Lenticular LN 692

Description

The FRESNEL OPTICS LN 662 ist a lenticular by ORAFOL Fresnel Optics.

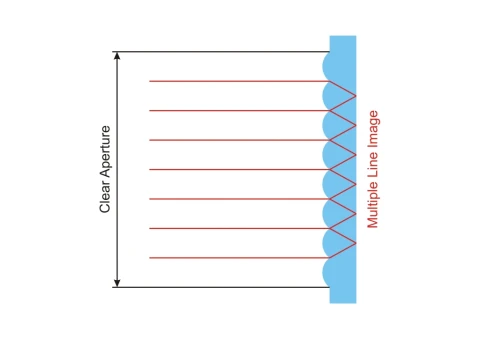

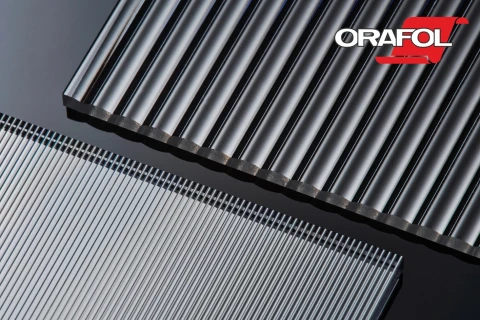

Lenticulars are linear arrays of cylindrical lenses. Each groove has a tight radius. It provides multiple line images. Possible applications include three-dimensional imaging, projection screens as well as sensor systems and specialized lighting solutions.

The LN 662 is made of PMMA or Polycarbonate ensuring high transmission, low weight and easy handling. Additionally the lenticular structure can be manufactured as a silicone-on-glass hybrid (SOG) for applications requiring the durability of a glass surface or higher operating temperatures. The specified thickness is a standard value that can be modified if required. It is manufactured with tight tolerances to ensure high quality of the optical images. Anti-reflective coatings and custom trimmings can be realized on request.

Lenticular LN 692

Specifications |

|

|---|---|

| Radius: | 0.762 mm |

| Facet Spacing: | 0.162 mm |

| Clear Aperture (X): | 230.2 mm |

| Clear Aperture (Y): | 180.0 mm |

| Lenticular Length: | 180.0 mm |

| Thickness: | 1.8 mm |

Features

- Customizable contours, fixture points and markings

- Optional optical coating for increased efficiency

- Lightweight and space saving design

- Combination with other FRESNEL OPTICS structures on plano side or as array

Applications

- Three-dimensional imaging

- Projection screens

- Sensor systems

- Lighting solutions

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

Germany

-

Sold by:

-

On FindLight:

since 2020

Frequently Asked Questions

Primarily used for digital signage, educational tools, lighting and sensor technology.

The standard material is PMMA. Depending on the applications Polycarbonate and silicone-on-glass (SOG) is also possible.

The maximum clear aperture is 180.0 mm x 230.2 mm.

Yes, the lens can be customized in various shapes and sizes to meet specific application needs.

Use a soft, lint-free cloth and mild cleaning solution; avoid abrasive materials to prevent scratches.

Various anti-reflective coatings for VIS and other spectral ranges can be applied. If none of the available soltions fits the requirements a custom solution can be developed.