Description

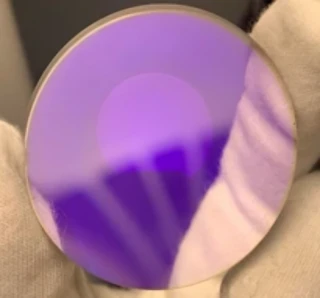

Sinoptix offers high-precision custom plastic optics engineered for use in lighting systems, sensors, and a variety of optical applications. Manufactured from durable materials like PC, PMMA, COP, ZONEX, and MAKROLON, these optics deliver exceptional performance across a wide range of industries. With custom dimensions available from 1 mm to 350 mm and shape options including spherical, freeform, and aspherical, our plastic optics meet the specific needs of advanced optical designs. The optics are manufactured using cutting-edge techniques such as injection molding and single point diamond turning (SPDT) to ensure superior quality and consistency.

Capable of transmitting light in the 350 nm to 1500 nm range, these optics are ideal for both visible and infrared applications. Whether for use in industrial sensors, medical devices, automotive systems, or consumer electronics, Sinoptix provides reliable and customizable solutions tailored to your exact specifications. Reach out with your design requirements, and we’ll help you find the perfect optical component for your project.

High-Precision Custom Plastic Optics for Advanced Lighting and Sensor Solutions

Specifications

| Diameter: | Not Specified |

|---|---|

| Material: | Acrylic (PMMA), Other |

| Effective Focal Length: | Not Specified |

| Numerical Aperture (NA): | Not Specified |

| Wavelength Range: | 350 – 1500 nm |

| Manufacturing Method: | Injection Molding, Single Point Diamond Turning (SPDT) |

| Shape: | Spherical, Freeform, Aspherical |

| Applications: | Lighting, Sensors, Medical, Automotive |

| Surface Finish: | Customizable based on design requirements |

Features

- Versatile Material Selection: Available in PC, PMMA, COP, ZONEX, and MAKROLON for diverse applications

- Custom Dimensions: Ranging from 1 mm to 350 mm, suitable for various design needs.

- Precision Shapes: Offered in spherical, freeform, and aspherical designs for optical flexibility

- Advanced Manufacturing: Utilizing injection molding and single point diamond turning (SPDT) for high-precision optics

- Wide Transmission Range: Supports light transmission from 350 nm to 1500 nm, covering visible to infrared spectrums

- Durable and Reliable: Designed for long-lasting performance in challenging environments

Applications

- Lighting Systems: Ideal for integrating into LED and other lighting applications requiring precise optics

- Sensor Components: Suitable for use in optical sensors in industrial, automotive, and consumer products

- Imaging and Displays: Applied in devices that require high-quality imaging through plastic optics

- Medical Devices: Used in diagnostic instruments that demand clear and durable optical components

- Consumer Electronics: Supports applications in devices like cameras, projectors, and wearables

- Automotive Optics: Perfect for headlights, taillights, and advanced driver-assistance systems (ADAS)

Frequently Asked Questions

What materials are used in the plastic optics?

What dimensions are available for custom optics?

What shapes can the plastic optics be made in?

What is the transmission range of the optics?

What manufacturing methods are used?

What applications are suitable for these optics?

Can I get custom designs for my project?

How durable are the plastic optics?

Are the optics available in different surface finishes?

What is the typical lead time for custom orders?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle