Description

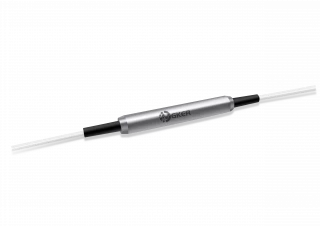

Introducing the SeasonBeam - Wide Temperature Range Fiber Laser Isolator, a cutting-edge solution designed to revolutionize fiber laser technology. Engineered with precision and innovation, this isolator is crafted to excel in the most demanding environments, ensuring unparalleled performance and reliability across a wide temperature range.

From scorching heat to freezing cold, the SeasonBeam Isolator maintains laser performance with unwavering consistency, thanks to its patented design and advanced thermal management system.

Whether you're operating in the blistering heat of summer or the frigid cold of winter, the SeasonBeam Isolator is your steadfast companion, delivering stable and reliable laser performance when you need it most.

1064nm 20-100W Wide Temperature Range Fiber Laser Isolator

Specifications

| Type Of The Device: | Isolator |

|---|---|

| Operating Wavelength: | 1064 nm |

| Max Power: | 20 W |

| Min Isolation: | 30 dB |

| Center Wavelength (λc): | 1064 ±15 nm |

| Min. Isolation At 23 ℃, λc All Polarization States: | 35 dB |

| Min. Isolation At All Temperature, λc All Polarization States: | 30 dB |

| Nominal Output Beam Diameter (1/e2 ): | 7.0 ±0.5 mm |

| Max. Average Optical Power: | 20-100 W |

| Max. Peak Power For Ns Pulse: | 35 kW |

Features

- Wide Temperature Range Operation: Capable of operating in temperatures ranging from 0°C to +55°C, ensuring consistent performance in varying environmental conditions

- Patented Isolation Design: Employs patented technology to maintain high isolation levels, safeguarding laser performance even in extreme temperature fluctuations

- Compatibility with SteadiBeam Technology: Compatible with SteadiBeam technology enabling integration with higher power isolators to eliminate thermal lensing effects and ensure stable laser performance

- Precision Output Beam: Nominal output beam diameter of 7.0 ± 0.5 mm ensures precise laser output, crucial for applications requiring accuracy and consistency

- Excellent Beam Circulariry: Achieves over 90% beam circularity, ensuring uniform and consistent laser beam profiles for reliable operation

- Low M^2 Degradation: Maintains M^2 degradation below 10%, preserving laser beam quality and minimizing performance degradation over time

- Armoured Cable Jacket: Equipped with a durable armoured cable jacket for enhanced protection and longevity in demanding industrial environments

- Multiple Handling Power Options: Available in handling powers ranging from 20 W to 100 W, catering to a wide range of laser power requirements

Applications

- Fiber Laser Systems: Ideal for integration into fiber laser systems operating in environments with temperature fluctuations, ensuring stable and reliable laser performance

- Industrial Laser Cutting, Welding, and Marking: Suited for industrial laser applications such as cutting, welding, and marking, where precise and consistent laser performance is essential

- Research and Development Laboratories: Used in research and development laboratories requiring stable laser performance for experiments and prototyping

- Defense and Aerospace: Deployed in defense and aerospace applications for laser-based sensing, communication, and targeting systems, where reliability and stability are paramount

- Medical Laser Systems: Utilized in medical laser systems for precision surgeries, treatments, and therapeutic applications, where consistent laser performance is critical for patient safety and treatment efficacy

Frequently Asked Questions

What is the operating temperature range of the SeasonBeam Isolator?

How does the SeasonBeam Isolator ensure stable laser performance in varying temperatures?

Is the SeasonBeam Isolator compatible with higher power isolators?

What beam characteristics does the SeasonBeam Isolator offer?

What are the available handling power options for the SeasonBeam Isolator?

What types of fiber can be used with the SeasonBeam Isolator?

In what applications can the SeasonBeam Isolator be used?

What is the storage temperature range of the SeasonBeam Isolator?

Is the SeasonBeam Isolator suitable for harsh industrial environments?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle