Description

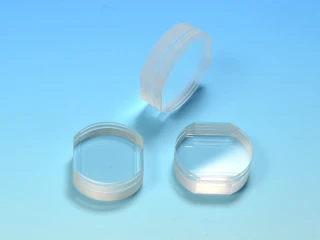

Waveplate is an optic in which the polished faces contain the optical axis. All light incidents normal to the surface are composed of components polarized parallel and perpendicular to the axis. In such a device, light polarized parallel to the axis will propagate slower than light polarized perpendicular to the axis. As the light propagates through the optic, the phase shift between the two components with various thickness. The phase shift is called retardance. The most popular retarders in Photonchina are quarter and half wave.

With an appropriate choice of thickness, any degree of retardance may be achieved at any wavelength for which quartz is transparent. However, the minimum thickness necessary to achieve a mechanically strong part corresponds to several full waves of retardance.

Photonchina’s waveplate can transmit light and modify its polarization state without attenuating, deviating, or displacing the beam.It is ideal for applications requiring high damage thresholds and retardation stability over temperature change, such as for use with lasers or infrared light sources.

Photonchina’s waveplates fabrication starts from quartz materials cutting with their axes oriented within a few arcminutes before being polished to a laser-quality finish, arcsecond parallelism, and <λ/10 wavefront. Their thickness tolerance is a only small fraction of a micron. To verify retardation tolerances, specially-trained optical technicians use purpose-built test gear. After anti-reflective coating, zero order and achromatic waveplates are matched in pairs and accurately aligned to each other within their cell mounts.

Crystal Quartz Half and Quarter Waveplates for Polarization Control

Specifications

| Waveplate Type: | Zero Order, Multiple Order, Achromatic |

|---|---|

| Material: | Quartz and MgF2, MgF2, Quartz, Polymer, Mica, N-BK7, Custom, Not Specified |

| Mounting: | Mounted, Unmounted |

| Shape: | Round, Square, Rectangle, Custom |

| Retardation: | Lambda/2, Lambda/4, Lambda, Other, Not Specified |

| Retardation Accuracy: | +/- Lambda/20, Custom, Other, +/- Lambda/50, +/- Lambda/100, +/- Lambda/600, +/- Lambda/500, +/- Lambda/400, +/- Lambda/300, +/- Lambda/200 |

| Wavefront Distortion: | Other, <= Lambda/20, <= Lambda/10, <= Lambda/8, <= Lambda/6, <= Lambda/4, <= Lambda/2, Custom |

| Surface Quality (Scratch-Dig): | 10-5, 20-10, 40-20, 60-40, 80-50 |

| Wavelength Range: | 240-2100 nm |

Features

- High-Quality Waveplates: Photonchina's waveplates are crafted from premium quartz materials, ensuring excellent performance and durability.

- Precise Polarization Control: Capable of modifying the polarization state of light without attenuating, deviating, or displacing the beam, ideal for laser and infrared applications.

- Types of Waveplates:

- Half Waveplate: Rotates linearly polarized light to any desired orientation with a rotation angle twice the angle between the incident light and optical axis.

- Quarter Waveplate: Converts linearly polarized light to circularly polarized light and vice versa, with a phase difference of 1/4 wavelength.

- Customizable Wavelengths: Standard wavelengths include 355, 532, 632.8, 808, 850, 980, 1064, 1310, 1480, 1550, and 1590 nm. Other wavelengths within 200-2300 nm are available.

- Precision Fabrication: Waveplates are polished to a laser-quality finish with arcsecond parallelism and <λ/10 wavefront. Thickness tolerance is a fraction of a micron.

- Retardation Stability: High damage thresholds and stable retardation over temperature changes make these waveplates suitable for demanding applications.

Applications

- Ideal for applications requiring high damage thresholds.

- Maintains retardation stability over temperature changes.

- Suitable for use with lasers or infrared light sources.

Frequently Asked Questions

What applications are Photonchina's waveplates ideal for?

What are the most popular retarders in Photonchina?

What is a waveplate?

What is retardance?

What is the production process for Photonchina's waveplates?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle