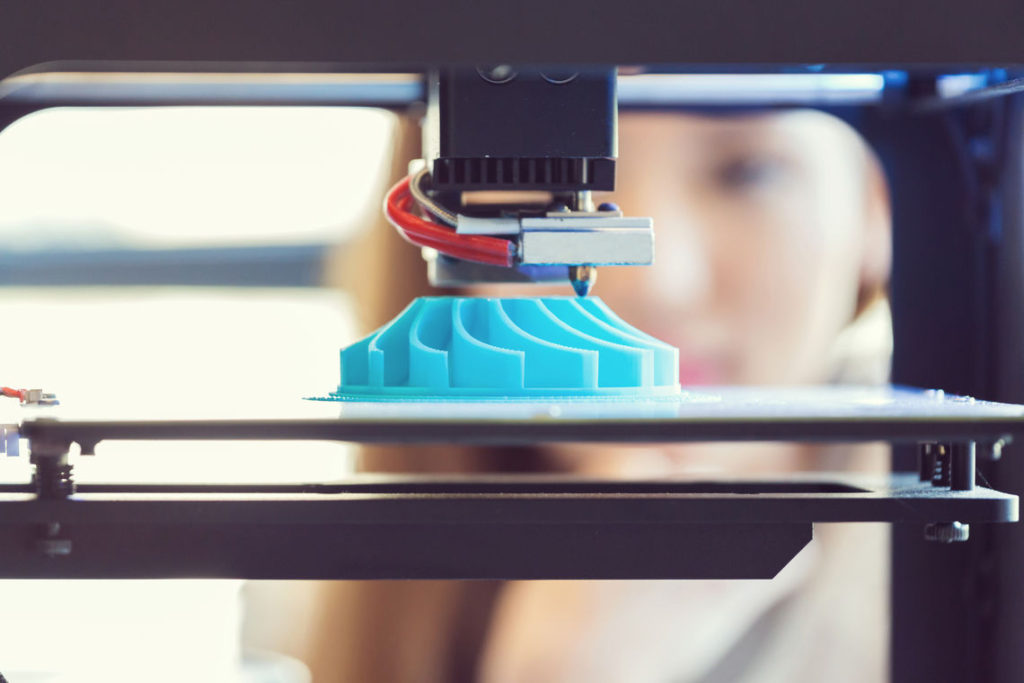

Many different types of technologies, such as 3D printers, rely on motion control to operate. Courtesy of TRINAMIC.

Introduction to Motion Control Instrumentation

Motion control is the combination of mechanics and electronics to regulate the position, speed and acceleration of moving parts in a controlled manner. It is a part of our everyday lives, but also plays a crucial role in industries like medicine, robotics, and manufacturing, among many others. Advancements in technology have resulted in developed instrumentation with greater speed and precision than ever before. It is safe to say that in our highly technical society, it has never been as important for parts to move exactly as planned or for an object to be in the right place at precisely the right time. Today, all of this is possible thanks to advanced motion control systems.

Advancements in Motion Control

Not long ago, motion control was largely hardware based. Controllers were bulky and slow in performance. However, engineers and designers pushed the boundaries of motion control automation with solid-state electronics, computers, and microprocessors. Today, the technology sector is developing exponentially and creating precise, accurate, and high-speed instrumentation is suddenly within reach.

In the past, motion control technology utilized basic microprocessors in order to calculate and execute motion algorithms. However, with the development of a new microprocessor, the digital signal processor (DSP), motion control has significantly improved. DSPs emerged five to six years ago primarily for speech and video processing applications. Using DSPs, motion control systems can now complete motion algorithms up to ten times faster than before.

Modernized control systems utilize DSPs for improved operating speeds. Courtesy of SCHMID Electronic.

In addition, the demand for higher precision motion control has led to many new innovations to create motion. The use of piezoelectric materials, like quartz, is one of these innovations. Piezoelectric materials display a unique characteristic, called the piezoelectric effect, which is the ability for certain materials to generate an electric charge in response to an applied mechanical stress. These applied stresses translate to very small changes in crystal width. Thus, the manipulation of crystal width results in extremely high precision. In fact, piezoelectric materials may achieve incredibly fine position changes down to the sub-nanometer range.

Applications

From conveyors and fans to printers and elevators, motion control is a necessity in most fields. Some examples of industries that benefit most from motion control instrumentation are the photonics and optics, manufacturing, and medical industries.

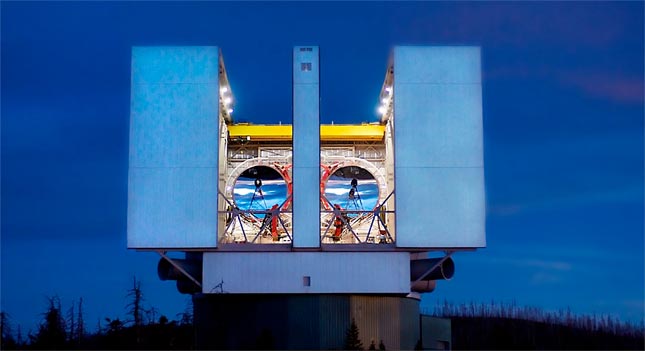

In optics and photonics, refined motion control translates to advanced image stabilization, scanning microscopy, laser tuning, interferometry, and many more. It has also been implemented in a variety of instruments, such as in telescopes, to improve image quality. Astronomers, for example, are particularly interested in viewing distant galactic systems and stars. The Large Binocular Telescope (LBT), fundamentally an over-sized pair of binoculars, relies on motion control to provide high-resolution images. In order to achieve such high quality images, the optical assemblies within the LBT require positioning with an accuracy of 5 µm. Motion control instrumentation is the key component in executing nanoscale positioning.

Optical instrumentation, such as the LBT, utilizes motion control to execute extremely small positioning movements. Courtesy of National Optical Astronomy Observatory.

Additionally, motion control has become increasingly important in the manufacturing field. Digital technologies, such as 3D printing, laser cutting, and Computer Numerical Control (CNC) milling, have become more mature and accessible. Furthermore, they require specialized and advanced positioning technology. For example, 3D printing, which refers to the methods and processes of creating and modeling various objects, requires accurate positioning on X-Y-Z axes to create a final product.

Many medial applications also require high levels of control to guarantee the utmost safety to patients. Additionally, state of the art medical technology relies on motion control to solve some of society’s most pressing health issues. For example, surgeons treating brain cancer are able to capture high-resolution photos of a brain tumor using Magnetic Resonance Imaging (MRI) and use ultra-precise tools to remove it. However, they do not yet have the tools to do both simultaneously. Today, scientists are working on developing a surgical robot designed to collaborate with MRI machines. Using motion control, the robot positions a high-energy, focused ultrasound probe exactly at the tumor, delivering optimal surgical results.

Market Size

In the last few years, the demand for motion control instrumentation has increased following the improved price and performance of microprocessors, DSPs, and programmable logic devices. Advanced and automated factory processes and an increasing demand for industrial robots in manufacturing are key factors driving the expanding market. Experts valued the motion control market at $15.65 Billion in 2015 and expect an increase of 5.5% by 2022. Some of the biggest contributors to this market include motors, the packaging industry, robotics and the semiconductor and electronics industry.

Motors contribute largely to this market with the growing use of electric motors and automation, along with the increasing demand for energy-efficient equipment. Motors find application just about everywhere, including aircrafts, compressors, pumps, military missiles, factories, and industrial operations. Additionally, packaging is another major player in the growing market due to position-dependent processes like sealing, labeling, shrink-wrapping, etc.

Packaging, a major contributor in the motion control market, requires precise positioning technology for a variety of different processes. Courtesy of Bauer Compressors.

Furthermore, an increasing demand for robotics will also contribute to growth, reaching $23.90 billion by 2022. This includes applications for industrial settings, military operations and even companies like Amazon that are looking to increase the role of robotics in warehouses and product delivery. The final key contributor, the semiconductor and electronics industry, will display the highest growth rate before 2022. These products require high accuracy and precision, and with the increasing complexity in the semiconductor and electronics manufacturing industry, the need for sophisticated motion controllers has become increasingly important.

Overall, motion control requirements will continue to increase, and become more specialized and complex. As consumers require greater speed, accuracy and precision for various industries and applications, the market continues to grow and expand to meet those demands.