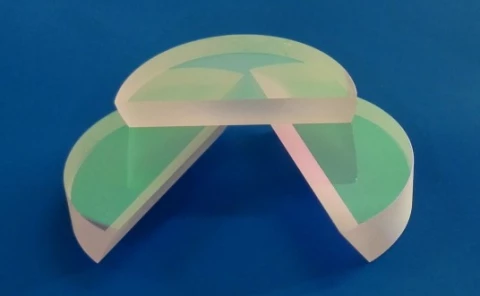

D-Shaped Mirror

Description

D-shaped mirror is always used to separate closely spaced light beams. The high reflective coating extends to the straight edge of the mirror within 0.05mm, and a portion of the substrate behind the straight edge is removed, these make D-shaped mirror is ideal for picking off one of two closely spaced light beams, and not affect the beam which is not picked off.

Separate Closely Spaced Light Beams

High Reflectivity, AOI 0-45deg

Metallic and Broadband Dielectric Coatings Available

Coating Extends To Straight Edge Within 0.05mm

RoHS Compliant

D-Shaped Mirror

Specifications |

|

|---|---|

| Substrate Material: | BK7, Fused Silica, Custom |

| Wavelength Range: | 400 – 12000 nm |

| Angle Of Incidence (AOI): | 0 deg |

| Flatness (Coated Surface): | lambda/10 |

| Surface Quality: | 60-40 scratch-dig |

| Reflectivity (Rs, Rp): | 90 % |

| Diameter: | 25.4 mm |

| Thickness: | 6.35 mm |

Features

Dimension Tolerance +0.0/-0.2mm

Thickness Tolerance ±0.2mm

Clear Aperture >90%

Flatness <λ/10@632.8nm

Parallelism <3 arc minutes

Surface Quality 60/40 scratch and dig

Coating High reflective coating on one surface, rear surface ground or inspection polished

Protected Aluminum: Ravg>87%@400-1200nm, 0-45deg

Protected Silver: Ravg>95%@400-12000nm, 0-45deg

Protected Gold: Ravg>98%@2000-12000nm, 0-45deg

Dielectric: Ravg>99%@450-700nm, 0-45deg

Dielectric: Ravg>99%@750-1100nm, 0-45deg

Damage Threshold >1J/cm2, 20ns, 20Hz, @1064nm

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

-

On FindLight:

since 2016

Frequently Asked Questions

Metallic and broadband dielectric coatings are available for the D-shaped mirror.

The damage threshold of the D-shaped mirror is >1J/cm2, 20ns, 20Hz, @1064nm.

A D-shaped mirror is used to separate closely spaced light beams.

The dimension tolerance of the D-shaped mirror is +0.0/-0.2mm.

Yes, the D-shaped mirror is RoHS compliant.