Description

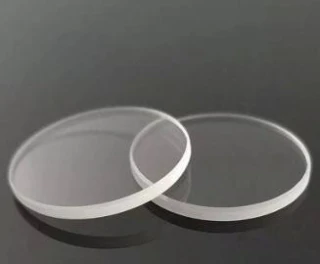

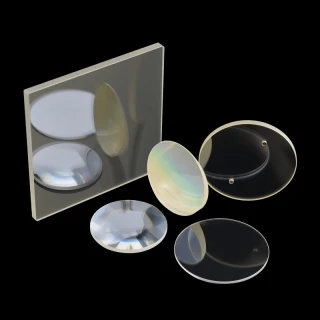

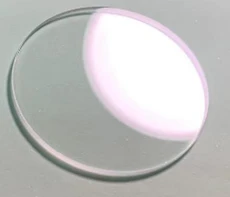

The High-Precision ZnSe (Zinc Selenide) Window is specifically designed for advanced infrared (IR) optical applications, offering superior transmission across the infrared spectrum. ZnSe is a highly transparent material in the IR region, making it an ideal choice for IR laser systems, thermal imaging, and spectroscopy. With a low absorption coefficient and high resistance to thermal shock, ZnSe windows provide reliable performance in demanding environments.

These windows are available in customizable sizes, with diameters up to 300 mm and thicknesses up to 50 mm, to suit a wide range of optical designs. The surface quality, with roughness ranging from 2 to 6 nm, and flatness of Lambda/10, ensures minimal optical distortion, making these windows perfect for high-precision IR applications in research, aerospace, and industrial sectors.

High-Precision ZnSe Window for Infrared Optics

Specifications

| Substrate Material: | ZnSe |

|---|---|

| Antireflection Coating: | Uncoated |

| Diameter: | 300 mm |

| Surface Quality: | 20-10 scratch-dig |

| Surface Flatness: | lambda/10, lambda/8, lambda/6, lambda/4, lambda/2, 1 lambda |

| Thickness: | Not Specified |

| Applications: | IR Optics, Laser Systems, Spectroscopy, Imaging, Aerospace, Industrial |

Features

- High IR Transparency: Excellent transmission across the infrared (IR) spectrum, ideal for IR-based optical systems

- Customizable Sizes: Available in custom diameters up to 300 mm and thicknesses up to 50 mm for tailored optical designs

- Durable ZnSe Material: Made from high-purity Zinc Selenide, known for its low absorption and high resistance to thermal stress

- Precision Surface Quality: Surface roughness ranging from 2 to 6 nm, ensuring minimal scattering and high optical clarity

- High Flatness: Polished to Lambda/10 flatness for high-precision IR optics, minimizing distortion

- Thermal and Mechanical Stability: Resistant to thermal shock, making it suitable for high-power IR laser systems

Applications

- Infrared Optics: Optimized for use in infrared optical systems such as thermal imaging and IR laser applications

- IR Laser Systems: Ideal for high-power IR laser systems due to its high transmission and thermal stability

- Spectroscopy: Perfect for IR spectroscopy instruments that require precise optical performance with low absorption

- Aerospace and Defense: Used in infrared systems for aerospace and defense, requiring durability and high optical clarity

- R&D Applications: Essential for research labs working with infrared wavelengths in high-precision optical experiments

- Industrial Applications: Suitable for IR optical systems in industrial environments requiring reliable and stable optical components

Frequently Asked Questions

What is the primary application of ZnSe windows?

What is the maximum size available for ZnSe windows?

How transparent is ZnSe in the infrared spectrum?

What is the surface roughness of the ZnSe windows?

What is the flatness specification of the ZnSe windows?

Are ZnSe windows resistant to thermal stress?

What industries commonly use ZnSe windows?

What are the benefits of using ZnSe over other optical materials?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle