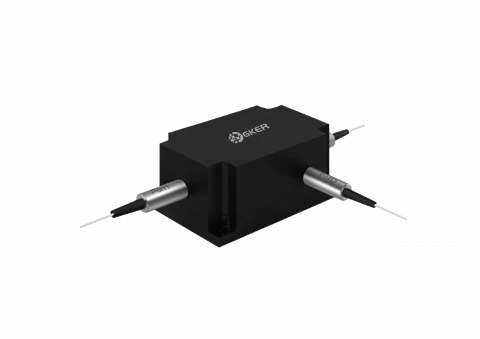

1030/1064nm 20W Polarization Maintaning Tap Isolator

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

-

On FindLight:

since 2024

Description

The High Power Polarization Maintaining Tap Isolator sets a new standard for precision and efficiency in advanced optical systems. Specifically engineered for applications that require a balance of high power handling and precise light management, this isolator is ideal for integration into fiber laser systems and sophisticated instrumentation.

Operating at center wavelengths of 1030 nm and 1064 nm, this device is tailored for versatility across a broad range of optical applications. It features exceptionally low insertion loss and high isolation levels, which are crucial for maintaining signal integrity and minimizing noise in sensitive setups. With its ability to handle up to 20 watts of average optical power and peak powers for nanosecond pulses up to 10 kW, the isolator is robust enough for the most demanding applications.

One of the standout features of the HPMTI Series is its customizable tap ratios, ranging from 0.1% to 10%, which allow precise control over the division of power between the main line and tap line, making it suitable for applications requiring signal monitoring or feedback without disrupting the main signal path.

1030/1064nm 20W Polarization Maintaning Tap Isolator

Specifications |

|

|---|---|

| Type Of The Device: | Isolator |

| Operating Wavelength: | 1030 nm |

| Max Power: | 20 W |

| Min Isolation: | 25 dB |

| Center Wavelength (λc): | 1030, 1064 nm |

| Operating Wavelength Range: | λc ± 10 nm |

| Min. Extinction Ratio: | 20 dB |

| Min. Isolation, λc, 23 ℃, All Polarization States: | 25 dB |

| Max. Average Optical Power: | 20 W |

| Max. Peak Power For Ns Pulse: | 10 kW |

Features

- Low Insertion Loss (0.8 dB Typical): Ensures minimal power loss during transmission, crucial for maintaining efficiency in high-power laser systems.

- High Isolation (25 dB Minimum): Provides robust isolation to protect against feedback and signal degradation, essential for stable laser operation.

- High Return Loss (45/45 dB): Minimizes signal leakage back into the laser source, enhancing the overall system performance.

- High Power Handling: Capable of managing up to 20 watts of average optical power and peak powers up to 10 kW for nanosecond pulses, suitable for various high-power applications.

- Adjustable Tap Ratios (0.1% to 10%): Allows for precise control over the division of power between the main line and tap line, ideal for applications requiring signal monitoring or feedback.

- Excellent Extinction Ratio (20 dB for PM type): Ensures effective polarization maintenance, critical for applications requiring precise polarization control.

- Environmental Stability and Reliability: Operates effectively within a wide temperature range (10°C to 50°C), ensuring performance stability under varying environmental conditions.

- Customizable Configuration: Offers options for fiber type, fiber jacket, and fiber length, allowing adaptation to specific system requirements.

Applications

- Laser Monitoring and Control Systems: Utilized in laser systems to tap a small portion of the laser signal for monitoring and feedback control without disrupting the main power flow. This is crucial for maintaining optimal laser performance and safety in precision applications.

- Telecommunications: Enhances optical communication systems by allowing part of the signal to be tapped for monitoring or routing purposes while maintaining the integrity of the main signal. This is particularly useful in long-distance fiber-optic networks.

- Medical Instrumentation: Used in medical laser systems, such as those employed in surgical and diagnostic applications, where precise power control and signal integrity are necessary for effective and safe operations.

- Research and Development: Provides a critical tool in R&D labs working with high-power lasers, where monitoring laser characteristics without disturbing the main beam is essential for experimental accuracy and development of new laser technologies.

- Industrial Processing: Integral in manufacturing processes that use lasers for cutting, welding, or materials processing. The isolator allows for real-time power monitoring and control, enhancing process reliability and product quality.

- Military and Aerospace: Used in military and aerospace applications for laser-based communication and targeting systems, where reliable signal handling and precise control are vital for operational success.

- Optical Sensing Systems: Assists in optical sensing technologies by facilitating the tapping of laser signals for sensing while maintaining the main signal's power and integrity, critical in environmental monitoring and industrial automation.

Frequently Asked Questions

The High Power Polarization Maintaining Tap Isolator is a specialized optical device designed to tap off a small portion of a light signal for monitoring or feedback while maintaining the main signal's integrity and polarization. It is crucial for systems requiring precise control over laser output.

It enhances laser monitoring systems by allowing a small part of the laser signal to be diverted for monitoring and control purposes without significantly affecting the main signal's power and quality. This is essential for maintaining optimal performance and safety in laser applications.

High isolation in the Tap Isolator prevents back reflections and signal leakage, which are critical for protecting the laser source and ensuring stable and reliable operation in sensitive optical setups.

Yes, the Tap Isolator is capable of handling up to 20 watts of average optical power and can manage peak powers up to 10 kW for nanosecond pulses, making it suitable for a variety of demanding applications across multiple industries.

Key features include low insertion loss, high isolation, adjustable tap ratios, high return loss, and excellent environmental stability. These features make it ideal for precision applications where signal integrity is paramount.

It is typically used in fiber laser systems, telecommunications, medical instrumentation, research and development, industrial processing, military and aerospace applications, and optical sensing systems.

High return loss in the Tap Isolator means it effectively prevents the laser signals from leaking back to the source, which enhances system efficiency and safety by reducing potential interference and damage.

The isolator’s capability to operate within a wide temperature range ensures reliable performance under varying environmental conditions, which is essential for applications in fields like medical technology and aerospace systems where operational reliability is critical.

The Tap Isolator offers various customization options including different tap ratios, fiber types, fiber jackets, connector types, and power types, allowing it to be tailored to meet specific requirements of different optical systems.