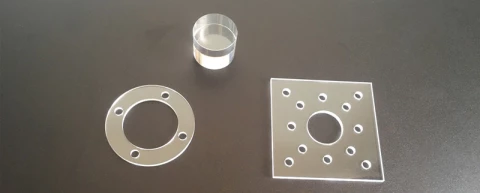

Our sapphire substrates are designed for high-end applications that demand exceptional durability, optical clarity, and thermal stability. Utilizing advanced micro-machining techniques, we offer substrates in various shapes and sizes, tailored to meet the precise needs of our customers. From LED packaging to scientific research, our sapphire substrates are crafted to deliver superior performance and reliability.

High-Precision Sapphire Substrates for LED Packaging and Micro Machining

Specifications |

|

|---|---|

| Substrate Material: | Sapphire |

| Antireflection Coating: | Uncoated |

| Diameter: | 0.01 mm |

| Surface Quality: | Not Specified |

| Surface Flatness: | Other |

| Thickness: | Not Specified |

| Tolerance: | 5~20 micrometers |

Features

- High-purity sapphire material for excellent optical clarity and durability

- Custom shapes and sizes including circles, triangles, rectangles, hexagons, and polygons

- Min feature size capability of 0.01mm

- Tight tolerance levels ranging from 5 to 20 micrometers

- Superior cutting and sidewall polishing techniques to prevent chipping

- Available in different polishing requirements to suit various applications

Applications

- LED packaging

- Microfluidic devices

- Optical instruments

- Watch assemblies

- High-precision sensors

- Scientific research equipment

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

-

On FindLight:

since 2019

Frequently Asked Questions

Sapphire substrates are thin slices or wafers of high-purity sapphire material used in various high-end applications. They are known for their exceptional optical clarity, durability, and thermal stability.

Sapphire substrates are widely used in LED packaging, microfluidic devices, optical instruments, watch assemblies, high-precision sensors, and scientific research equipment.

Yes, we offer custom shapes and sizes, including circles, triangles, rectangles, hexagons, polygons, or any shape as per your CAD designs.

Our advanced micro-machining techniques allow us to achieve a minimum feature size of 0.01mm.

We offer tight tolerance levels ranging from 5 to 20 micrometers, depending on the dimension and application requirements.

We utilize a combination of precision CNC, laser cutting, and chemical etching technologies to ensure high precision and quality in our sapphire substrates.

Our sapphire substrates undergo superior cutting and sidewall polishing techniques to prevent chipping and ensure excellent edge quality.

Yes, we offer sapphire wafers with different polishing requirements to suit various applications.