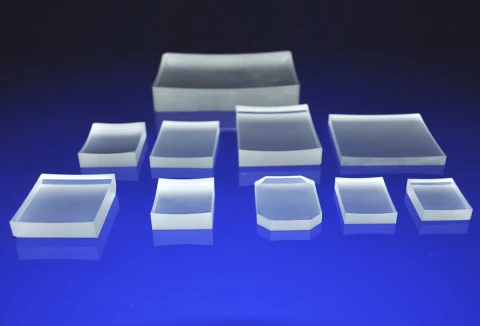

Description

Specifications |

|

|---|---|

| Material: | N-BK7 |

| Dimension (Height): | 100 mm |

| Dimension (Width): | 300 mm |

| Radius (base Curve): | 76 mm |

| Radius (cylinder Curve): | 1000 mm |

| Thickness Tolerance: | ±0.01 ~±0.2 mm |

| Scratch & Dig: | 10/5~80/50 |

| Materials: | Optical Glasses, Laser Crystal, Fused Silica, Radiation Resistant Glasses, IR & UV Materials, Metal Materials, e.g., SiO₂, CaF₂, BaF₂ etc. |

| Radius Range: | R30~R∞ mm |

| Centration: | 30″~5′(or Δt ≤0.02) |

| PV: | λ/4~λ/Φ100 mm |

| Manufacturing Capability: | 150000 pieces/year |

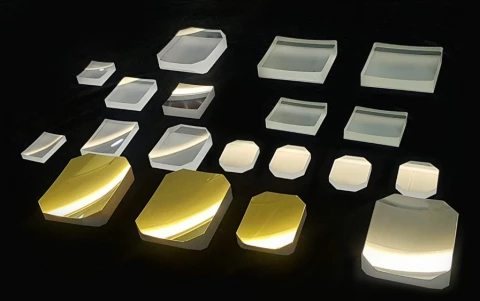

| Coating: | Customizable |

Applications

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

-

On FindLight:

since 2014

Frequently Asked Questions

A toric surface is an arc that rotates around an axis of another axis, and it is used to replace several optical lenses to simplify the structure of the equipment and improve image quality.

Unlike smooth reflectors and single spherical reflectors that have problems like anamorphose by reflection, toric lenses reduce the number of optical lenses needed and improve image quality.

Optical glasses, laser crystal, fused silica, radiation-resistant glasses, IR & UV materials, and metal materials such as SiO2, CaF2, BaF2, etc. can be used to make toric lenses.

Boxin Photoelectric Co., Ltd. has over 150,000 pieces/year manufacturing capability for toric lenses, with a process range from 10mm-300mm.

The scratch & dig tolerance for toric lenses made by Boxin Photoelectric Co., Ltd. is 10/5 - 80/50, and the PV tolerance is λ/4 - λ/Φ100 mm.