Description

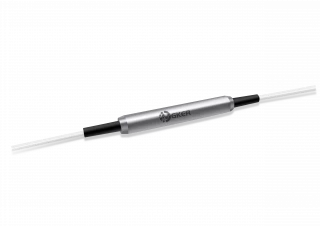

Designed to bridge the gap between fiber and free-space optical systems, the 1064 nm Fiber to Free Space High Power Isolator stands out for its precision engineering and high-performance capabilities. This device is ideal for applications in fiber lasers and advanced instrumentation, where maintaining the integrity and quality of the light beam is paramount.

Featuring a center wavelength of 1064 nm, the isolator boasts exceptional optical properties including low insertion loss of only 0.5 dB and high peak isolation of 35 dB, ensuring minimal signal degradation and maximum protection against back reflections. The isolator is designed to handle high power levels, capable of managing 30 watts of average optical power and peak powers up to 10 kW for nanosecond pulses, making it suitable for a wide range of high-intensity applications.

The device also excels in maintaining excellent beam quality with minimal M2 degradation and high beam roundness, ensuring that the laser output remains focused and precise. The minimum extinction ratio of 20 dB further enhances its capability to maintain the polarization of the beam, crucial for polarization-sensitive applications.

1064nm 30W PM Fiber to Free Space Isolator

Specifications

| Type Of The Device: | Isolator |

|---|---|

| Operating Wavelength: | 1064 nm |

| Max Power: | 30 W |

| Min Isolation: | 28 dB |

| Center Wavelength (λc): | 1064 nm |

| Typ. Peak Isolation: | 35 dB |

| Min. Isolation, 23 ℃, λc: | 28 dB |

| Min. Extinction Ratio: | 20 dB |

| Max. Average Optical Power: | 30 W |

| Max. Peak Power For Ns Pulse: | 10 kW |

| Fiber Type (Input Port): | PM 980 Panda Fiber |

| Fiber Type (Output Port): | Free Space |

Features

- Low Insertion Loss (0.5 dB): Ensures minimal power loss during transmission, crucial for maintaining high efficiency in critical applications.

- High Isolation (35 dB): Provides robust isolation to protect against feedback and signal degradation, essential for stable laser operation.

- High Power Handling: Capable of managing up to 30 watts of average optical power and peak powers up to 10 kW for nanosecond pulses, suitable for various high-power applications.

- High Return Loss (50 dB): Minimizes signal leakage back into the laser source, enhancing the overall system performance.

- Excellent Extinction Ratio (20 dB): Ensures effective polarization maintenance, critical for applications requiring precise polarization control.

- Minimal M2 Degradation and High Beam Roundness: Maintains superior beam quality, which is crucial for applications requiring precise focus and consistent beam profile.

- Environmental Stability and Reliability: Operates effectively within a temperature range of +10°C to +50°C, ensuring performance stability under varying environmental conditions.

- Customizable Configuration: Offers options for fiber type, fiber jacket, fiber length, and power type, allowing adaptation to specific system requirements.

- Output Beam Size (7 ± 0.5 mm): Suitable for applications requiring a specific focus size for integration into free-space optical systems.

Applications

Fiber laser and instrumentation applications

Frequently Asked Questions

What is a 1064 nm Fiber to Free Space High Power Isolator?

How does the Fiber to Free Space Isolator enhance fiber laser systems?

What are the benefits of high isolation in this isolator?

Can the 1064 nm Isolator handle different power levels?

What are the key features of the 1064 nm High Power Isolator?

Where is the 1064 nm High Power Isolator typically used?

What does high return loss mean for the 1064 nm Isolator?

How does the isolator’s environmental stability benefit its applications?

What customization options are available for the 1064 nm Isolator?

Similar Products

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle