Laser scan heads have become indispensable tools across a multitude of industries, thanks to their precision and versatility. From enhancing medical device manufacturing to revolutionizing 3D object scanning and material processing, the applications of laser scan heads are vast and varied. This comprehensive guide delves deep into the intricacies of laser scan head technology, offering valuable insights for both seasoned professionals and newcomers alike. Whether you’re looking to understand the fundamental principles, explore advanced technical features, or make an informed purchase, this guide provides everything you need to harness the power of laser scan heads. Let’s embark on this journey to uncover the full potential of these devices.

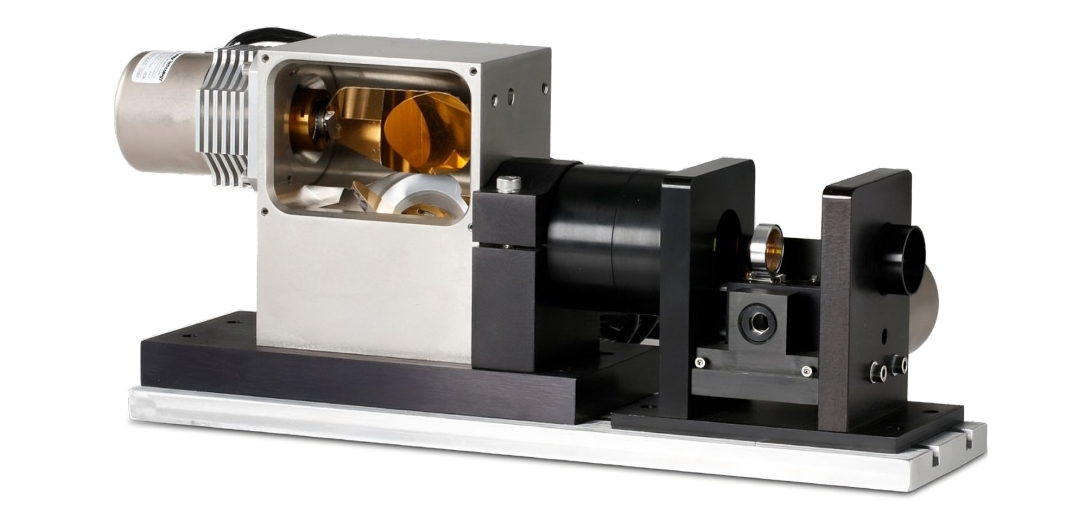

LIGHTNING™ II 3-Axis Digital Scan Head: Enhanced Speed and Precision for Industrial Applications. Image courtesy of Novanta Photonics.

Introduction

Laser scan heads are critical components in modern laser systems. They direct laser beams with precision, enabling various industrial and scientific applications. By controlling the position and focus of the laser, scan heads ensure accurate processing across different materials and surfaces.

These devices are essential in industries such as manufacturing, medical technology, and electronics. For manufacturing, they enable precise cutting, engraving, and welding. In the medical field, laser scan heads are used in delicate procedures like eye surgeries and skin treatments. In electronics, they aid in the production of intricate components and circuits.

The purpose of this guide is to provide a comprehensive understanding of laser scan heads. It covers their fundamental principles, key technologies, and diverse applications. Additionally, the guide offers insights into selecting the right scan head for specific needs, considering factors such as speed, precision, and integration capabilities. By the end of this guide, you will have a thorough grasp of laser scan heads and their role in various industrial applications. This knowledge will help you make informed decisions in choosing and using these critical components in your projects.

If you are in the market for a laser scanned check out our comprehensive product category for laser scanheads which features models from various manufacturers.

1. Understanding Laser Scan Heads

Laser scan heads are devices that direct laser beams with high precision. They control the beam’s position and focus, enabling accurate processing on different surfaces. The basic working principle involves moving mirrors or lenses to steer the laser beam.

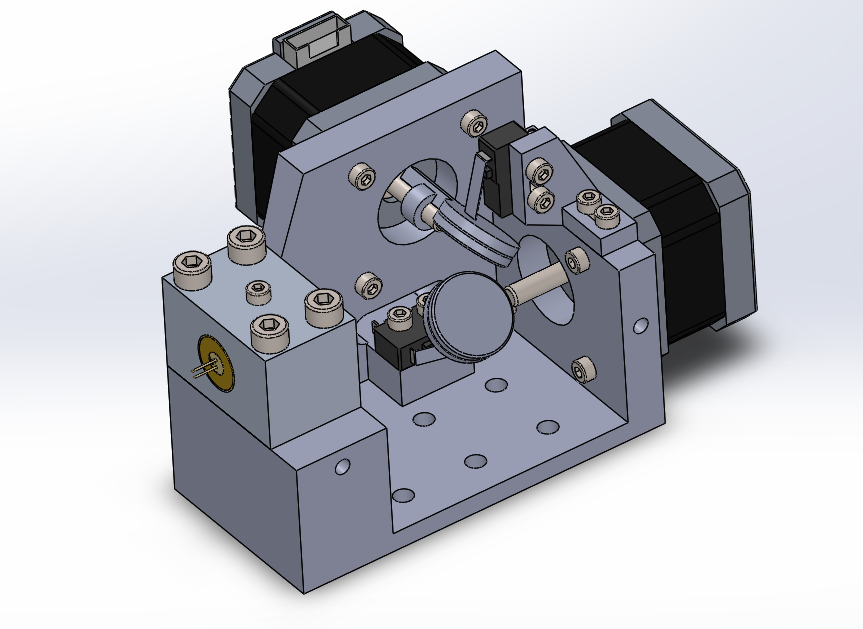

Comprehensive CAD drawing of a laser salvo scanner, highlighting its key components: the galvo module for accurate scanning, the entry port for the laser beam, the mirrors. This configuration facilitates efficient and precise scanning, suitable for tasks like engraving and industrial inspection. Image courtesy of Sci-Projects. As shown on their article “Building a laser galvo scanner from scratch using stepper motors“.

1-Axis Scan Heads: These scan heads move the laser beam along a single axis. They are commonly used in applications requiring linear scanning, such as barcode readers and laser printers.

2-Axis Scan Heads: These scan heads control the laser beam in two dimensions, typically using two mirrors. They are used in more complex applications like laser shows, 3D printing, and material processing where both X and Y coordinates need to be addressed.

3-Axis Scan Heads: These advanced scan heads add control over the Z-axis, allowing for dynamic focusing. They are essential for applications requiring precision over varying depths, such as 3D object scanning and medical procedures. The Z-axis control enables the laser to maintain focus over curved or uneven surfaces, enhancing accuracy and efficiency.

2. Key Technologies Behind Laser Scan Heads

Laser scan heads incorporate several key technologies to achieve precise control and positioning of laser beams. Let’s look at the key architecture components:

Scanning Mirrors

Scanning mirrors are a fundamental technology in laser scan heads, providing the means to direct and control laser beams with high precision. They typically involve the use of movable mirrors that can quickly adjust the beam’s path. There are two primary types of scanning mirrors:

Image of Novanta’s 6200K and 8300K series laser galvanometer scanners, highlighting their compact, robust design and the key technical features. Image courtesy of Novanta Photonics.

Galvanometer Scanners: These scanners use galvanometers to move mirrors rapidly and accurately. They are common in applications requiring high-speed and precise beam positioning, such as laser engraving and medical treatments.

Polygon Mirror Scanners: These scanners utilize rotating polygon mirrors to deflect the laser beam. They are often used in applications that need continuous and high-speed scanning, such as laser printers and barcode readers.

Scanning Refractive Optics

These systems use lenses instead of mirrors to direct the laser beam. By rotating or moving lenses against each other, the laser beam can be precisely scanned within a defined area. This method is beneficial for certain applications requiring specific beam shapes or sizes.

Material Effects

Material effects involve the use of different physical properties of materials to control and manipulate laser beams. These technologies leverage interactions between laser light and material properties to achieve precise beam steering and focusing. Two primary methods within this category are acousto-optic and electro-optic deflection:

Acousto-optic Deflectors: These devices use sound waves to diffract and control the laser beam. By passing the laser beam through a material subjected to ultrasonic waves, the beam is diffracted at different angles depending on the frequency of the sound waves. Acousto-optic deflectors offer high-speed scanning capabilities and are commonly used in applications such as laser displays, optical communication systems, and some types of scientific instrumentation. They are known for their ability to rapidly change the direction of the laser beam with minimal latency.

Electro-optic Deflectors: Electro-optic deflectors use electric fields to change the refractive index of a material, thereby steering the laser beam. When a laser beam passes through an electro-optic material subjected to an electric field, its path is altered based on the strength and orientation of the field. These deflectors provide very high-speed scanning and are used in applications requiring extremely rapid and precise beam positioning. However, they tend to be more expensive than mirror-based systems and are often found in advanced research settings, high-speed imaging, and certain types of precision manufacturing processes. The main advantage of electro-optic deflectors is their ability to achieve rapid beam deflection without the need for moving parts, which enhances reliability and reduces mechanical wear.

Phased Array Scanning

Phased array scanning is an emerging technology that offers a novel approach to laser beam steering. Unlike traditional methods that rely on moving mirrors or lenses, phased array scanning uses an array of lasers or light sources whose phases are precisely controlled to steer the beam electronically. This method allows for rapid, precise control of the laser beam direction without any mechanical moving parts.

Animation illustrating the principles of phased array scanning technology, focusing on the dynamic steering of beams through controlled phase shifts. Image courtesy of Wikipedia.

In phased array systems, the relative phase of the light emitted by each element in the array is adjusted to constructively and destructively interfere, steering the combined beam in the desired direction. This technology promises significant advantages in terms of speed and reliability, as the absence of moving parts reduces wear and maintenance needs and allows for almost instantaneous changes in beam direction.

Phased array scanning is being actively researched and developed for various advanced applications. In radar systems, it enables high-speed, precise targeting and tracking of objects, making it ideal for military and aerospace applications. In imaging systems, phased arrays can provide high-resolution, real-time images without the lag associated with mechanical scanning methods. Other potential applications include optical communication systems, where fast and precise beam steering can enhance data transmission rates and reliability, and in medical imaging, where non-invasive, high-resolution scanning is crucial.

As research progresses, phased array scanning could revolutionize many fields by providing faster, more accurate, and more reliable laser beam control than ever before.

3. Technical Specifications and Features

The following are the key technical specifications and features of laser scan heads – essential for selecting the right model for your application:

Speed and Precision: Laser scan heads are designed to move laser beams quickly and accurately. Speed refers to how fast the scan head can move the laser beam across a surface, measured in points per second (pps) or radians per second. Precision indicates the exactness of the beam’s positioning, which is critical for applications requiring high accuracy, such as medical procedures and fine engraving.

Resolution and Accuracy: Resolution is the smallest measurable movement of the laser beam, often defined in micrometers (µm) or dots per inch (dpi). Higher resolution means the scan head can make finer adjustments to the beam’s position. Accuracy refers to how closely the laser beam can be directed to a specified point. Both high resolution and accuracy are essential for tasks that require detailed work and precise control.

Field Size and Spot Size: Field size is the maximum area that the laser scan head can cover during operation, typically measured in millimeters (mm) or inches. Spot size is the diameter of the laser beam at the focal point. Smaller spot sizes allow for more detailed and precise work, while larger field sizes enable scanning over broader areas. Balancing these two factors is important depending on the application’s requirements.

Dynamic Focusing Capabilities: Dynamic focusing allows the laser scan head to maintain a sharp focus on the target surface even when the distance between the scan head and the target varies. This capability is crucial for scanning three-dimensional objects or surfaces with varying topographies. Dynamic focusing ensures consistent beam quality and processing accuracy across the entire working field.

Control Systems and Software Integration: Effective control systems and software integration are crucial for the seamless operation of laser scan heads. Control systems coordinate the laser beam’s movement and positioning using advanced algorithms for precise scanning. Software integration facilitates communication with other devices and systems, supporting complex processes like automated manufacturing and real-time data analysis. Opt for scan heads with robust software support and compatibility with industry-standard protocols.

4. Applications of Laser Scan Heads

Laser scan heads are versatile tools with a wide range of applications across various industries. Their ability to precisely control and position laser beams makes them invaluable in many high-tech processes. Below are some of the key applications where laser scan heads are used:

4.1. 3D Object Scanning

Laser scan heads play a crucial role in 3D object scanning by enabling detailed and accurate surface measurements. This capability is essential for creating precise 3D models of objects, buildings, and landscapes.

Lidar Technology: Laser scan heads are integral to lidar (Light Detection and Ranging) systems. They emit laser beams that reflect off surfaces, allowing the system to measure distances accurately. Lidar is used in mapping, autonomous vehicles, and environmental monitoring.

Mobile Mapping and Surveying: In mobile mapping, laser scan heads are mounted on vehicles to capture detailed 3D data of the surrounding environment. This technology is widely used in urban planning, construction, and infrastructure maintenance.

4.2. Material Processing

Laser scan heads are essential in material processing applications where precision and speed are critical. They enable high-quality cutting, engraving, and welding of various materials.

Laser Cutting, Engraving, and Welding: Laser scan heads are used to direct laser beams with high precision for cutting, engraving, and welding materials. They provide the accuracy needed for intricate designs and robust material joins, commonly used in manufacturing and fabrication industries.

If you want to learn more about laser welding, check out our brief guide to laser welding.

Rapid Prototyping and Laser 3D Printing: In rapid prototyping and 3D printing, laser scan heads control the laser beams to build up layers of material accurately. This allows for the creation of detailed prototypes and parts, speeding up the design and manufacturing process.

4.3. Barcode Readers

Laser scan heads are used in barcode readers to quickly and accurately scan barcodes from various distances. This application is vital in retail, logistics, and inventory management for efficient tracking and identification of products.

4.4. Space Flight

In space flight, laser scan heads are used for precise maneuvering and docking of spacecraft. They scan the target structure, enabling the onboard computer to calculate and execute accurate movements. This technology is crucial for successful space missions and satellite operations.

4.5. Laser Shows

Laser scan heads create visually stunning laser shows by rapidly moving laser beams to form patterns and images. These shows are popular in entertainment and promotional events, where dynamic and captivating visuals are needed.

Did you know, FindLight has a comprehensive product category for Entertainment Light Solutions.

Each of these applications showcases the versatility and importance of laser scan heads in modern technology and industry.

5. Industry Use Cases

Laser scan heads are employed in various industries to enhance precision, efficiency, and quality. Their ability to accurately control laser beams makes them essential in several high-tech manufacturing and processing applications. Below are some of the prominent industry use cases:

5.1. Medical Device Manufacturing

In the medical device manufacturing industry, laser scan heads are used to produce high-precision components and instruments. The accuracy and control provided by these devices ensure that medical tools meet stringent quality standards.

- Microsurgery Tools: Laser scan heads create intricate and precise tools for microsurgery, enabling minimally invasive procedures.

- Implant Manufacturing: High-precision laser cutting and engraving are used to produce implants with exact dimensions and smooth surfaces.

5.2. Electronics Manufacturing

The electronics industry relies heavily on laser scan heads for the production of components that require fine detail and precision. These devices are crucial for the fabrication of modern electronic devices.

- Printed Circuit Boards (PCBs): Laser scan heads are used for cutting and engraving PCBs, ensuring precise pathways for electrical connections.

- Semiconductor Production: They enable the precise etching and patterning required in semiconductor manufacturing, essential for creating microchips and other electronic components.

5.3. Additive Manufacturing

Additive manufacturing, or 3D printing, benefits significantly from the precision of laser scan heads. These devices enable the accurate layering of materials to build complex structures.

- Rapid Prototyping: Laser scan heads facilitate the quick creation of prototypes, allowing for faster design iterations and development.

- Custom Parts Production: They are used to produce custom parts with high precision, essential for specialized applications in various industries.

5.4. Aerospace and Automotive Industries

In aerospace and automotive manufacturing, laser scan heads are used for tasks that require high precision and durability. These industries demand components that can withstand extreme conditions and perform reliably.

- Component Fabrication: Laser scan heads are used to cut and shape high-strength materials, producing components that meet stringent safety and performance standards.

- Surface Treatment: They are employed in surface treatments, such as laser hardening and texturing, to enhance the durability and functionality of parts.

Each of these use cases highlights the critical role laser scan heads play in advancing technology and manufacturing processes across different industries. Their precision, speed, and versatility make them indispensable tools in modern industrial applications.

6. Buying Guide: How to Choose the Right Laser Scan Head

Choosing the right laser scan head for your application involves careful consideration of several factors. This guide will help you understand your requirements, compare different models, and evaluate key performance metrics to make an informed decision.

6.1. Understanding Your Requirements

The first step in selecting a laser scan head is to clearly define your application requirements. Consider the following questions:

- What is the primary use of the laser scan head?

- What level of precision and accuracy is needed?

- What are the size and nature of the workpieces or materials you will be working with?

- Do you need 2D, 3D, or more complex scanning capabilities?

Having a clear understanding of your specific needs will help narrow down the options and focus on the models that best fit your application.

6.2. Comparing Different Models

When comparing different laser scan head models, it is important to understand the capabilities and limitations of each type.

2D vs. 3D vs. 5D Scan Heads:

- 2D Scan Heads: Suitable for applications requiring movement along two axes (X and Y). Common in simple engraving, marking, and cutting tasks.

- 3D Scan Heads: Add control over the Z-axis, allowing for dynamic focusing. Ideal for 3D object scanning, medical applications, and any task involving varying surface heights.

- 5D Scan Heads: These advanced systems offer additional degrees of freedom, such as rotation and tilt, providing even greater control and flexibility for complex applications.

6.3. Evaluating Performance Metrics

When evaluating laser scan heads, consider the following key performance metrics:

- Speed: Measured in points per second (pps) or radians per second. Higher speeds are beneficial for tasks requiring rapid scanning.

- Precision: The ability to accurately position the laser beam. Essential for detailed and high-accuracy applications.

- Stability: Ensures consistent performance over time, reducing the risk of errors or deviations during operation.

6.4. Integration with Existing Systems

Consider how the laser scan head will integrate with your existing systems. Compatibility with current software, control systems, and other equipment is crucial for seamless operation. Ensure the scan head supports the necessary communication protocols and can be easily integrated into your workflow.

6.5. Cost vs. Benefit Analysis

Perform a cost vs. benefit analysis to determine the value of the investment. Consider the following:

- Initial Cost: The upfront price of the laser scan head.

- Operational Costs: Maintenance, power consumption, and potential downtime.

- Benefits: Increased productivity, improved quality, and potential for new capabilities.

Balancing these factors will help you choose a laser scan head that offers the best return on investment for your specific application.

By following this guide, you can make a well-informed decision when selecting a laser scan head, ensuring it meets your requirements and enhances your operational capabilities.

7. Maintenance and Troubleshooting

Proper maintenance and effective troubleshooting are essential for ensuring the long-term performance and reliability of laser scan heads. Regular maintenance involves cleaning the optical components, checking for alignment, and inspecting the mechanical parts for wear and tear. It’s important to follow the manufacturer’s guidelines for maintenance intervals and procedures to prevent any degradation in performance. Regular calibration of the scan head is also crucial to maintain its accuracy and precision.

Common issues with laser scan heads include alignment problems, degraded beam quality, and mechanical failures. Alignment issues can often be resolved by recalibrating the system and ensuring that all optical components are correctly positioned. Degraded beam quality might be due to dirty or damaged optics, which can be cleaned or replaced as needed. Mechanical failures, such as worn-out galvanometers or motors, require inspection and replacement of the faulty parts. Keeping a log of any issues and their resolutions can help in diagnosing recurring problems and implementing preventive measures.

Upgrading and replacing components is sometimes necessary to keep the laser scan head functioning optimally. This may involve updating software, replacing worn-out parts, or integrating new technologies to enhance performance. When upgrading, it is important to ensure compatibility with existing systems and to follow the manufacturer’s recommendations. Regularly reviewing the performance of the scan head and staying informed about advancements in technology can help you make timely decisions about upgrades and replacements, thereby extending the lifespan of your equipment and maintaining high productivity.

Conclusion

Laser scan heads are critical components in various industrial applications, offering precision and versatility in tasks such as 3D object scanning, material processing, and manufacturing. Key points covered in this guide include the different types of scan heads (1-Axis, 2-Axis, 3-Axis), the technologies behind them (scanning mirrors, acousto-optic and electro-optic deflectors, phased array scanning), and their specific applications across industries like medical device manufacturing, electronics, and aerospace.

Looking to the future, advancements in laser scan head technology are going to focus on increasing speed, precision, and integration capabilities. Emerging technologies such as phased array scanning and improvements in dynamic focusing modules promise to enhance performance and open new possibilities for complex applications. Additionally, ongoing research into more efficient and cost-effective materials and methods will likely drive innovation, making laser scan heads even more accessible and versatile.

In final thoughts and recommendations, it is crucial to thoroughly assess your specific requirements and application needs when selecting a laser scan head. Consider factors such as speed, precision, integration, and cost-effectiveness to ensure the best fit for your operations. Regular maintenance and staying updated with technological advancements will help you maximize the performance and lifespan of your laser scan heads, ensuring continued efficiency and productivity in your applications.

References

For a deeper understanding of laser scan heads and their applications, consider reviewing the following sources and further reading materials:

- Marshall, Gerald F. Handbook of Optical and Laser Scanning. Marcel Dekker, Inc., 2004. ISBN 0-8247-5569-3.

- Dassot, M., Constant, T., & Fournier, M. “The use of terrestrial LiDAR technology in forest science: application fields, benefits and challenges.” Annals of Forest Science, 68(5), 959-974, 2011.

- Wikipedia contributors. “Laser scanning.” Wikipedia, The Free Encyclopedia. Available at: https://en.wikipedia.org/wiki/Laser_scanning

- Wikipedia contributors. “3D scanning.” Wikipedia, The Free Encyclopedia. Available at: https://en.wikipedia.org/wiki/3D_scanning

- Novanta. Technical specifications and application notes on the LIGHTNING™ II 3-Axis Digital Scan Head. Available at FindLight Marketplace.

These references provide comprehensive information on the principles, technologies, and applications of laser scan heads, supporting a deeper exploration into this field.