Description

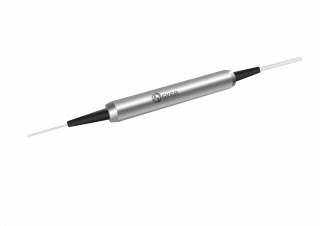

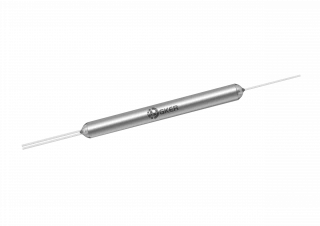

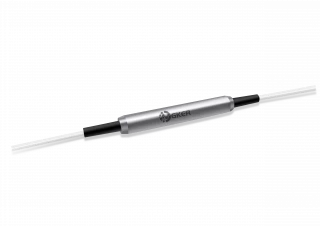

The GKER Photonics 488-2100 nm Polarization Maintaining Fused Coupler (GK-PMC Series) is a highly advanced optical component engineered for precision and reliability across a broad range of wavelengths. Designed to meet the demanding needs of modern optical systems, this coupler delivers exceptional performance with low excess loss and high extinction ratios, ensuring that your signal integrity is maintained even in challenging environments. Whether used in power monitoring, fiber amplifiers, or coherent communication systems, this coupler offers unparalleled stability and flexibility.

The GK-PMC Series is available with a wide range of customizable options, including various coupling ratios from 0.01/99.99 to 50/50, allowing for precise control over power distribution. Its ability to handle high optical power with excellent thermal stability makes it suitable for both continuous wave and high-power pulse applications. The coupler is compatible with both PM and singlemode fibers, providing versatility for a wide range of applications. With multiple configurations, connector types, and fiber jacket options, the GK-PMC Series can be tailored to meet the specific needs of any optical system.

Engineered for high stability and reliability, this coupler is an essential component for applications such as fiber gyroscopes, laser test equipment, and fiber amplifiers, where maintaining signal polarization and minimizing loss are critical. The GKER Photonics GK-PMC Series is your go-to solution for high-performance optical coupling, ensuring consistent and reliable operation in the most demanding environments.

488 - 2100 nm Polarization Maintaining Fused Coupler

Specifications

| Type: | Other / Not Specified |

|---|---|

| Configuration: | 1x2 |

| Splitting Ratio: | Other / Not specified |

| Wavelength: | 488 nm |

| Fiber Type: | SMF-28e |

| Connector Type: | Other / Not specified |

| Housing Material: | Other / Not specified |

| Center Wavelength (λc): | 488, 532, 635 780,830 980,1064 1310, 1480, 1550 1700, 2000 nm |

| Operating Wavelength: | λc ± 5 λc ± 10 λc ± 10 λc ± 20 λc ± 20 nm |

| Typ. Excess Loss: | 0.8 0.5 0.4 0.2 0.5 dB |

| Max. Excess Loss: | 1.2 0.8 0.6 0.4 0.8 dB |

| Min. ER¹: | 18 18 20² 20 20 dB |

| Max. Excess Loss For Each Connector: | 1.5 0.7 0.5 0.3 0.3 dB |

| Max. Optical Power (Continuous Wave): | 2 W |

| Thermal Stability: | ≤ 0.005 dB/℃ |

| Min. Return Loss: | 50 dB |

| Min. Directivity: | 50 dB |

| Fiber Type For Signal Port: | PM Fiber - |

| Fiber Type For Tap Port: | PM Fiber, or Singlemode Fiber - |

| Operating Temperature: | - 5 to + 70 ℃ |

| Storage Temperature: | - 40 to + 85 ℃ |

| Coupling Ratio: | 1/99 , 2/98, 5/95,10/90,20/80,30/70 40/60,50/50 % |

| Max. Coupling Ratio Tolerance, λc: | ±0.3 ±0.5 ±0.7 ±1.0 ±2.0 ±2.0 ±2.5 ±3.0 % |

| Coupling Ratio: | 0.1/99.9 0.01/99.99 % |

Features

- Wide Wavelength Range: Operates from 488 nm to 2100 nm, suitable for various applications

- High Stability and Reliability: Designed for consistent performance in challenging environments

- Low Excess Loss: Minimizes signal degradation for high-quality transmission

- High Power Handling: Capable of managing high optical power with continuous wave operation

- Flexible Coupling Ratios: Available from 0.01/99.99 to 50/50 for tailored power distribution

- Polarization Maintaining: Maintains signal polarization, essential for precision applications

- Customization Options: Various connector types, fiber jackets, and lengths available

Applications

- Power Monitoring: Efficiently monitors power levels in optical communication systems

- Fiber Amplifiers: Enhances signal strength while maintaining polarization integrity

- Fiber Gyroscopes: Essential in precision navigation and sensing applications

- Coherent Communication: Maintains high signal quality in complex communication networks

- Fiber Laser Test Equipment: Ideal for testing and measurement in high-power laser systems

Frequently Asked Questions

What is the operating wavelength range of the GK-PMC Series Coupler?

What coupling ratios are available for this coupler?

What types of fibers are compatible with the GK-PMC Series Coupler?

How does the coupler maintain polarization?

What is the maximum optical power the coupler can handle?

What is the thermal stability of the GK-PMC Series Coupler?

What are the typical and maximum excess losses for this coupler?

Can the coupler operate on both fast and slow axes?

What are the environmental operating conditions for the coupler?

How customizable is the GK-PMC Series Coupler?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle